I don't know if I can describe what I mean but I'll try. Weld a top on the long portion of the verticals and have it turn down to the lower before it gets to the mount. Leave the mounting holes and bracket exposed as they are now. The top that I'm talking about would basically totally enclose the pocket you have exposed AND give you a location to drill/tap a hole or 2 should you decide to install a heat shield over the mount. If it were me, I'd trim the lower plate back to expose the bottom of the engine mount and weld the top portion that I'm thinking of to the bottom to form a ~90 degree angle, thereby eliminating another potential pocket for anything to collect in. It looks to me that the vertical sections should be plenty strong to support the engine for that short section. They don't really need the fore and aft reinforcement that the bottom plate provides. I applaud the thought of over building it that way, but it can also be a catch all for oil, water, mud, etc that could build up over time and sit right under your mount. By the looks of the thickness of the vertical supports you could add a top plate without interfering with the frame mounting bolts.

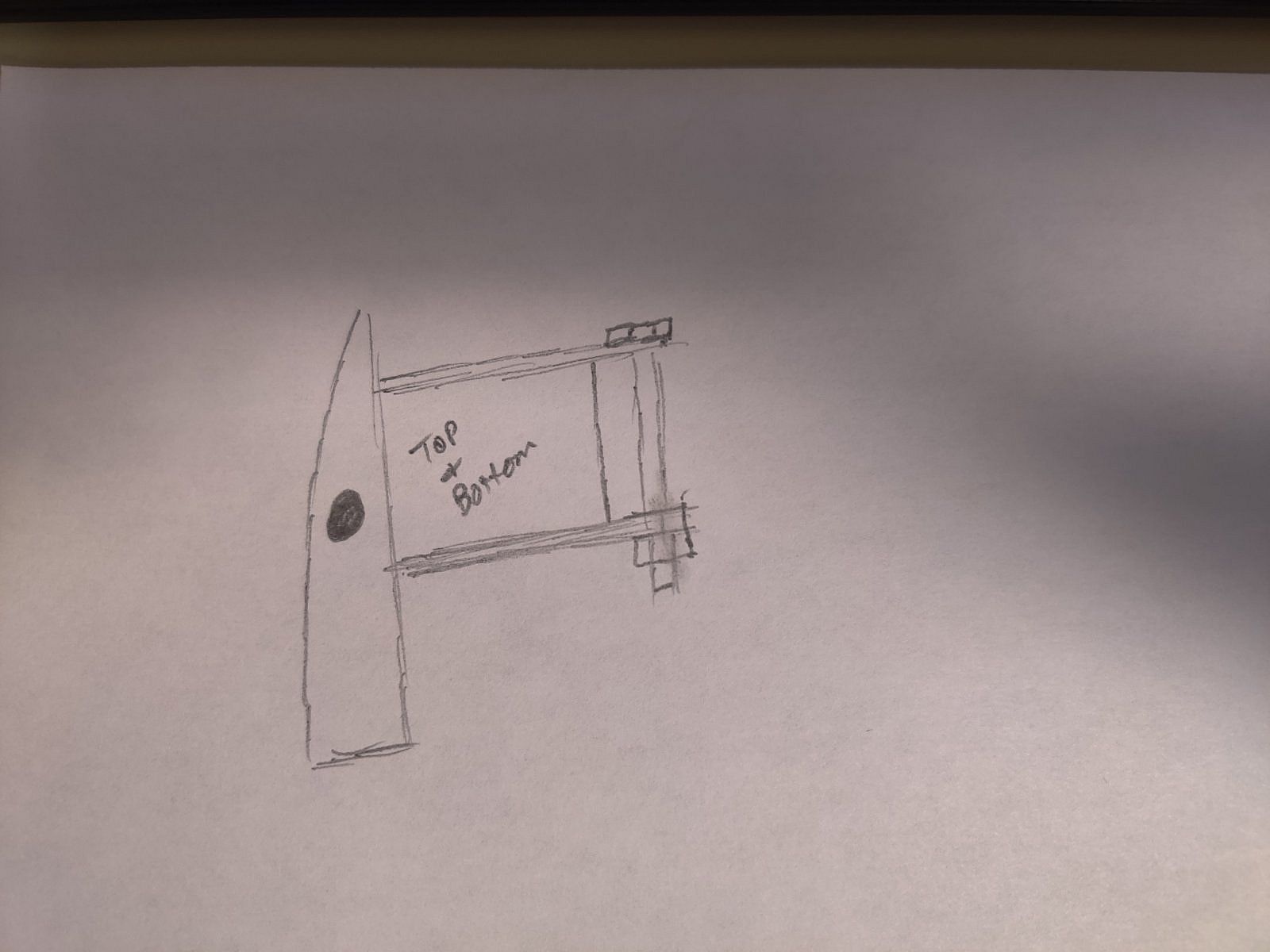

I tried to draw a sketch of what I'm thinking and I'm posting them as well.

Hopefully this will help explain better than my description....

I see exactly what your talking about here. Basically make a box with tabs out the end. That section would still have enough clearance to drop the frame side of the mount out with ease, still not a bad idea to make a hole for drainage on the lower section.

I have some 1/8" flat that I could form to the curve of the arms of the mount. Once I've got the second mount and cross member fabbed up I still need to pull the motor to do a little more work on it. When I do that I'll do the finish work on the mounts.

. Been looking up intercoolers and radiators, probably going with 18x20x3 on the rad and still looking into sizing the intercooler. Ill also have to get a new intake manifold as the truck manifold sits too high, the throttle body is where im starting to run into clearance issues. To make that work, Ill have to also get a water pump from a 2010+ camaro, and a tensioner as well seeing as thats mounted to the water pump.

. Been looking up intercoolers and radiators, probably going with 18x20x3 on the rad and still looking into sizing the intercooler. Ill also have to get a new intake manifold as the truck manifold sits too high, the throttle body is where im starting to run into clearance issues. To make that work, Ill have to also get a water pump from a 2010+ camaro, and a tensioner as well seeing as thats mounted to the water pump.

to poke the bear may be dangerous with his current mental state.

to poke the bear may be dangerous with his current mental state.