Got some things done over the weekend. A lot of small details - I guess I will go ahead and bore you guys with the details:

Pulled the 31 spline yoke from the 98 driveshaft and put it on my aluminum shaft so I can use it with the current T45. I replaced the U joint with a new MOOG greaseable joint while I was at it. I bought harbor freight 5 inch table vise for this reason alone and it is well worth it. A long over due purchase anyway.

*Ignore the mess! My garage is all clean now I promise

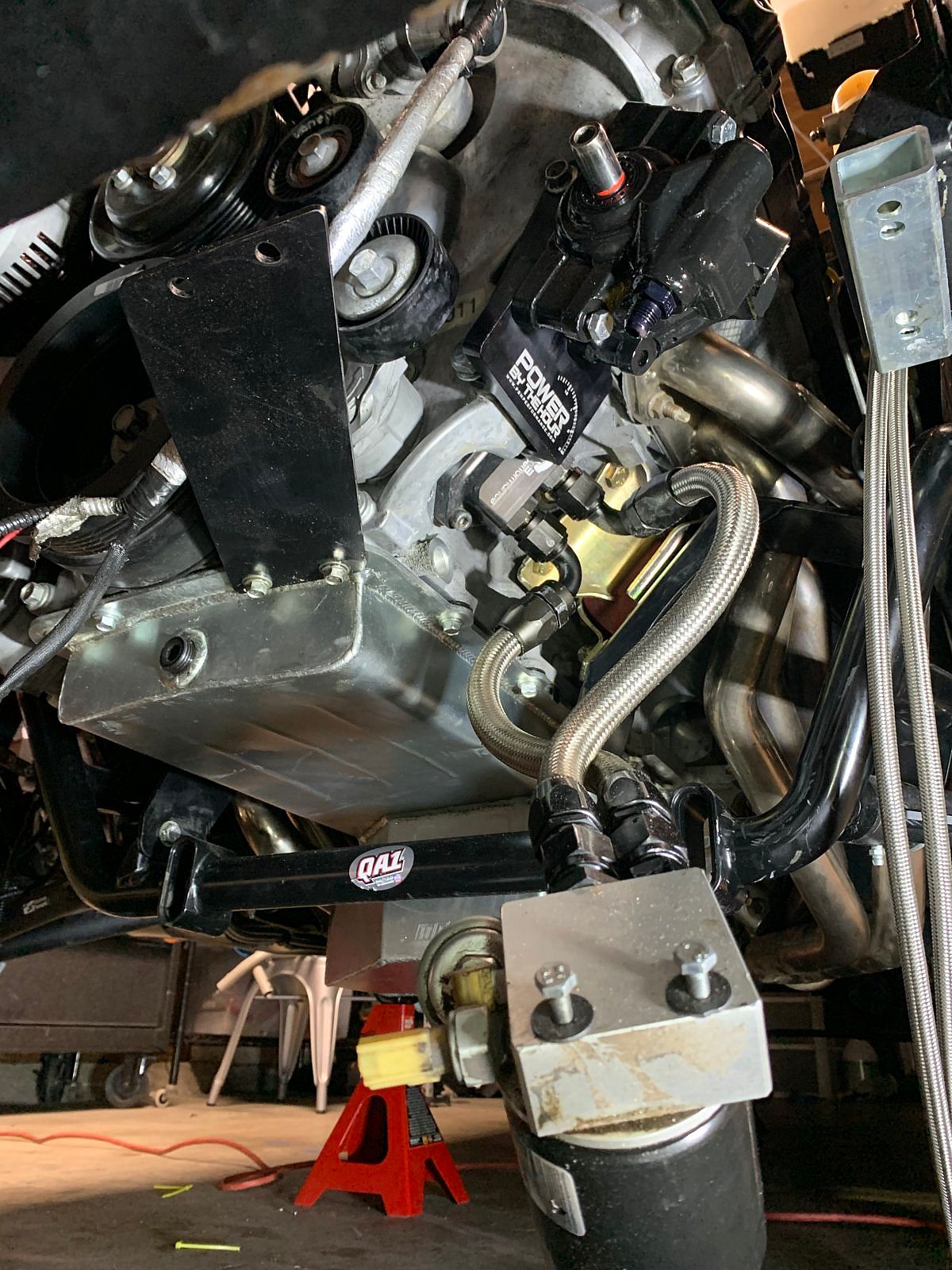

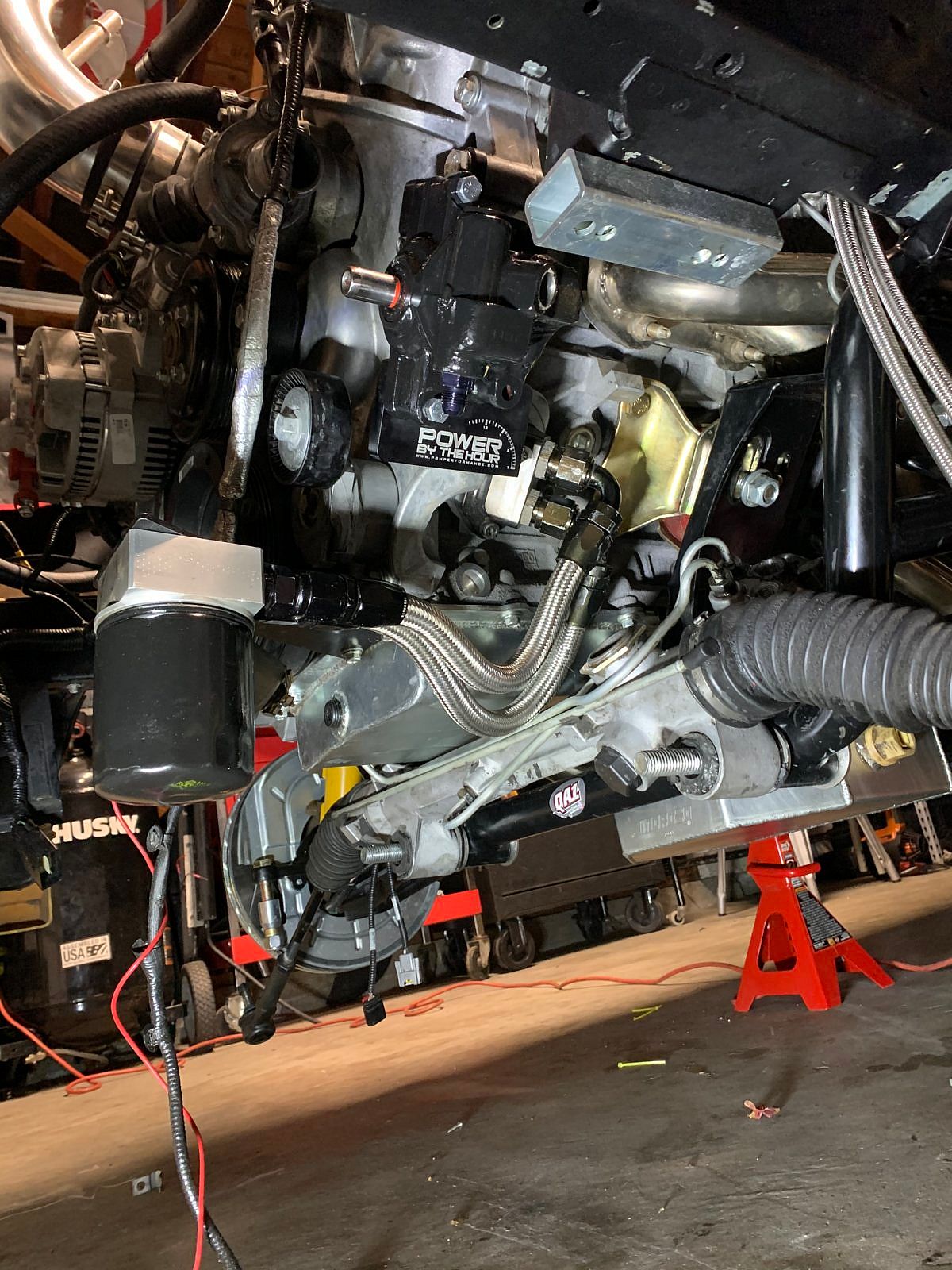

Painted the steering rack, PS pump, and the steering shaft all black while I have them out. I used Rustoleum high heat paint from home depot. Came out good, better than banged up look they had before. Now I have to try my best not to bangh them up again, but of f-ing course,. I realized that I would like to pull the barb out of the PS pump and tap the hole for AN fitting... That is going to mess up the paint a bit

Chasing correct fittings for your PS rack is never fun.. I am already down 4 fittings and none of them fit properly. I have concluded that the fittings on our ford PS racks are NOT metric. I know everyone wants to tell me to get the maximum motorsports fittings but I say they can suck it - they want nearly $50 for 2 fittings that are widely available in the industry... Dont get me wrong I like maximum, but the fact that they wont share the measurements and want to charge almost $50 for two fittings give me some bad taste in the mouth.

For the low pressure port on the rack, everyone claims it should be M16x1.5. I started off with a Fragola (

460816-BL) -8 AN to 16mm x 1.5 Male. Did not want to thread all the way in. I stopped there and then went to get Earl Performance (961955ERL) Steel power steering fitting with 16mm x 1.5 male threads. This one wouldnt even thread in to begin with.

The high pressure port is supposed to take in 14mm x 1.5 and I was able to get the adapter fittings screwed in but both 14mm fittings I got screwed in rather loose. Even though, I was able to screw in and tighten, it is not the perfect fit. I suspect that it has different threads than 14mm x 1.5 but it was close enough that the 14mm was able to fit.

This is where I stopped at yesterday. I will just take my rack to the JBA Speed Shop a few miles away from me and have them help me get the correct fittings. May be SAE after all. Cool folks over there I am positive they should square me away.

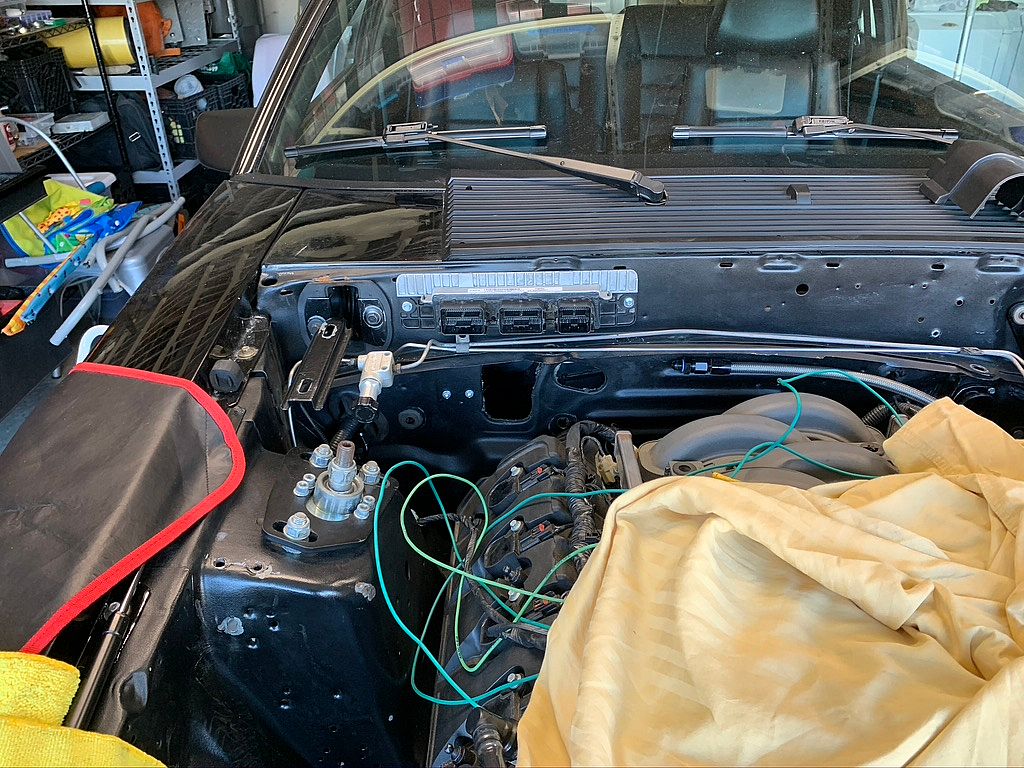

Mounted the ECU in the firewall. This is not a show car so I was perfectly fine with this mounting location. Clean enough to me. I pretty much forgot all about the strut tower brace, but I think I may have lucked out and managed to leave enough room for the STB to fit under the ECU. Pretty sure the STB I have wont work with the coyote without modifications anyway so I will get to that later.

for miles on the car since then. I was DDing something else by the time I did the new motor etc.

for miles on the car since then. I was DDing something else by the time I did the new motor etc.