I should have been clearer, I meant getting new rings?I wont know that till I get the pistons out...and......Yes,...the garage is now truly "bloodied".

All I know so far is that I should use moly rings with my little engine.

I should have been clearer, I meant getting new rings?I wont know that till I get the pistons out...and......Yes,...the garage is now truly "bloodied".

Dave, Dave, Dave.......You were at my house...I watched you.I should have been clearer, I meant getting new rings?

All I know so far is that I should use moly rings with my little engine.

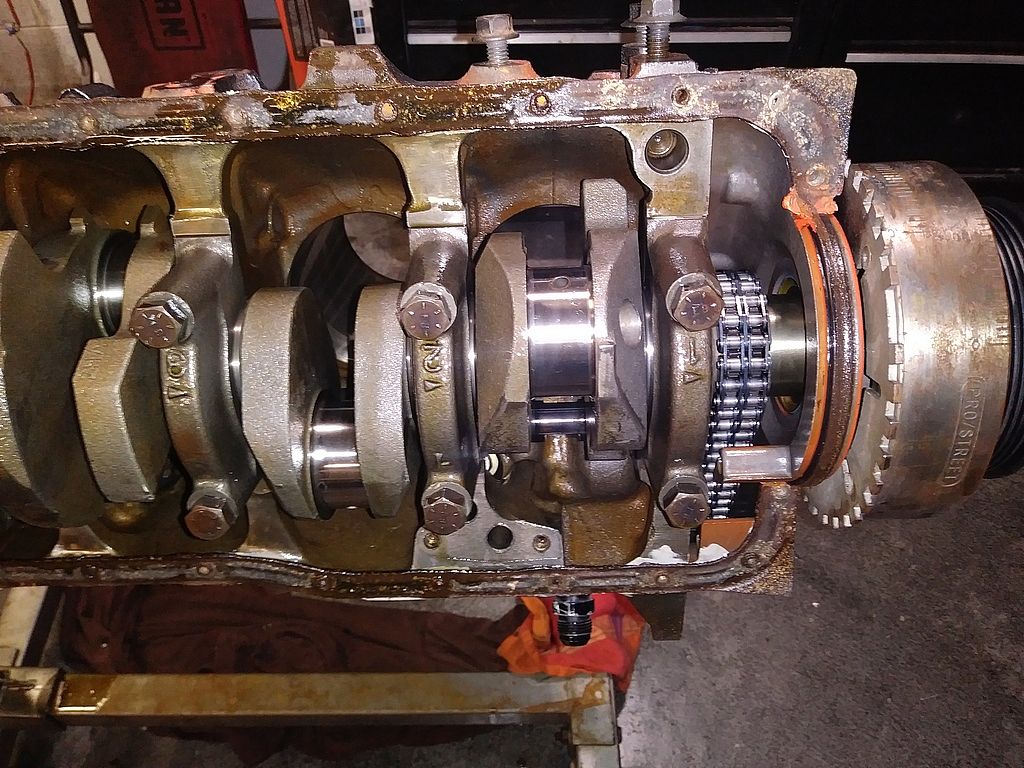

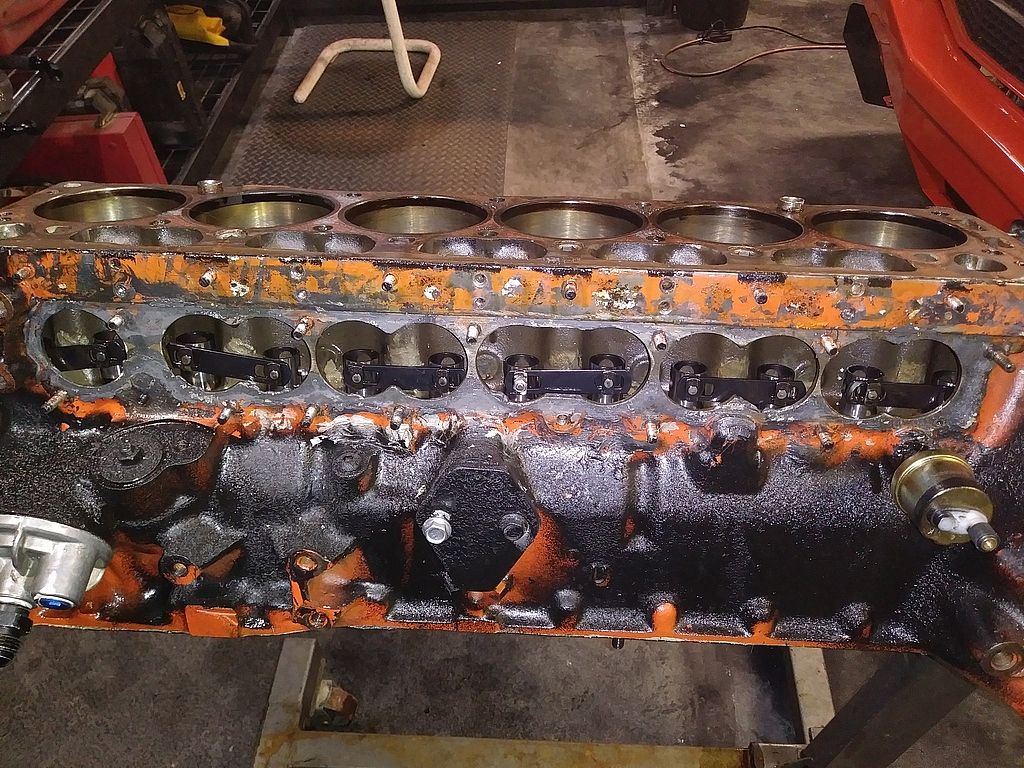

3.5 months past the day of the surgery. I'm getting better, but I'd say that I'm only at 65% of full usage. The left knee won't bend anywhere near what the right one will. Both stiffen if I sit too long, both swell if I stand too long.I'm reading fast before having to go, and maybe I missed this. You're what, around 2 months after the 'procedure'. How are the knees holding up buddy? I am sure you had to up-down a time or two to get that iron slug out. It looks to me like you have the chance to improve the fit and finish of things. I have an out door bar top and grill center I built a couple of years ago, that I know if I did today, would be SOOO much better. It's like as soon as I get something done, I see all the little problems and know how I could do it better the next time. I think must of us are that way on our cars. We either want to start fixing what we fixed or we sell it and start over!

Check your axial or gap clearance.

Do you see even shadow along the barrel face of the ring all the way around? There should be a dark shadow about half the ring where it is making contact with the cylinder. It should be consistent all the way around the ring.

Again, this is just to reinforce the side of the block where I had to grind the lifter galley open big enough to get the pushrods to clear..so it really isn't that big a deal. But I could not get the plate, or the intake manifold off w/o having to beat a screwdriver between the intake and the head, and the plate and the block where it actually damaged the aluminum, and broke the epoxy seal...

I haven't looked closely, but I'm gonna say no. Ill ck when I get home later.No the up and down clearance. Do the ring lands show any wear?

Again, the engine is healthy. The tune was right for probably upwards of 15 psi after the water meth got added.So the only thing that was really "wrong" with the engine was the ring gaps and not so much the rings themselves? So are we thinking it could have survived more boost if you wouldn't have decided to do a refresh?

Well, better safe than sorry.