Hey Mike, I looked at your picture of the hood. It looks like something was set on it or some fluid was on it.

Do you know what caused the mark?

Do you know what caused the mark?

Nah, admittedly he took me to the airport within 45 minutes after I shot it.....soooo......ok, you may be right......He leaned it aginst something before it dried well enough.

Nah, admittedly he took me to the airport within 45 minutes after I shot it.....soooo......ok, you may be right......

Running true to form...

Clearly, there is a big difference between the Hot Rod black that summit sells, and the PPG brand that is pictured above..

Painting the hood was literally "point and shoot". This pic taken immediately after putting the gun down, long before the paint started to flatten.

As to be expected, painting anything black will exaggerate flaws, and defects, and I have them, but I was just happy that the paint laid down w/o any of the striping, orange peel, and dry spray issues I had the last time I was trying to paint something.

After a couple of hours, I thought it was dry enough to start reassembly, but as usual, what I think, and what is reality are usually far apart.

Taken right before I fcked it up. Everything drying and laying out nicely.

In order to force myself to leave it alone, I decided to wash the car..that took another hour.

Then I started putting it together.

Put the rear vents on....

No problem.

Put the aerocatch hood pins on.

No problem.

I leaned the hood against the wall so that I could put the heat shield insulation underneath..thinking that I had sufficiently padded the orange part ( which was never repainted, and dry since Dave painted it)

And put that sht on the underside.

Then checked the hood to find that the padding had slipped,..and was making contact with the freshly painted black part....

And left a significant impression.

The tires get here today..As much as I want to leave ride height alone, and just let the taller tire make up the rake angle I’m wanting, the fact of the matter is they are too close to making contact with the quarter. If I have to raise the rear for any reason, I’m gonna have to probably alter the front a little too.

The car is actually too low in reality,..I can’t even get the thing out of the driveway w/o coming and going nose first. The oil pan is scary low...and if I don’t raise the front after putting that taller tire on back, it’ll get even worse. We’ll see what it looks like soon enough.

Seems that going to bed at 9 puts me in a “ auto-wake” mode riiight around 4:30-4:45 AM...that’s almost 8 hours, and now that fckin daylight savings time has been changed back, the sun peeks in at 5. Once that happens...i’m doomed. I never go back to sleep. So....here I am..wide the hell awake at 6. I could go to bed later, and get up at later, but what difference would that make anyway?

The 3AMD has changed with the clock too, coincidentally.....Let there be something that bugs me, and now he‘s there at 4AM...freakin dick.

Today, of course we talked about the hood...He wanted to know whether or not I’m gonna repaint it.

I cant “ rub it out” that’s for sure..I don’t know if I can spot it in,..If I was Dave, I’m sure it could be done..But I’m not Dave.

@Davedacarpainter ?

The car is now a pain in the dick to cold start,...requiring several restarts after it catches and sputters..I’ll also tap Steve this morning. @a91what.

The screech that I thought was gone is still alive and well...As I drill down trying to determine where it’s coming from, I think it only starts happening in 3rd gear..That’ll be a Sunday test to confirm that for sure, but I’m about 90% sure that’s the deal. And why it’s only happening in 3rd is beyond me.( maybe in 4th too, but to confirm that at that speed needs some serious deserted road). In hindsight, the old BOV, damaged as it was wasnt to blame. You’d think if I had a boost leak, the noise would be there regardless of the gear. But once it starts, it stays the same pitch/ level and will stop immediately if I lift. So it’s not speed related either. I only know that I want the damn thing gone.

Call Dave...but you’re too late to do anything other than tell me that I’m gonna have to take the remaining paint, and repaint that bitch.Sorry Mike, I’ve been a little busy as of late and haven’t been around enough.

Want me to call? Or am I too late to help?

It’s getting repainted today after it gets a little later this morning. I spoke with Dave last night, and the fix is a total repaint. Fortunately, it seems much easier than it was the last time i tried it, and excepting the bleed through and where i managed to fck it up,..it would’ve been a keeper. When it warms up in about 2 hours, i’ll be sanding again.So where are the pictures of the repainted/repainted hood? Or is it repainted/repainted/repainted? I loose track.

I know you can't sit there knowing that fcked up paint is sitting in the basement just waiting for a redo.

)..The problem is, that there isn’t any down angle adjustment in this TA..I’d have to cut it apart, and reweld it.

)..The problem is, that there isn’t any down angle adjustment in this TA..I’d have to cut it apart, and reweld it.

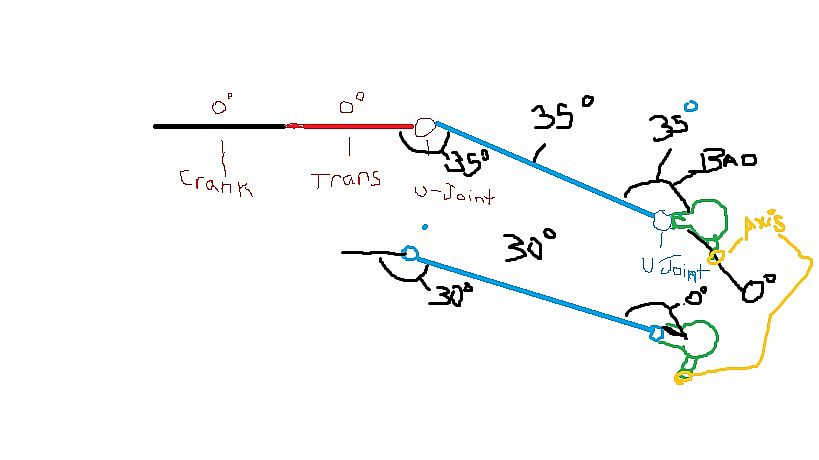

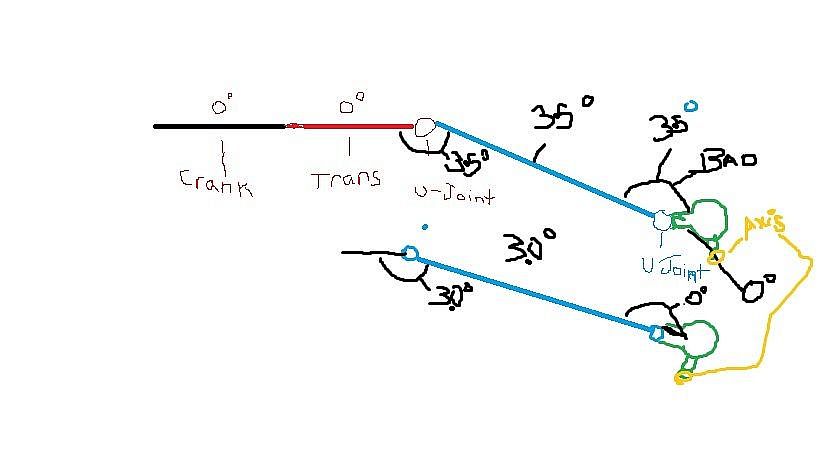

Woz Not My Diagram. It should have had decimals in it. It can be decimated by traditional Roman "stoning, clubbing, or stabbing". But in this case, I've added a Peaceful Latin~ Indo European Decimal Point.I always thought you put the pinion down about 2-4 degrees less than the driveline, so under acceleration was the pinion rotates up, it come in line and doesn't go above the driveshaft angle. I have no idea what dean drew....if your pinion is 30 degrees you need about 7 cv joints in that beach. I guess that's NZ for 3.0 or 3.5. I need a universal translator!

I suspected that torque arm wasn't ok with the TooJZ hit full song with some sticky tars on it.

But what do I know..I have a car with leaf springs.

I always thought you put the pinion down about 2-4 degrees less than the driveline, so under acceleration was the pinion rotates up, it come in line and doesn't go above the driveshaft angle. I have no idea what dean drew....if your pinion is 30 degrees you need about 7 cv joints in that beach. I guess that's NZ for 3.0 or 3.5. I need a universal translator!

I suspected that torque arm wasn't ok with the TooJZ hit full song with some sticky tars on it.

But what do I know..I have a car with leaf springs.