I'm working on the driver's floor on my 66 and am adding torque boxes. Right now I have the floor and toe board cut out. I have a 2 piece box I'm installing. Does the toe board side of the torque box weld to the engine side or the passenger compartment side of the front frame rail flange and does the toe board get welded to the torque box? I have searched the net for tips and have seen it done both ways, just wondering which is better. Also the torque box has a flange that is attached to the rocker and cowl side panel and the toe board's flange in that area is formed towards the engine side so there really isn't a way to weld it with the box in place. Should I bend the flange 180 degrees so it is in the passenger compartment? This is the first car I have restored and don't want to screw it up. Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question About Adding Front Torque Boxes To A 66 Coupe

- Thread starter 66Coupe289POWER

- Start date

-

Sponsors (?)

horse sence

15 Year Member

are you talking about the top plate or the front plate of the box? with the toe board out you should have access all the way around the box. the toe board does weld to the torque box. i am having troubles loading pics on stang net at the moment or i would post some. i have found that top plate may need some trimming at the top where it meets the fraim rail ,they are some times crooked and wont go in and you may have to trim the floor support at the small lip that turns out on the frame rail if you install the box in one piece ,so it will slide in. i will try to load pics again but i dont tnink it will.I'm working on the driver's floor on my 66 and am adding torque boxes. Right now I have the floor and toe board cut out. I have a 2 piece box I'm installing. Does the toe board side of the torque box weld to the engine side or the passenger compartment side of the front frame rail flange and does the toe board get welded to the torque box? I have searched the net for tips and have seen it done both ways, just wondering which is better. Also the torque box has a flange that is attached to the rocker and cowl side panel and the toe board's flange in that area is formed towards the engine side so there really isn't a way to weld it with the box in place. Should I bend the flange 180 degrees so it is in the passenger compartment? This is the first car I have restored and don't want to screw it up. Thanks

i think the flange you are talking about at the rocker is the one that is turned strait up and it comes through the toe board at the side panel ?the toe board is notched just enough for the flange to pass through

horse sence

15 Year Member

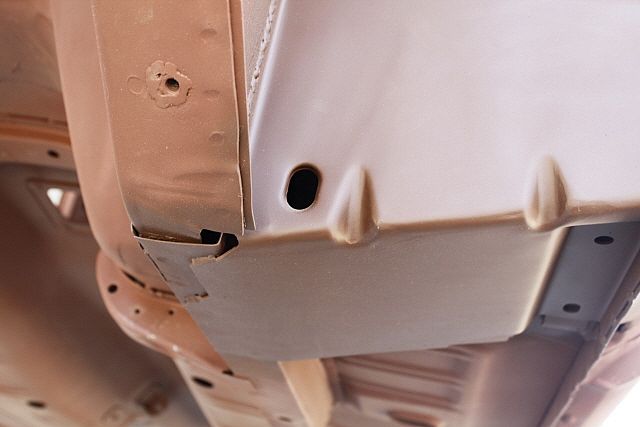

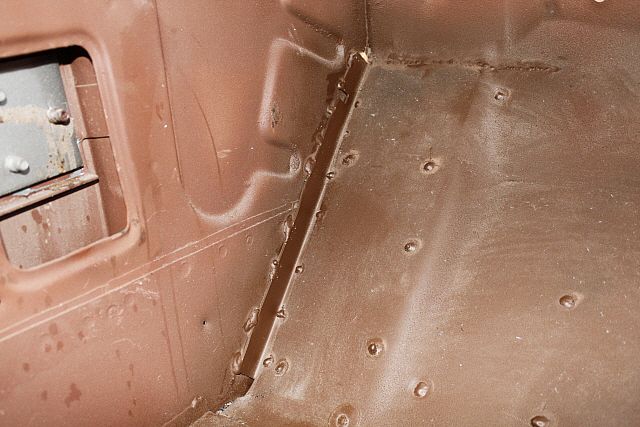

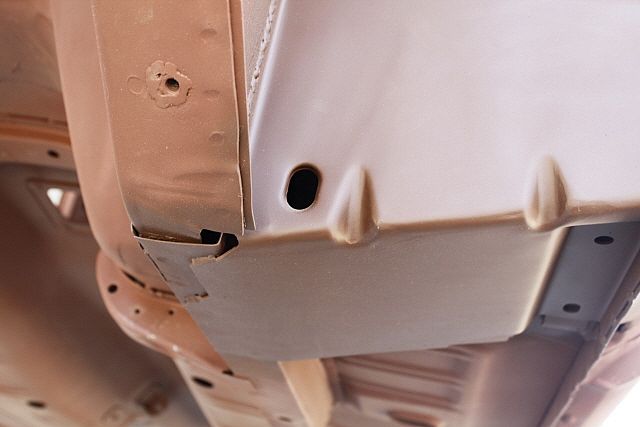

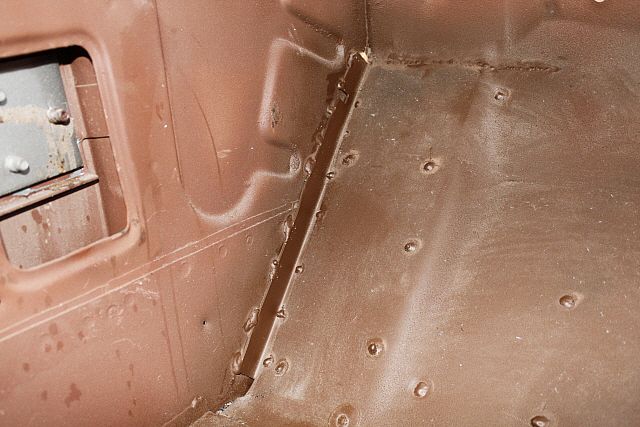

ok i think i see what you mean. the top plate of the torque box i usualy put under the flange at the top of the frame rail .if you put it on top it kind of holds the toe board up. if the toe boards are still in i cut a slot every inch were the flange over laps the torque box top through the toe board and weld all three pieces at the same time. you have the toe board out so not a problem just weld the flange to the top plate of the torque box then spotweld the toe board to the torque box. lets see if the pics will load this time, i know the weld at the top of the box do not look very pretty .my welder is a piece of ****.

Thanks, that last pic answered my question. The toe board I have has a flange that normally welds to the inner rocker and cowl side panel and will interfere with the torque box flange but in your pic that flange is cut off. Time to get some weld-thru and start burning some metal on!

horse sence

15 Year Member

i got you, the little angle at the side

my welder burns metal realy well ,or sputters ,pops .burns the wire back inside the tip.

my welder burns metal realy well ,or sputters ,pops .burns the wire back inside the tip.

I recently upgraded my welder to this one http://www.northerntool.com/shop/tools/product_200577737_200577737 It's not Miller or Lincoln quality but it works very well so far and it's spool gun ready just in case I ever want to try aluminum. The voltage and wire speed are infinitely adjustable vs 4 or 5 settings and it has a spot weld timer.

horse sence

15 Year Member

i bought my 50 inch sheet metal shear and 50 inch sheet metal break form Northern tools ,good tools.

my welder is a Miller 252 and i have hated it from the day i bought it. i used to have a snapon that i realy liked but i finaly burned it up.i am going to see if the welding shop will let me try out a spool gun on my miller every one here seems to like it better.

my welder is a Miller 252 and i have hated it from the day i bought it. i used to have a snapon that i realy liked but i finaly burned it up.i am going to see if the welding shop will let me try out a spool gun on my miller every one here seems to like it better.

One more question. While the driver's side floor and toe board is cut what would be the best way to support the car? Right now it's a shell with suspension so it doesn't weigh very much. I have 2 jackstands under the car at the front of the rockers where the factory jack notch is and the rear is on the tires. I'm using a floor jack under the front crossmember to support the front clip. Will this be enough or should I brace it some more?

horse sence

15 Year Member

as many jack stands as possible,support it well. make sure you level it front,middle and rear. i always level at the lower radiator cross member ,down the rockers , the rockers through the car and across the trunk floors. .you will be crawling in and out of it a lot so the more support the better.

I got the box test fitted, fits pretty darn good if you ask me. I'm going to add more jackstands before I weld it in.

I did some measurements yesterday and the rockers are within 1/16" the same distance to the floor but the left front frame rail is 3/16" higher than the right. I measured from the floor to the bottom of the frame rail at the bumper mount. It was 7/16" higher but I jumped on the left bumper mount and that brought it down 1/4". Should I try to get the 3/16" out too before I weld in the torque box? I was thinking of getting my wife to sit on the front of the fender apron to push it down. I tried jacking up the frame rail where the floor pan would be but that didn't help.

horse sence

15 Year Member

put a level across the frame rails ,you may have to do it under the car .

try a level on the rockers as well through the doors that should show what is out

try a level on the rockers as well through the doors that should show what is out

I confirmed with a level that the driver's side is higher than the passenger's side at the bottom of the radiator support. I will get my wife to sit on the fender apron and see if that brings it level. She has always said that I don't include her when I'm working on the car, now is her chance

Has anyone ever tried filling the rocker with great stuff spray foam to keep water out? My rockers are rust free(about the only part of the car that is ) and I want to keep them that way.

) and I want to keep them that way.

) and I want to keep them that way.

) and I want to keep them that way.horse sence

15 Year Member

water needs to drain from the rockers. it goes down through the quarter windows and out through the rockers so you would not want to plug them up . rockers are galvinized inside and out so if you are not in an area that salts the roads you should not have any problems. you could spray primer in side for added protection. i use a garden sprayer .replace the wand with a rubber hose and and put the nozel in the hose and you can insert it into the rocker.

Rust Olium works realy well for this ,use the oil base for metal ,you may have to thin it to get it to spray

Rust Olium works realy well for this ,use the oil base for metal ,you may have to thin it to get it to spray

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 40

- Views

- 5K

- Replies

- 18

- Views

- 2K

- Replies

- 11

- Views

- 4K

- Replies

- 17

- Views

- 2K