Finding vacuum leaks

Revised 04-Aug-2011 to add pintle cap, PCV grommet & power brake check valve grommet to checklist.

There is no easy way to find vacuum leaks. It is a time consuming job that requires close inspection of each and every hose and connection.

Small vacuum leaks may not show much change using a vacuum gauge. The range of "good readings" varies so much from engine to engine that it may be difficult to detect small leaks. The engine in my first Mustang pulled about 16.5" of vacuum at 650-725 RPM, which I consider rather low. It was a mass market remanufactured rebuild, so no telling what kind of camshaft it had. Average readings seem to run 16"-18" inches at idle and 18"-21" at 1000 RPM. The only sure comparison is a reading taken when your car was performing at its best through all the RPM ranges and what it is doing now. Use one of the spare ports on the vacuum tree that is mounted on the firewall near the windshield wiper motor.

Use a squirt can of motor oil to squirt around the mating surfaces of the manifold & TB. The oil will be sucked into the leaking area and the engine will change speed.

Avoid using flammable substitutes for the oil such as starting fluid, propane or throttle body cleaner. Fire is an excellent hair removal agent, and no eyebrows is not cool...

The vacuum line plumbing is old and brittle on many of these cars, so replacing the lines with new hose is a good plan. The common 1/8” and ¼” vacuum hose works well and isn’t expensive.

The PCV grommet and the power brake booster check valve grommet are two places that often get overlooked when checking for vacuum leaks. The rubber grommets get hard and lose their ability to seal properly. The PVC grommet is difficult to see if it is correctly seated and fitting snugly.

Fuel injector O rings can get old and hard. When they do, they are prone to leaking once the engine warms up. This can be difficult to troubleshoot, since it is almost impossible to get to the injectors to squirt oil into the fuel injector mounting bosses. If the plastic caps on the fuel injectors (pintle caps) are missing, the O rings will slide off the injectors and fall into the intake manifold.

Fuel injector seal kits with 2 O rings and a pintle cap (Borg-Warner P/N 274081) are available at Pep Boys auto parts. Cost is about $3-$4 per kit. The following are listed at the Borg-Warner site (

BWD - Home ) as being resellers of Borg-Warner parts:

Parts Plus – Premium Auto Parts & Accessories or

Auto Value or

Pep Boys | Tires | Auto Repair & Service | Car Parts | Car Accessories or

Federated Auto Parts

Most of the links above have store locators for find a store in your area.

Use motor oil on the O rings when you re-assemble them & everything will slide into place. The gasoline will wash away any excess oil that gets in the wrong places and it will burn up in the combustion chamber. Heat the pintle caps in boiling water to soften them to make them easier to install.

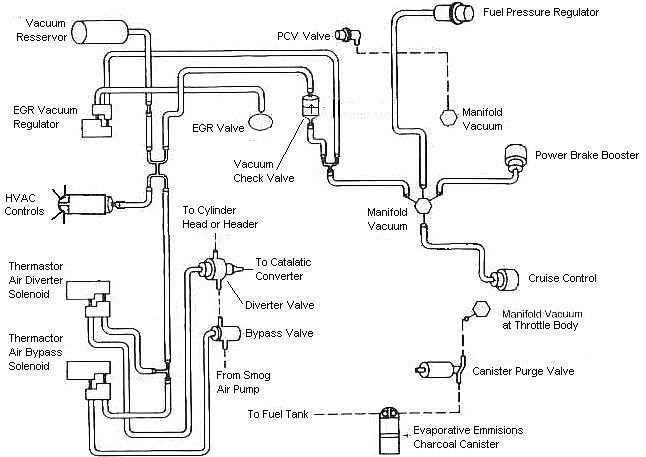

Diagram courtesy of Tmoss & Stang&2birds

Vacuum leak due to slipped lower intake manifold gasket...

Ask Nicoleb3x3 about the intake gasket that slipped out of place and caused idle and vacuum leak problems that could not be seen or found by external examination. I don't care what you spray with, you won't find the leak when it is sucking air from the lifter valley. It simply isn't possible to spray anything in there with the lower manifold bolted in place.

Determining if you have a leak due to a slipped intake gasket as shown above. This test is only good if you can get the engine to run somewhere in the 1000-1700 RPM range

If your valve cover oil filler & PVC systems are still in the original configuration, try this:

Cap or plug the hose from the intake manifold to the PVC valve with a bolt.

Cap or plug the PVC valve with a piece of hose with a plug or bolt in it.

At that point the only vent for the crankcase is the tube from the oil filler neck to the throttle body.

Disconnect the tube that runs from the oil filler neck to the throttle body. Make sure the oil filler cap is on securely. Start the engine and put your thumb over the end of the tube that comes from the oil filler cap. If you feel suction, there is a leak. Another thing to do is to extend the tubing from the filler neck so that there is enough to stick the end in a jar or cup filled with motor oil. If it sucks up the oil, you definitely have a leak at the underside of intake manifold.

This isn't necessarily the definitive test, but it is the best thing I could come up with on short notice. If there is a lot of blowby, this obviously won't be of much help.

See the picture below to see the breather tube where in connects to the throttle body. It is close to the TPS and runs over the top of the IAC.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

Mustang FAQ - Wiring & Engine Info Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pinout

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif