Backfiring out the intake is either a valve stuck open or a lean mixture or spark plug wire(s) connected to the wrong cylinder(s). Check compression on all cylinders and then look for vacuum hoses loose, cracked, or misconnected. Check the line for the vapor recirculation system – it is easy to knock loose and not see it when you connect the air pump plumbing. If the vacuum line for the EGR valve and the air pump are cross connected, some very strange things can happen. Check the mass air flow electrical connection and see that it is tight, the same goes for the fuel injection wiring harness connectors up on top of the manifold near the firewall.

Sticking valves: If a intake valve is bent, has a bad spring or is misadjusted, the engine will sometimes backfire through the intake. Use a vacuum gauge connected to any convenient spot on the intake manifold. Run the engine at 1000 RPM & look for 18-21 inches of vacuum with a steady needle. A problem intake valve will make the vacuum gauge needle sweep 5-10 inches.

Lean fuel mixture breaks out into several sub categories:

A.). Vacuum leaks

B.) Air entering the intake without passing through the MAF on Mass Air cars (89-95 models).

C.) Failure of the MAF, BAP/MAP (Baro or Manifold Air Pressure, same sensor, different name), ACT (air charge temp), or ECT (engine coolant temp). These should set a code in the computer.

D.) O2 sensor problems: one or both O2 sensors with low output or bad O2 sensor heater ground. This should set codes 41/91. The O2 sensor heater ground is an Orange wire in the engine mounted fuel injector harness. Ground it to the back of the head or intake manifold.

E.) Leaking exhaust gases from EGR valve at WOT or EGR opening when it should not be open.

F.) Poor fuel delivery due to bad fuel pump, clogged filter or bad fuel pump wiring. Look for low pressure or fluctuating pressure. Standard injector pressure is 39 PSI at idle, with the vacuum line disconnected from the regulator and capped.

G.) Clogged fuel injectors.- see the cylinder balance test below

H.) Fuel injector wiring problems causing injector not to deliver rated flow (dirty or stuck shut injectors).

I.) Computer problems: (computer problems are not common like sensor problems)

J.). ROM has bad data in fuel or timing table. This should also set a code in the computer.

K.) Failure of one or more of the computer's driver transistors for the fuel injectors. No code set on this one. Use a noid test light to test the injector wiring & injector drivers,

L.) MAF calibration off or mismatched to injectors.

M.) ACT or ECT bad. Sometimes the sensors will be off calibration, but not bad enough to set a code. If they falsely read too high a temp, the engine will back off fuel delivery.

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

Vacuum leak due to slipped lower intake manifold gasket...

Ask Nicoleb3x3 about the intake gasket that slipped out of place and caused idle and vacuum leak problems that could not be seen or found by external examination. I don't care what you spray with, you won't find the leak when it is sucking air from the lifter valley. It simply isn't possible to spray anything in there with the lower manifold bolted in place.

Dump the codes: Codes may be present even if the Check Engine Light (CEL) isn't on.

Dumping the computer diagnostic codes on 86-95 Mustangs

Revised 26-July-2011. Added need to make sure the clutch is pressed when dumping codes.

Codes may be present even if the check engine light hasn’t come on, so be sure to check for them.

Here's the way to dump the computer codes with only a jumper wire or paper clip and the check engine light, or test light or voltmeter. I’ve used it for years, and it works great. You watch the flashing test lamp or Check Engine Light and count the flashes.

Post the codes you get and I will post 86-93 model 5.0 Mustang specific code definitions and fixes. I do not have a complete listing for 94-95 models 5.0 Mustangs at this time.

Be sure to turn off the A/C, and put the transmission in neutral when dumping the codes. On a manual transmission car, be sure to press the clutch to the floor.

Fail to do this and you will generate a code 67 and not be able to dump the Engine Running codes.

Foxbody Diagnostic connector

Foxbody Diagnostic connector close up view

If your car is an 86-88 stang, you'll have to use the test lamp or voltmeter method. There is no functional check engine light on the 86-88's except possibly the Cali Mass Air cars.

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

89 through 95 cars have a working Check Engine light. Watch it instead of using a test lamp.

The STI has a gray connector shell and a white/red wire. It comes from the same bundle of wires as the self test connector.

WARNING!!! There is a single dark brown connector with a black/orange wire. It is the 12 volt power to the under the hood light. Do not jumper it to the computer test connector. If you do, you will damage the computer.

What to expect:

You should get a code 11 (two single flashes in succession). This says that the computer's internal workings are OK, and that the wiring to put the computer into diagnostic mode is good. No code 11 and you have some wiring problems.

This is crucial: the same wire that provides the ground to dump the codes provides signal ground for the TPS, EGR, ACT and Map/Baro sensors. If it fails, you will have poor performance, economy and drivability problems

Some codes have different answers if the engine is running from the answers that it has when the engine isn't running. It helps a lot to know if you had the engine running when you ran the test.

Dumping the Engine Running codes: The procedure is the same, you start the engine with the test jumper in place. Be sure the A/C is off, and clutch (if present) is pressed to the floor, and the transmission is in neutral. You'll get an 11, then a 4 and the engine will speed up to do the EGR test. After the engine speed decreases back to idle, it will dump the engine running codes.

Trouble codes are either 2 digit or 3 digit, there are no cars that use both 2 digit codes and 3 digit codes.

Your 86-88 5.0 won't have a working Check Engine Light, so you'll need a test light.

See AutoZone Part Number: 25886 , $10

Alternate methods:

For those who are intimidated by all the wires & connections, see

Actron® for what a typical hand scanner looks like. Normal retail price is about $30 or so at AutoZone or Wal-Mart.

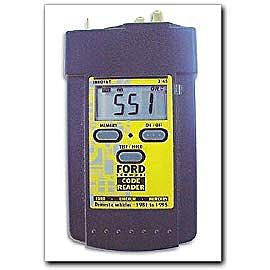

Reader/dp/B000EW0KHW Equus - Digital Ford Code Reader 3145.

Or for a nicer scanner see

www.midwayautosupply.com/Equus-Digital-Ford-Code-It has a 3 digit LCD display so that you don’t have to count flashes or beeps.. Cost is $22-$36.

Order it at Walmart for a better price and free shipping

Cylinder balance test

If you have idle or IAC/IAB problems and the engine will not idle on its own without mechanically adjusting the base idle speed above 625-750 RPM, this test will fail with random cylinders pointed out every time it runs. The IAC/IAB

must be capable of controlling the engine speed to run in the 1300-1500 RPM range. Playing with the base idle speed by adjusting it upwards will not work, the computer has to be able to control the engine speed using the IAC/IAB.

Warm the car's engine up to normal operating temperature. With the test jumper in test position, start the engine and let it stabilize. It should flash a 10 and then a 4 and maybe an 11. If no 11, then there are other codes that will be dumped.

One of the first tests it does is to open the EGR all the way, this will cause the engine to stumble and almost die. If the engine dies here then you have EGR problems.

To start the cylinder balance test, briefly floor the accelerator past 2500 RPM and let off the accelerator. The engine will stabilize at about 1300-1450 RPM and the cut off the fuel injectors one at a time. The engine speed will drop briefly and the computer will turn the fuel injector for the cylinder under test back on. Then it starts the process for the next cylinder. When it has sequenced through all 8 injectors, it will flash 9 for everything OK, or the number of the failing cylinder such as 2 for cylinder #2. Quickly pressing the throttle again up to 2500 RPM’s will cause the test to re-run with smaller qualifying figures.

Do it a third time, and if the same cylinder shows up, the cylinder is weak and isn’t putting out power like it should. See the Chilton’s Shop manual for the complete test procedure

See

View: https://www.youtube.com/watch?v=HDXrkKS4jTE

for a visual tour through the process. There is no voice narration so you have to listen carefully for the engine sounds. I posted the link for the benefit of Stangnet members who had questions about how to do a cylinder balance test. I do not own that video and I am not the creator.

and I will have to do the o2 sensors as well... Hopefully I'll be able to report back in a few hours, I know it should be less, but this is the most extensive engine work I have ever done!

and I will have to do the o2 sensors as well... Hopefully I'll be able to report back in a few hours, I know it should be less, but this is the most extensive engine work I have ever done!