- Jul 18, 2015

- 25

- 0

- 1

Hey guys, I own a modified 1992 5.0 Vortech Supercharged Notch.

I did not install the supercharger.

I'm having a squeaking belt issue.

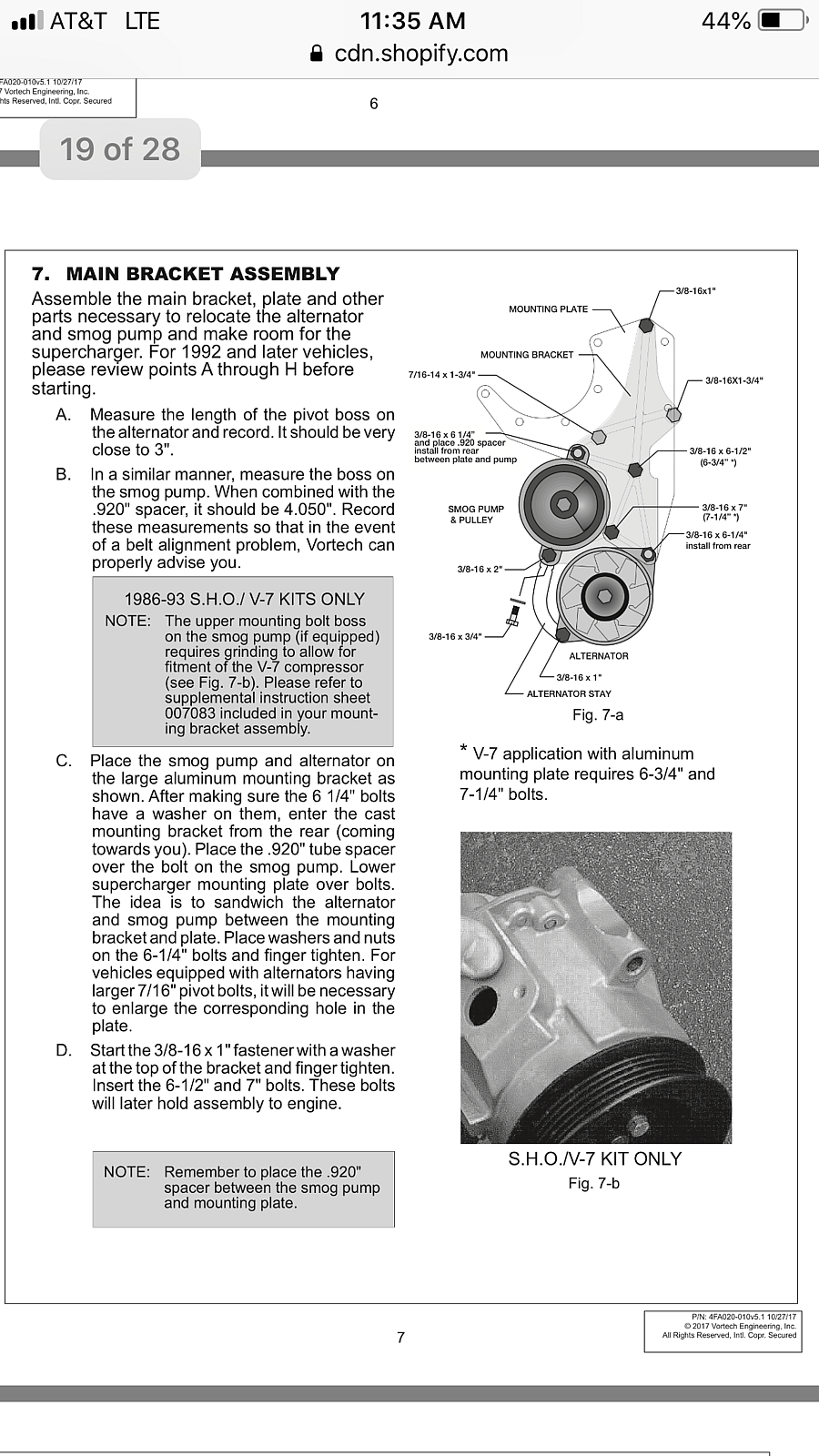

Under some investigation I found that the aftermarket 130a alternator is pushed forward / not aligned properly with the rest of the cars pulleys. And the belt is rubbing on the crank pully and smog delete pully.

I just replaced that smog pump pully because the bearing in it was going out and thought that might have been related to my squeaking belt.

After looking at the pictures what would you do to try and remedy this? I'm thinking taking it part and see if anything is bent/shimmed/loose?

Appreciate any input.

Thank you!

I did not install the supercharger.

I'm having a squeaking belt issue.

Under some investigation I found that the aftermarket 130a alternator is pushed forward / not aligned properly with the rest of the cars pulleys. And the belt is rubbing on the crank pully and smog delete pully.

I just replaced that smog pump pully because the bearing in it was going out and thought that might have been related to my squeaking belt.

After looking at the pictures what would you do to try and remedy this? I'm thinking taking it part and see if anything is bent/shimmed/loose?

Appreciate any input.

Thank you!