Most of you guys probably know this stuff already, but I thought that I would share a few things I've learned while installing the torque box reinforcements. Maybe this will be helpful if someone stumbles across it in the future. Again, I have yet to see a good video that documents this process, and the kit comes with no instructions. So, installing the hardware for the lower torque box is pretty straight forward and there actually are decent videos out there that document that process well. I won't spend any time on that subject. The uppers is where you are left on your own to figure it out. If you work on stuff all the time or are just inclined to this kind of stuff it really isn't that big a deal.

The hardest part is just figuring out how to drill the holes and understanding what you are drilling through. What I found is that the inboard bolt hole can be drilled from under the car fairly easily. You have to remove the upper control arm to get where you need to drill. The outboard hole is a little trickier. In my case even though the drill bit was long it was still way to short to get to where it needed to be without the chuck hitting something and throwing it off. What I ended up doing was using the one bolt to bolt the plate in and then drilling from inside the car.

This is where understanding what you are drilling through helps a little. From under the car you can look up and in the upper torque box there are already two holes that basically line up with the holes in the bracket. That's great as it makes the process a lot easier. If you get a light and look up into the hole you'll see that there is another piece of metal in there that also has a hole in it. I did not realize this until I was basically done last night. The holes in this inner plate also line up with where the bolts pass. This is at least true with the passenger side of the car. I didn't look at the drivers side.

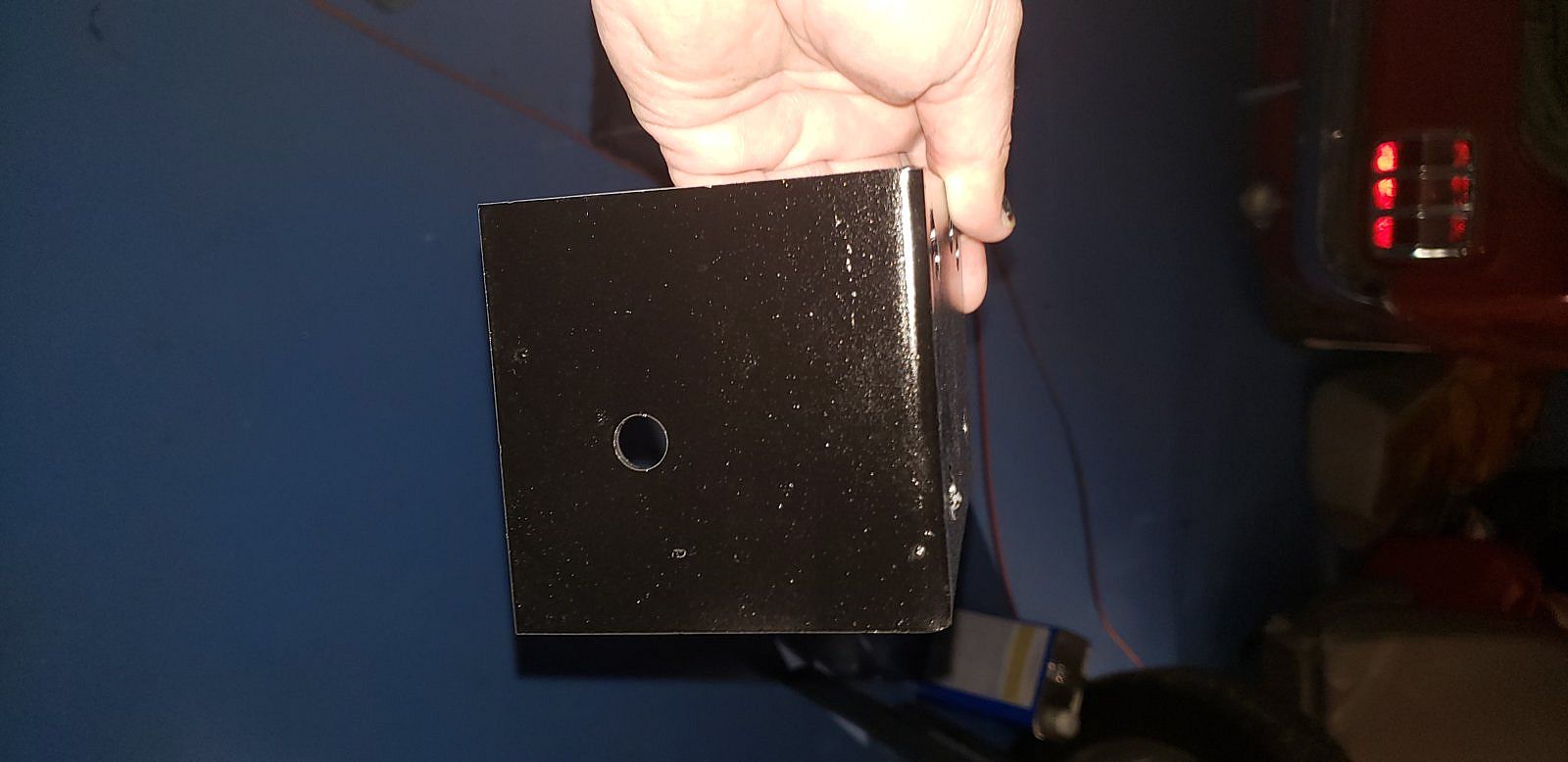

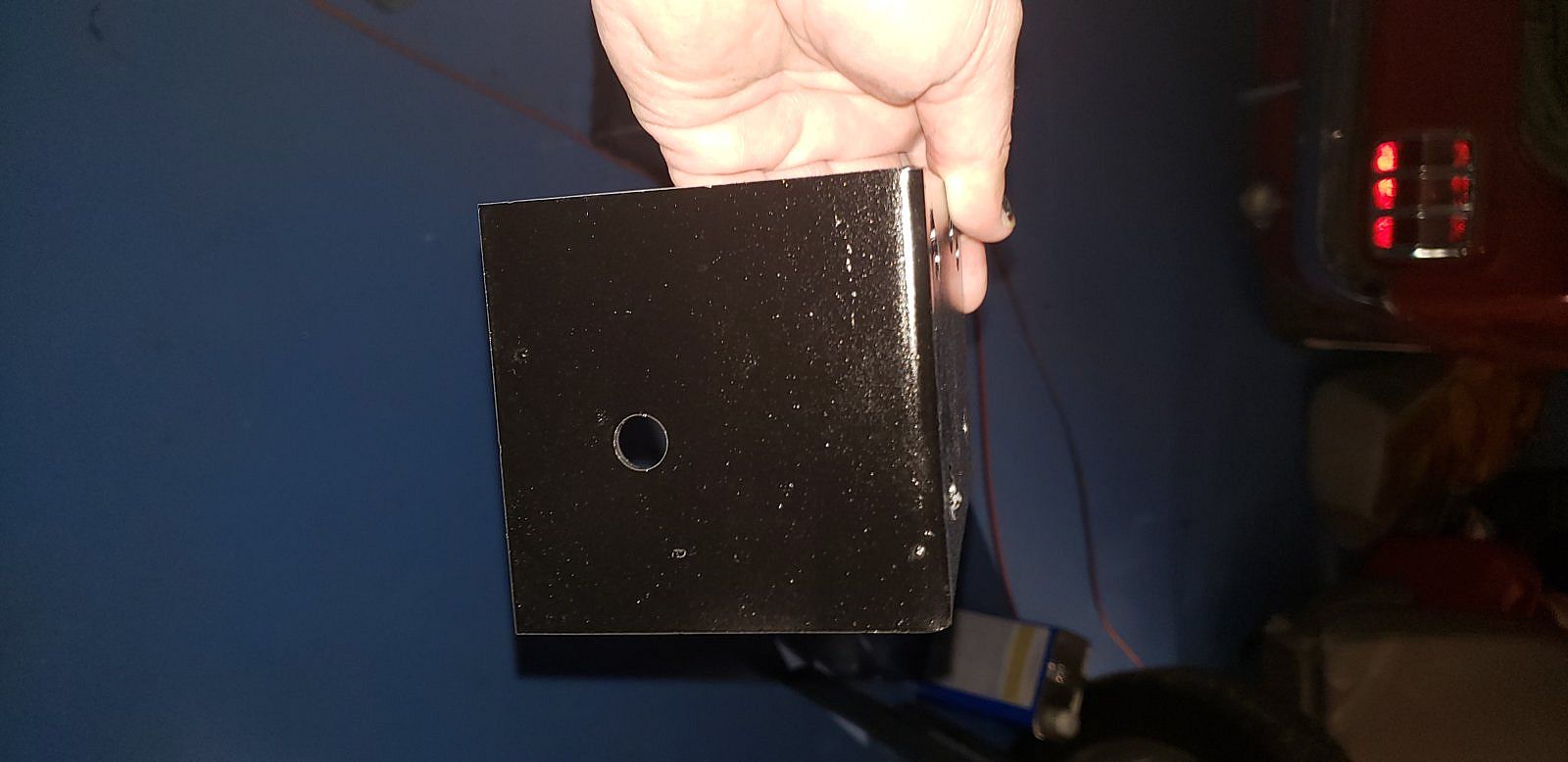

I got lucky with the inboard hole on both sides and didn't make a mess of things. The outboard hole ended up over sized, but that's OK, for me at least. Its under the plate, nobody is going to see it. You can see the inner plate in these two pictures.

Inboard:

The drill bit did not drill that inner hole and that is not the bottom of the torque box.

Outboard:

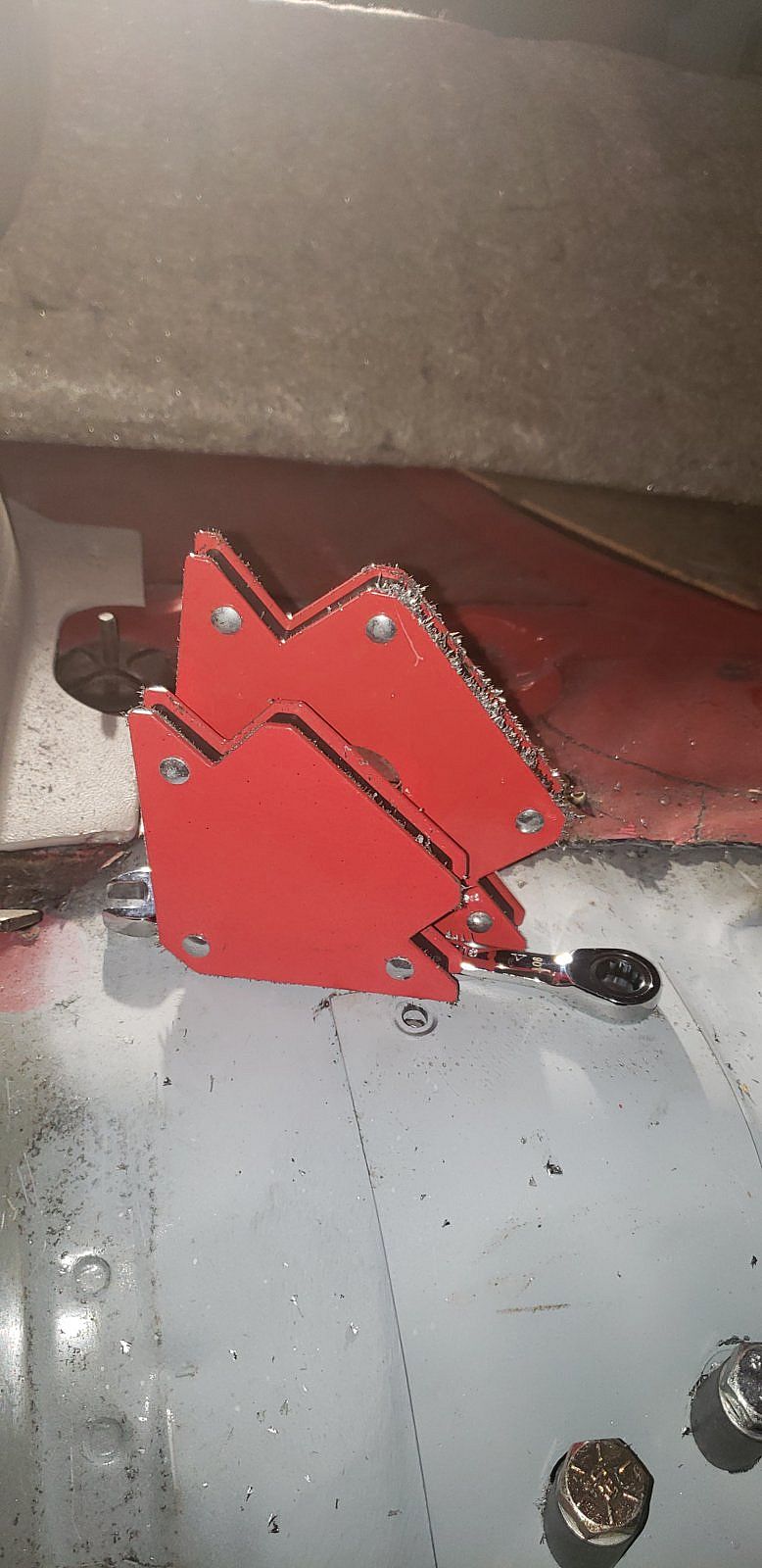

As seen in the first picture I traced the plate with a marker so I could grind the area in preparation for welding.

In the pic looking into the outboard hole you can see where I was trying to drill a hole in the wrong place. That's when I decided to take a look and see what was being so stubborn. I then saw that preexisting hole and decided to open up the outer hole so that I could drill straight into it. Once I did that the bolt dropped in and lined up pretty good. I don't think you can do this job without finessing a few places. Here is a pic of the plate and bolts in place.

As for the other two holes they just get drilled through from under the car. I didn't have any trouble with this on the other plate. Now there is a hump in the floor-pan right where the bottom of the plate is. I will probably trim about an inch off the plate just to get it to clear better. I also decided to add a couple of extra bolts on the top of the plate. They drill straight through from inside the car.

This job is not really that big a deal. It's just been way more of a PITA than I anticipated. Couple that with a lack of good instruction and it can be frustrating.

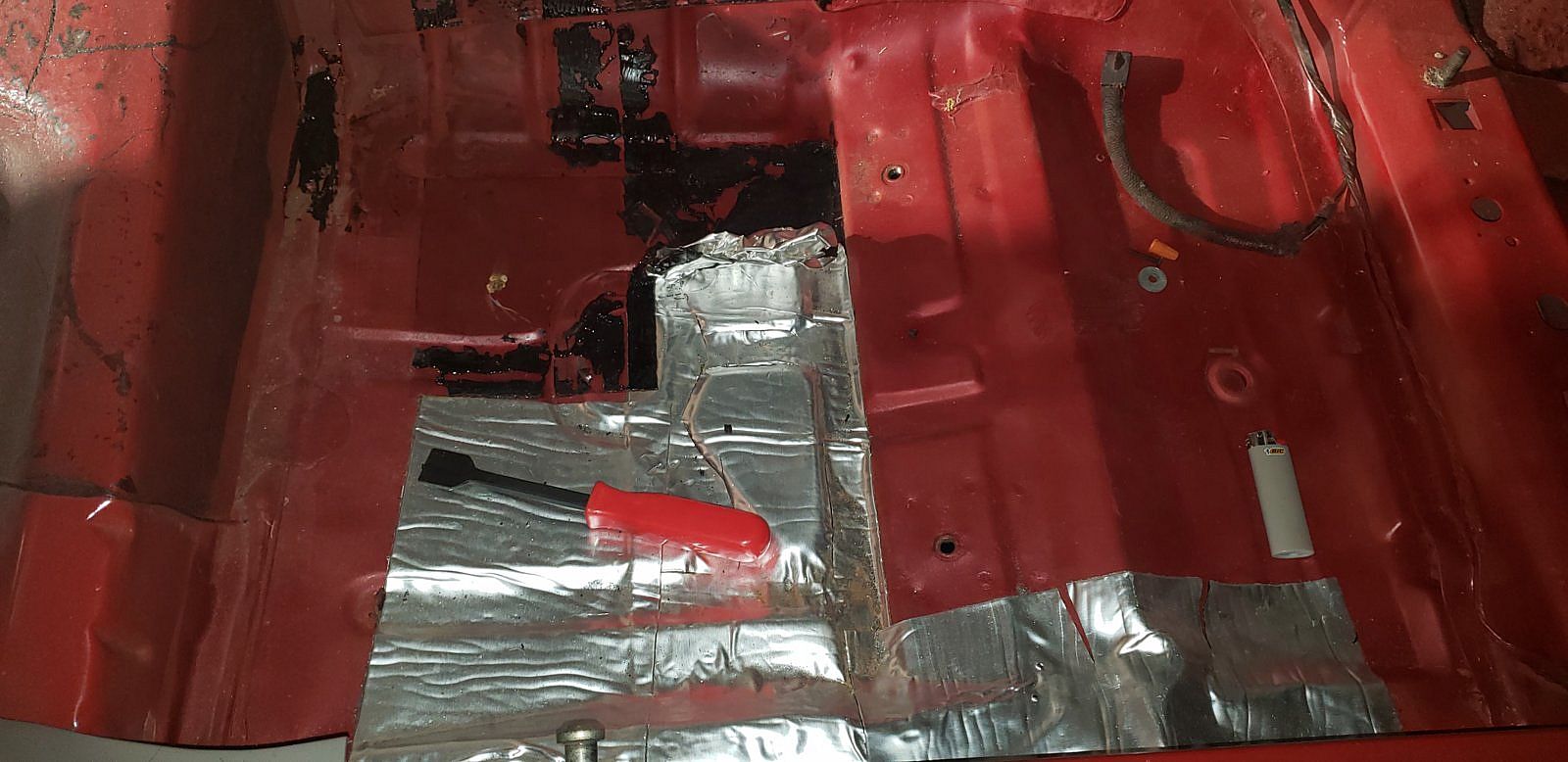

Here is a pic of the reinforcement that goes into the lower torque box. I pulled both sides back off so that I could paint them.

Ill get this back in tonight and this job will be mostly done. I still have to weld everything up. The best part is that I will at least be able to get the car off the lift.

The hardest part is just figuring out how to drill the holes and understanding what you are drilling through. What I found is that the inboard bolt hole can be drilled from under the car fairly easily. You have to remove the upper control arm to get where you need to drill. The outboard hole is a little trickier. In my case even though the drill bit was long it was still way to short to get to where it needed to be without the chuck hitting something and throwing it off. What I ended up doing was using the one bolt to bolt the plate in and then drilling from inside the car.

This is where understanding what you are drilling through helps a little. From under the car you can look up and in the upper torque box there are already two holes that basically line up with the holes in the bracket. That's great as it makes the process a lot easier. If you get a light and look up into the hole you'll see that there is another piece of metal in there that also has a hole in it. I did not realize this until I was basically done last night. The holes in this inner plate also line up with where the bolts pass. This is at least true with the passenger side of the car. I didn't look at the drivers side.

I got lucky with the inboard hole on both sides and didn't make a mess of things. The outboard hole ended up over sized, but that's OK, for me at least. Its under the plate, nobody is going to see it. You can see the inner plate in these two pictures.

Inboard:

The drill bit did not drill that inner hole and that is not the bottom of the torque box.

Outboard:

As seen in the first picture I traced the plate with a marker so I could grind the area in preparation for welding.

In the pic looking into the outboard hole you can see where I was trying to drill a hole in the wrong place. That's when I decided to take a look and see what was being so stubborn. I then saw that preexisting hole and decided to open up the outer hole so that I could drill straight into it. Once I did that the bolt dropped in and lined up pretty good. I don't think you can do this job without finessing a few places. Here is a pic of the plate and bolts in place.

As for the other two holes they just get drilled through from under the car. I didn't have any trouble with this on the other plate. Now there is a hump in the floor-pan right where the bottom of the plate is. I will probably trim about an inch off the plate just to get it to clear better. I also decided to add a couple of extra bolts on the top of the plate. They drill straight through from inside the car.

This job is not really that big a deal. It's just been way more of a PITA than I anticipated. Couple that with a lack of good instruction and it can be frustrating.

Here is a pic of the reinforcement that goes into the lower torque box. I pulled both sides back off so that I could paint them.

Ill get this back in tonight and this job will be mostly done. I still have to weld everything up. The best part is that I will at least be able to get the car off the lift.

Says it's made in the Russian Federation.

Says it's made in the Russian Federation.  All I need is to be accused of colluding with the Russians. We all know how that goes.

All I need is to be accused of colluding with the Russians. We all know how that goes.