The clean up of the intake might have just caught a break! My dad spoke with a shop that does a lot of coating work for him, machine shop stuff. He forwarded them a bunch of detailed pictures of my parts and explained what I wanted done. They say that they can do the powder coating for 150-200. Much more reasonable than the guy Saturday that wanted up to 1k to do the same work. There is one catch. There is always a catch. They do not do the deep cleaning and say that the parts need to be completely clean of all oil and fluids inside and out. If they are not the oil can gas off in the curing process and mess up the coating. Now I just need to find a place to dip the parts. This is my first rodeo with powder coating, so feel free to chime in and educate me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Therapy Car-- Freshening Up the Lower Intake

- Thread starter Olivethefet

- Start date

-

Sponsors (?)

Monkeybutt2000

Mustang Master

Yeah. Honestly I didn't hate the guy for it. I just figured he really didn't want to do it. Now all I have to do is clean the stuff real good and I can get it all done for 200. I've never had anything powder coated. I've got no bench mark for what it should cost.

I found a shop today that can chem dip the parts. I've got to leave work tomorrow and go to a meeting in town, so I plan to drop everything off then. We'll see how it turns out. The service is cheap, so if it doesn't work as well as I hope I wont be out much money.

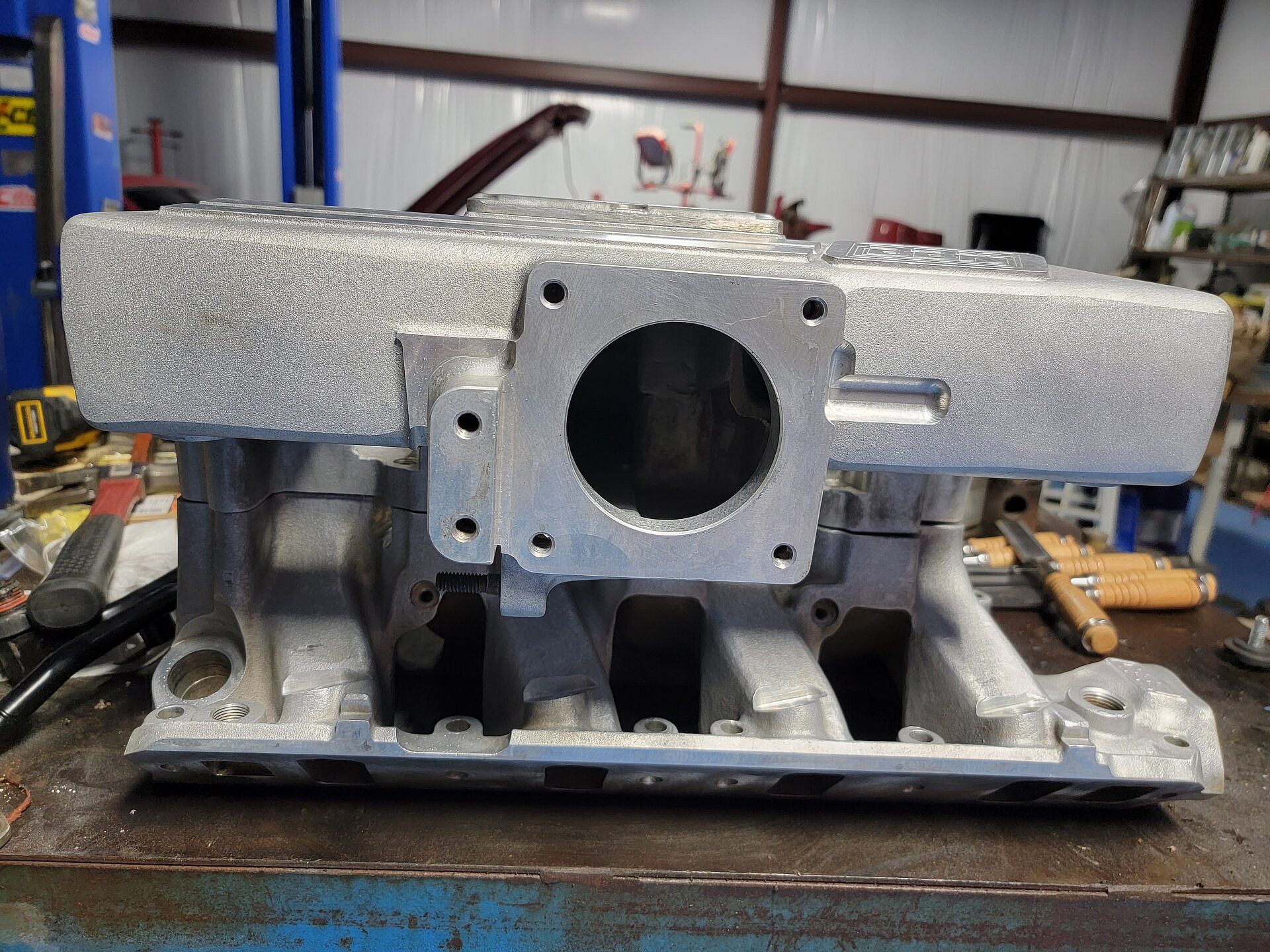

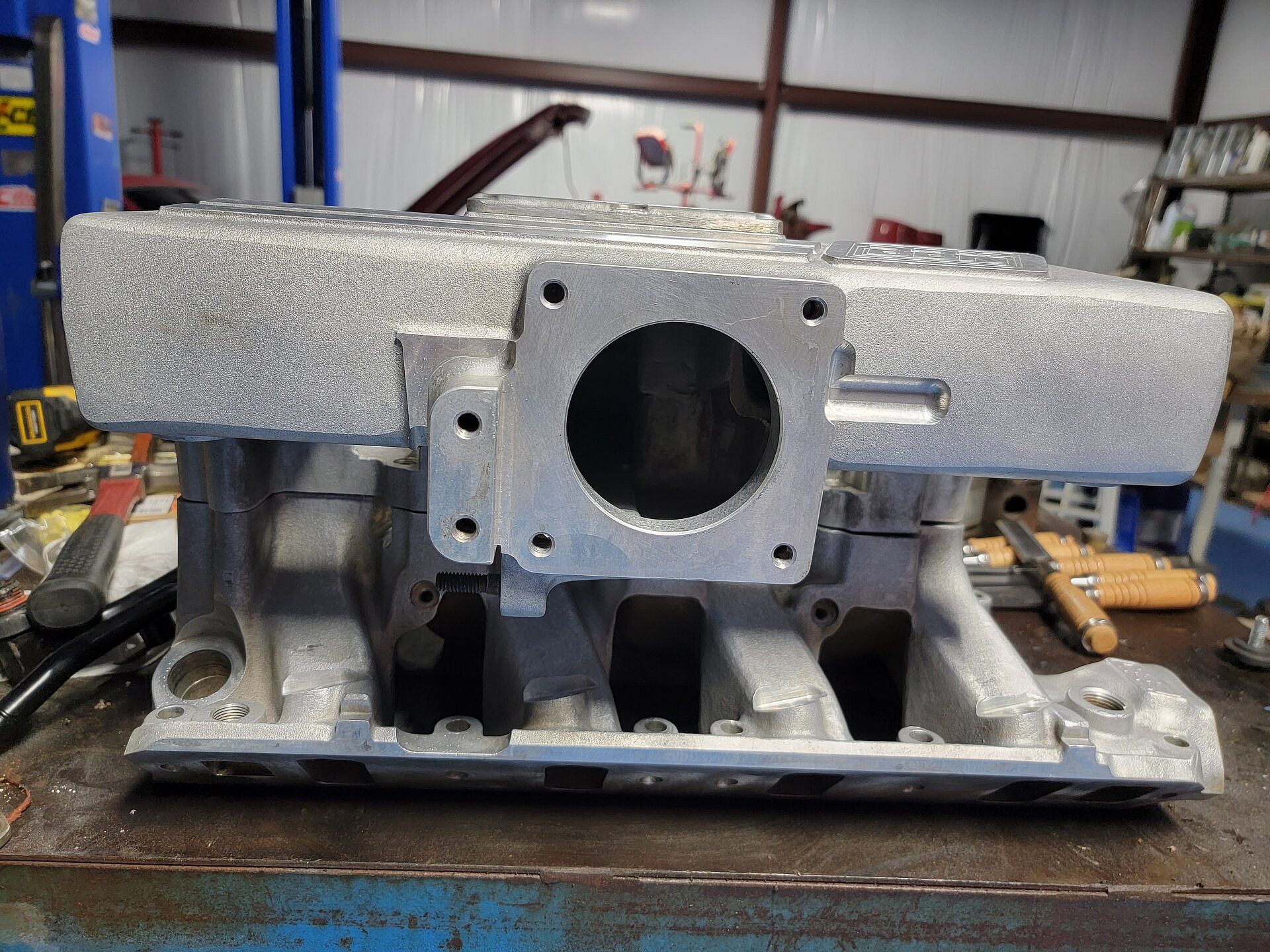

I finished stripping the few remaining components off of the upper and lower intake last night. I'll be dropping off to get dipped this afternoon. The first time I took the upper intake off 2+ years ago I found a couple of vacuum ports that had caps on them to block them off. The caps had rotted and were only acting as vac leaks. I put new caps on them and havent looked back. Last night I had to remove those new caps. They were cracked and probably leaking. Does anyone have a good solution for capping ports like these?

![20211116_205526[1].jpg 20211116_205526[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/20211116_205526-1-jpg.687212/)

![20211116_205526[1].jpg 20211116_205526[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/20211116_205526-1-jpg.687212/)

I used to coat all my own stuff at the house with an old oven.

I just blasted the parts clean and then gave them the dawn soap wash...

I would give them a heat cycle in the oven to cook off all the moisture and coat them not once did I have an issue

I just blasted the parts clean and then gave them the dawn soap wash...

I would give them a heat cycle in the oven to cook off all the moisture and coat them not once did I have an issue

pats91

15 Year Member

I would switch to vinyl caps like these:

I have had the same problems you had with parts store rubber caps. They are crap.

I have had the same problems you had with parts store rubber caps. They are crap.

there are really small plugs, think really small freeze plugs. Another option is to tap the hole for a screw in plug. Both require removing the nipple which can be a btch, if they can't be seen with intake installed I'd say fill 'em up with silicon gasket stuff or jbweld.I finished stripping the few remaining components off of the upper and lower intake last night. I'll be dropping off to get dipped this afternoon. The first time I took the upper intake off 2+ years ago I found a couple of vacuum ports that had caps on them to block them off. The caps had rotted and were only acting as vac leaks. I put new caps on them and havent looked back. Last night I had to remove those new caps. They were cracked and probably leaking. Does anyone have a good solution for capping ports like these?

![20211116_205526[1].jpg 20211116_205526[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/20211116_205526-1-jpg.687212/)

Monkeybutt2000

Mustang Master

Does anyone have a good solution for capping ports like these?

Do you need them? Will you in the future?

If not, remove them, drill/tap for an NPT plug and install plug and forget about it.

Make sure you flush the intake internally to get all particles out. In fact, after powdercoating, make sure you flush out the intake internally as well. I had a buddy who f'ed up a brand new engine because the powdercoater accidentally got a lot of powder in the intake and nobody ever checked to make sure it was clean.

No I dont need them. I think they are there to work with the emissions system Ford originally had on the car. The tap and plug method was mentioned earlier I believe and its a good idea. Thanks for pointing out the importance of making sure that there is not powder left in the intake before installing. That would be a major setback!Do you need them? Will you in the future?

I should have the parts back next week. I'll address the ports before I get it coated.

I actually thought about that. My wife would kill me if I used the oven in the house. In the future if I need/want to have a lot of stuff coated I will probably look into buying a cheap used oven just for powder coating. For this case I'll have less than $300 in cleaning and coating. By the time I source an oven and buy everything needed to get it set up I dont think I would really be saving much, if any, money on the job. Great idea though.I used to coat all my own stuff at the house with an old oven.

You get all set up for powder coating and you'll discover friends you never knew you had

I got my intake back today. Not much to show about the valve covers. They look about the same. They are just clean.

i’d go ahead and smack those freeze plugs out of the ends of that upper so as to be able to get everything clean after the P.C. put some new brass ones back in.

Next steps for the intake are to do a LOT of polishing of the shiny areas, get it taped off, get it to my dad for media blasting, then off to get powder coated. I'm sure there is more, but I'll figure that out as I go.

On a side note let me ask for the group opinion on air intakes. I currently have a BBK under hood intake. It's one of the chrome ones that is now discolored and pitted. It doesn't look very good and the support is a mangled mess that just bounces around against the inner finder. I'm going to do something to either fix it or replace it. My question is if you were upgrading/replacing the air intake would you rather go back to a stock air box with the silencer removed or get an aftermarket intake with the filter in the fender? My car still has the splash guard in the wheel well, and I'm not hung up on making it look stock. LMR seems to have everything in stock from 5.0 Resto to go back to a factory style air filter/intake. I might be able to source an OEM setup from the local mustang shop in town.

Making sure that everything is cleaned out after P.C. has been brought up before. I completely understand how powder in the intake during startup would wreck a motor. I would like a little clarification. When I spoke with the first guy about getting it coated he said that he would have to tape off or plug every hole in the intake to keep powder out of the intake. He even gave me a bunch of plugs to use in the injector holes and other holes in the upper and lower. He made it sound like keeping the powder on the outside was a big deal. He demonstrated how the powder gun worked. It was low pressure. Not like a media blaster or anything. Also, if powder got into the intake during the process would it not just melt and bond to the inside of the intake like the powder on the outside is going to do? It goes in an over at 450 for hours. I'm not questioning the logic to make sure there is no trash/grit getting into the motor. I'm just trying to understand the process better. Honestly I was looking forward to the freeze plugs being coated just like the rest of the intake. Shiny new brass ones would look good also though.i’d go ahead and smack those freeze plugs out of the ends of that upper so as to be able to get everything clean after the P.C. put some new brass ones back in.

On a side note let me ask for the group opinion on air intakes. I currently have a BBK under hood intake. It's one of the chrome ones that is now discolored and pitted. It doesn't look very good and the support is a mangled mess that just bounces around against the inner finder. I'm going to do something to either fix it or replace it. My question is if you were upgrading/replacing the air intake would you rather go back to a stock air box with the silencer removed or get an aftermarket intake with the filter in the fender? My car still has the splash guard in the wheel well, and I'm not hung up on making it look stock. LMR seems to have everything in stock from 5.0 Resto to go back to a factory style air filter/intake. I might be able to source an OEM setup from the local mustang shop in town.

Paint and reuse the chrome crap and use the stock style airbox with the stock hanger that bolts to the shock tower for support.

JMO

JMO

Willybill32

But at least it's tight!

I have the chrome MAC thru the fender air intake, and I keep thinking about reinstalling my stock air box instead. If I were in your shoes, I'd go with the stock air box.

Man, its been forever since the last time I had any news for this car. Things are just moving SLOW. It has taken forever to get the intake powder coated, but it has finally happened! A shop that my dads business does a lot of work with powder coated everything for me for a reasonable price. The parts are done. Now all I have to do is drive 5 hours to get them and settle up with my dad. LOL My son is graduating kindergarten in a few weeks. I'm hopping grandma will want to come down to be there. If she does she can bring the parts with here. I went with a simi gloss black. I wanted to go with flat but was warned that the flat sometimes has issues adhering to surfaces. It will be fine. I'd post pics but my dad only sent me a couple via text and they aren't much to look at. In the mean time I'll go ahead and order the gaskets everything I need to put everything back together. I'll be sure to make another update in 6 months or so!

Is that the cool looking BBK manifold?Mustang parts in the back of a Mustang. Looks better than they did. Let's see if they work.

Similar threads

- Replies

- 0

- Views

- 747

- Replies

- 17

- Views

- 2K

- Replies

- 45

- Views

- 3K

- Replies

- 12

- Views

- 739