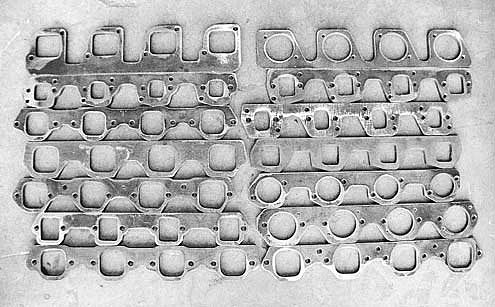

There are many types of headers available for your FOX chassis car. There are shorty headers, long tube headers, mid length headers, front exit headers, and maybe some I can't think of. Our company (RCI Headers) manufactures Long Tube Headers, Mid Length Headers, and Front Exit Headers, in primary sizes from 1 3/4" up to 2 1/4". The first consideration is, "what am I going to do with the car?" Is it a street car, or a drag car, or a street/strip car? The majority of people that call me on the phone tell me they have a street/strip car, or at least, they think they do. I ask them, "How many miles do you drive your car a year?" The average is 6,000 to 7,000 miles. Then I ask them, "How many times a year do you race your car at the drag races?". Answer, "Oh, maybe four or five times a year." My next question is, "And on the average, how many passes do you make when you go drag racing?" Answer, "Maybe about six passes." So, with that information we now understand that this enthusiast runs his car at the track maybe five times a year and averages six passes each time. Those six passes (at a quarter mile per pass) equal 1 1/2 miles, multiplied by five times a year, for a grand total of 7 1/2 miles of racing, and maybe 6,000+ miles of street use.

Folks, that is not a street/strip car. That is a street car that is used for racing a few times a year. Does he need an all out race header or a high performance street header? Some of you guys probably think that an all out race header will work great on the street. But think about it, an all out race header is designed to make horespower above 6,000 RPM, or 7,000 RPM. A well set up drag car leaves the starting line at the drag strip at about 5,000 RPM. They have no interest in mid range torque (3,000 to 5,000 RPM) because the drag car does not operate in that RPM band. But that's where a good running high performance street machine operates. Most street racers rarely exceed 6,500 RPM very often, so why buy a header that is designed to function best in that range, at the expense of making power in the RPM band that the street car typically operates in?

Like almost everything else in life, header design is always a compromise. As the Marketing Manager at RCI Headers, I would like to discuss this stuff and get some feedback from you. I have been the Marketing Manager at Accufab for the last 16 years. We manufactured Throttle Bodies but we also offered RCI headers to our customers (using the Accufab name). I have retired from Accufab but am now working with Craig at RCI. I'm a "header guy". I started in this industry at Kaufmann Products in the 1980's, where we offered RCI headers. From there I started a company with Stormin Norman Gray, and offered RCI headers. I then opened up Pro Mustang Performance, and offered RCI headers. I sold that to Coast High Performance, and while I was there, offered RCI headers, and then to Probe Industries, where we offered RCI headers, and moved to Accufab in 2002, where we offered RCI headers. Over 30 years I have been working with Craig, the founder and owner of RCI headers, and now I'm working exclusively for RCI headers.

There are a lot of thing about headers that people are not familiar with and if you are interested, let's share some knowledge together, and maybe make something useful out of this thread.

George Klass

![91013606_L[1].jpg 91013606_L[1].jpg](/cdn-cgi/image/format=auto,quality=80,sharpen=1/https://stangnet.com/mustang-forums/attachments/91013606_l-1-jpg.614834/)