Ok ,got a little dispute going on face book with an "engineer" he tells me that because i do not use a jig my conversion are junk  well ford did not use a jig to assemble our mustangs ,they used a skid ,the floor pan was bolted to the skid and off it went down the assembly line were it was turned into a mustang ,remember level is level and square is square no matter how you look at it

well ford did not use a jig to assemble our mustangs ,they used a skid ,the floor pan was bolted to the skid and off it went down the assembly line were it was turned into a mustang ,remember level is level and square is square no matter how you look at it

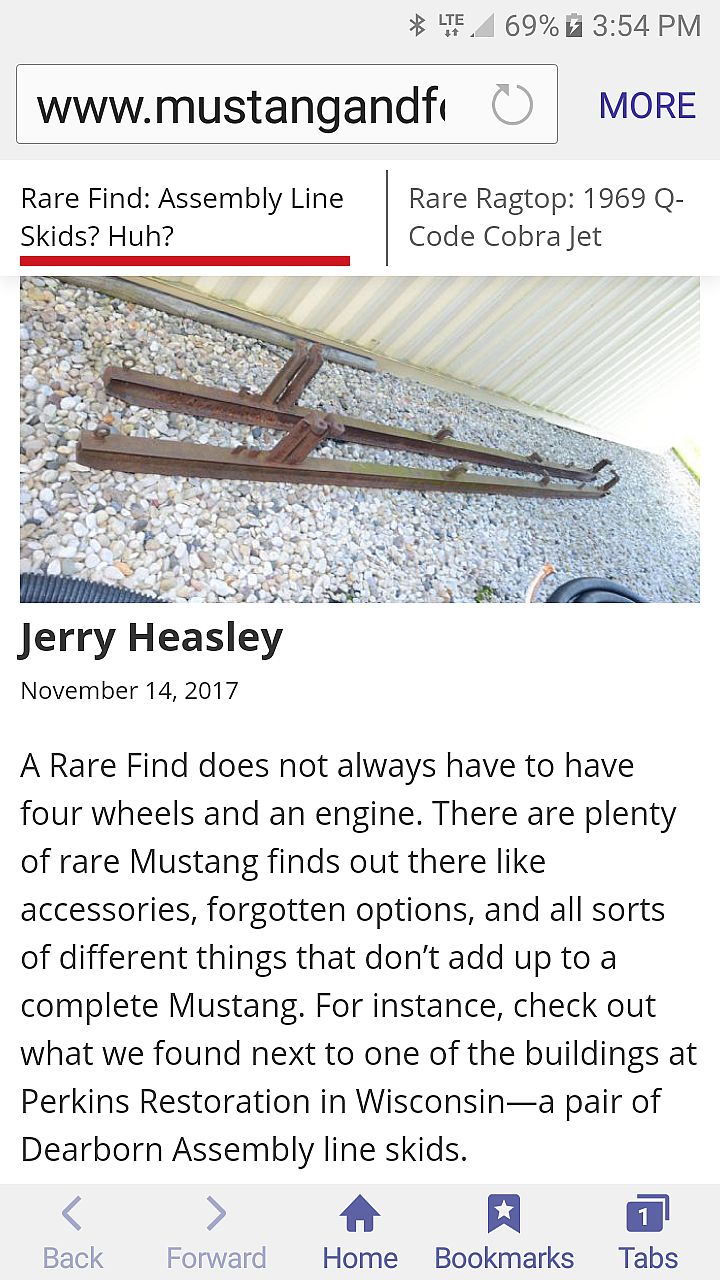

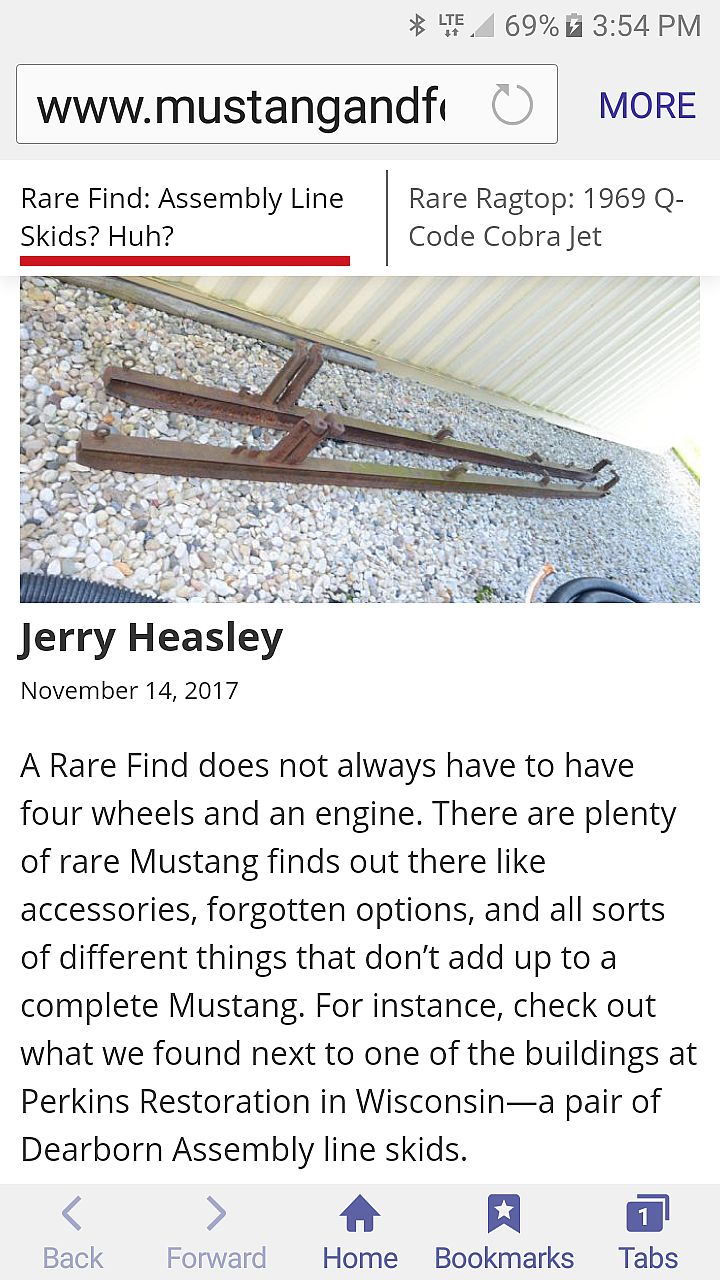

as you can see a skid is two seperate sides ,a jig is a welded fixture . The body panels were aligned through holes in each panel ,look at your car and you will see these alignment holes. As long as you are square and level and go by fords measurements you are golden ,i use a self leveling laser as the datum ,that is where all measurements for the sub structure come from ,if you are doing a conversion you will already have a finishex sub structure to start from . Everything else you should have a car to get the upper structure measurements from ,look at the measurement car as a blue print and a measure ment from it is the same measurement on your conversion.

as you can see a skid is two seperate sides ,a jig is a welded fixture . The body panels were aligned through holes in each panel ,look at your car and you will see these alignment holes. As long as you are square and level and go by fords measurements you are golden ,i use a self leveling laser as the datum ,that is where all measurements for the sub structure come from ,if you are doing a conversion you will already have a finishex sub structure to start from . Everything else you should have a car to get the upper structure measurements from ,look at the measurement car as a blue print and a measure ment from it is the same measurement on your conversion.

Now we get into welding ,i am told that a mig welder is not the same as a spot welder ...he is a metalergest and a mig welder will crack at the welds ...here is a screen shot from BAR of California and you can see a mig is pretty much standard in the industry

there is a lot of so called experts out there so dont let these guys talk you out of a conversion ,if it is what you want to do ...do it.

there is a lot of so called experts out there so dont let these guys talk you out of a conversion ,if it is what you want to do ...do it.

well ford did not use a jig to assemble our mustangs ,they used a skid ,the floor pan was bolted to the skid and off it went down the assembly line were it was turned into a mustang ,remember level is level and square is square no matter how you look at it

well ford did not use a jig to assemble our mustangs ,they used a skid ,the floor pan was bolted to the skid and off it went down the assembly line were it was turned into a mustang ,remember level is level and square is square no matter how you look at it

Now we get into welding ,i am told that a mig welder is not the same as a spot welder ...he is a metalergest and a mig welder will crack at the welds ...here is a screen shot from BAR of California and you can see a mig is pretty much standard in the industry