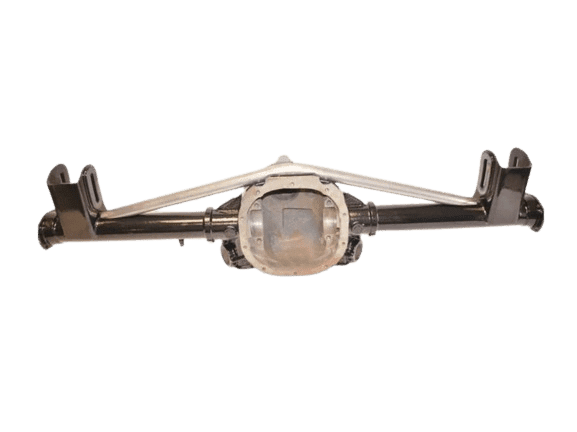

86 GT, 1400hp turbo 408w in the works, th400 behind that (standard case), and a TRZ motorsports fab'd ford 9inch housing, strange eng. center section. need help with rear end ratio and a driveshaft. i was thinking either 4.10/4.11 rear end, i believe that would be suitable, but let me know if there are better options. strange center can be any ratio from 3.40 to 4.86, so many many options are available. as for the driveshaft, i was thinking steel or chromoly, but what length and where would i buy one from? and what length yoke?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

need help with rear end and driveshaft

- Thread starter wikkedturbo408w

- Start date

-

Sponsors (?)

- Mar 2, 2015

- 6,811

- 5,849

- 203

I assume this is a drag race car. The size tire and transmission ratio are very important...also 1/8th or 1/4 mile. Intake and camshaft are also important....the power band determines the rpm...that translates to rev of the tires...that calculates to ground speed.

There is a science to choosing correct rear ratio. If your set up isn't dialed in and properly chosen you can end up spending a bunch of money to get the result you want. Most would say throw a 4.86 at it...but that could loose you time at the top end.

If x rpm multiplied by y gear = z ground speed. The limit is weight...traction...and power. All that mass has to be able to move at such and such rpm and you have to be able to put the power down.

You have a 1400hp car. If you want some real info hit up Hurricane Racing tours on FB. We have a bunch of cars making that and more. The info you need wouldn't come from a novice racer like me.

There is a formula floating around to choose the rear gear ratio.

Is your engine going to come with a dynamic sheet ?

There is a science to choosing correct rear ratio. If your set up isn't dialed in and properly chosen you can end up spending a bunch of money to get the result you want. Most would say throw a 4.86 at it...but that could loose you time at the top end.

If x rpm multiplied by y gear = z ground speed. The limit is weight...traction...and power. All that mass has to be able to move at such and such rpm and you have to be able to put the power down.

You have a 1400hp car. If you want some real info hit up Hurricane Racing tours on FB. We have a bunch of cars making that and more. The info you need wouldn't come from a novice racer like me.

There is a formula floating around to choose the rear gear ratio.

Is your engine going to come with a dynamic sheet ?

it doesn’t come with a dynamic sheet, we’re building it ourselves. but i very, VERY much appreciate the help you’ve given. that’s gonna be a ton of help when i get to that stage in a few monthsI assume this is a drag race car. The size tire and transmission ratio are very important...also 1/8th or 1/4 mile. Intake and camshaft are also important....the power band determines the rpm...that translates to rev of the tires...that calculates to ground speed.

There is a science to choosing correct rear ratio. If your set up isn't dialed in and properly chosen you can end up spending a bunch of money to get the result you want. Most would say throw a 4.86 at it...but that could loose you time at the top end.

If x rpm multiplied by y gear = z ground speed. The limit is weight...traction...and power. All that mass has to be able to move at such and such rpm and you have to be able to put the power down.

You have a 1400hp car. If you want some real info hit up Hurricane Racing tours on FB. We have a bunch of cars making that and more. The info you need wouldn't come from a novice racer like me.

There is a formula floating around to choose the rear gear ratio.

Is your engine going to come with a dynamic sheet ?

You want to calculate the speed of the car going through the traps. With 1400hp in foxbody, I'm guessing that to be around 150mph Take your dyno graph, and line through the curve to find the high RPM that you want the car to pass the traps at. Basically you want the shift light to come on as you are passing the 1/4 mile mark. That gear ratio is going to be very different for a turbo car that you shift at 6500rpms and an NA car you shift at 8500rpms.

Have you committed to a 9" axle? Those aren't as popular as they used to be, since they rob a lot of power. The 8.8" axles are a lot more popular, because they can be built to handle quite a bit without as much parasitic loss.

Kurt

Have you committed to a 9" axle? Those aren't as popular as they used to be, since they rob a lot of power. The 8.8" axles are a lot more popular, because they can be built to handle quite a bit without as much parasitic loss.

Kurt

Chromoly on the shaft for sure . You’d want their 1350 yoke . Your rear gear is going to depend on rear tire size, first gear , final rpm through the stripe .86 GT, 1400hp turbo 408w in the works, th400 behind that (standard case), and a TRZ motorsports fab'd ford 9inch housing, strange eng. center section. need help with rear end ratio and a driveshaft. i was thinking either 4.10/4.11 rear end, i believe that would be suitable, but let me know if there are better options. strange center can be any ratio from 3.40 to 4.86, so many many options are available. as for the driveshaft, i was thinking steel or chromoly, but what length and where would i buy one from? and what length yoke?

Look up starting line ratio and do the math on that .

i haven’t fully committed to a 9”, no. an 8.8 doesn’t sound like a bad idea after what i’ve heard here. now this car is still being built, so the dyno sheets and graphs won’t come for a while.You want to calculate the speed of the car going through the traps. With 1400hp in foxbody, I'm guessing that to be around 150mph Take your dyno graph, and line through the curve to find the high RPM that you want the car to pass the traps at. Basically you want the shift light to come on as you are passing the 1/4 mile mark. That gear ratio is going to be very different for a turbo car that you shift at 6500rpms and an NA car you shift at 8500rpms.

Have you committed to a 9" axle? Those aren't as popular as they used to be, since they rob a lot of power. The 8.8" axles are a lot more popular, because they can be built to handle quite a bit without as much parasitic loss.

Kurt

i haven’t fully committed to a 9”, no. an 8.8 doesn’t sound like a bad idea after what i’ve heard here. now this car is still being built, so the dyno sheets and graphs won’t come for a while.

It's just easier, because you can get a factory axle, and have it built. I think Moser can build you a whole axle with 9" ends shipped to your door.

Kurt

i was actually looking at moser's website and rear end options right as you replied lol. looks like i might have an 8.8 assembly with 9in ends built for me, few $k but i'm fine with that. thinking 4.10 or 4.30, not too much low end and just enough top end. maybe 35-40 splines, which yoke would i go with? im guessing the one made for a 79-04 setup, considering this is an 86. this should be good for say my 1500 crank hp?It's just easier, because you can get a factory axle, and have it built. I think Moser can build you a whole axle with 9" ends shipped to your door.

Kurt

If you are not just bench racing or trolling with those numbers, I’d like to see and hear what all in in this engine and chassis.

nah man, i'm 17 going on 18 and this is my 86 fox that we're building right now, and probably for the next maybe year or two, going for mark miller's stock block record for a SBF, 4.97@139. single BW 88, 408w stroker, factory 2bolt, scat/dss forged rotating assembly, bullet racing billet core custom grind turbo cam, holley hi ram, tfs highport 240 heads from TEA, and the chassis will be a wild ride's 12 point or 25.2 cage, haven't decided yet, schoneck composites doors, hatch, front end, dedicated track car. a high 4-sec 1/8 time is for sure no joke lol.If you are not just bench racing or trolling with those numbers, I’d like to see and hear what all in in this engine and chassis.

That explains the unusual combo of goals and questions. It should be exciting when it hooks, and more exciting if it doesn’t! Please take pictures and keep us updated on your progress. That’s a lot of power, even for a stock 351W block. Good luck!

i was actually looking at moser's website and rear end options right as you replied lol. looks like i might have an 8.8 assembly with 9in ends built for me, few $k but i'm fine with that. thinking 4.10 or 4.30, not too much low end and just enough top end. maybe 35-40 splines, which yoke would i go with? im guessing the one made for a 79-04 setup, considering this is an 86. this should be good for say my 1500 crank hp?

You are going to want 40 spline axles for that. I just dropped $4k on an axle, and it took about 8 months waiting on parts and fabrication. Stupid Covid. You fill out this form right here, just about anyway you want it.

M88 8.8" Housing & Axle Package - Moser Engineering

M88 8.8' Housing & Axle Package Comes standard with an all new Moser M88 Housing casted from the best nodular steel and OEM located mounting provisions, Axles, Axle Bearings and Seals, Wheel Studs, 3' DOM seamless tubing. (stock width unless specified otherwise)

This is for their M88 axle, which is a brand new piece, not fabbed from an existing axle. They build you a brand new one off axle, and ship it to you. I honestly think it would have been cheaper than the route I went. The only thing you will have to do is have brace bars welded on for the power level you are looking at. They will even through 4 piston drag brakes on it for you. They will put the Moser kit on there, or the Willwood Dynalite, which is the preferred kit for drag racing.

I actually out of curiosity just priced it out for you. An axle for your car would be $3395 with the Wilwood brakes on it. You are not going to get axle fabbed for that price. I think you still would have to buy an axle girdle for it. You are going to want to get a brace kit like this welded on.

8.8

www.teamzmotorsports.net

Wild Rides makes some great stuff, and they have been in business a long time. The selling point for me on their cages is that every single cage is assembled inside a test chassis before it ships out. They guarantee the cage will clear the arm rests. You are also going to want to look at their torque box reinforcement stuff.

Kurt

Last edited:

The removable carrier on a 9” makes swapping gears easier than changing gears under the car on an 8.8 or 12 bolt. It can be done on the bench and be ready to drop in. While you are tuning, it can make a gear change a lot easier or at least more comfortable.

The removable carrier on a 9” makes swapping gears easier than changing gears under the car on an 8.8 or 12 bolt. It can be done on the bench and be ready to drop in. While you are tuning, it can make a gear change a lot easier or at least more comfortable.

Yes, that is the upside to a 9." However, if you are chasing a stock block 1/8th mile record, you need shed every ounce of weight, and every bit of parasitic drive train drag. The 9" has a lot of that.

Kurt

so i've basically decided on purchasing a moser engineering M88 customized to my specs, so i could possibly reuse it after the stock block goes and i build a dart block sbf and look for 2k+ hp. i appreciate all the help from y'all, really helped me decide on a better setup for the drivetrain.Yes, that is the upside to a 9." However, if you are chasing a stock block 1/8th mile record, you need shed every ounce of weight, and every bit of parasitic drive train drag. The 9" has a lot of that.

Kurt

no budget is not the reason, i'm chasing mark miller's record because i want to beat that world record.Why waste your time with the stock block record ? If budget is the reason , there is nothing budget about a 25.2 car .

Just a point of reference for me. Does your family race or something? I commend you for setting such a high goal, but I'm curious as to your back ground. To be fair I do not race, have not raced, and have no desire to come anywhere close to where you are trying to go. This car is going to be insanely expensive. I'd guess in the 100k+ range to do everything you are describing and keep it as safe as possible.

Too bad he does not have a quick change rear end around while setting up the combo and reinforced 8.8”. I do not know if one would handle that much power, but they are both useful and have to add speed from the cool factor.Yes, that is the upside to a 9." However, if you are chasing a stock block 1/8th mile record, you need shed every ounce of weight, and every bit of parasitic drive train drag. The 9" has a lot of that.

Kurt

my family, mainly just my dad, had a few badass cars back in the day, but nothing along the lines of what i wanna do. i’ve grown up around friends and their families who are into hardcore x275, LDR and big tire class street racing/strip racing. i’ve always been raised ford, and i’m a particular fan of small block fords. and i’ve always been a technical motor guy, so i’d like to be an engine builder like Kaase or Disomma. racing professionally within the engine building is my dream. this car surprisingly is looking to be under $65-$70k. hopefully lol, i am only 17 and i’ll be 18 next spring, getting another job at SCE gaskets here in TN in the spring as well so the budget will increase.Just a point of reference for me. Does your family race or something? I commend you for setting such a high goal, but I'm curious as to your back ground. To be fair I do not race, have not raced, and have no desire to come anywhere close to where you are trying to go. This car is going to be insanely expensive. I'd guess in the 100k+ range to do everything you are describing and keep it as safe as possible.

Similar threads

- Replies

- 1

- Views

- 3K

- Replies

- 182

- Views

- 27K

- Replies

- 13

- Views

- 12K