Nope. I made a few attempts but it's still pending. These bolts aren't even corroded, at least not from what I can see. They are still clean with nice threads. They are just REALLY stuck in there.

Those seat belt bolts are 7/16-20. I bought a nut and threaded it onto the backside and welded it on. Proceeded to twist it off twice. For some reason I just can't get a solid weld on it. I'm just going to buy a couple good drill bits and drill it out and rethread the hole.

On the other side, same thing. Heated the bolt out and tried to remove it but the torx shape stripped. I welded a nut onto it, but decided to let it cool off before i try cranking it off. That nut actually seems like it will hold, but I'll only have one attempt to remove it I want to jack up the car and really clean up the threads and try some penetrating fluid in there for some time, and then heat up the backside and attempt to remove it. My goal is to get at least one side out and only have to drill the other.

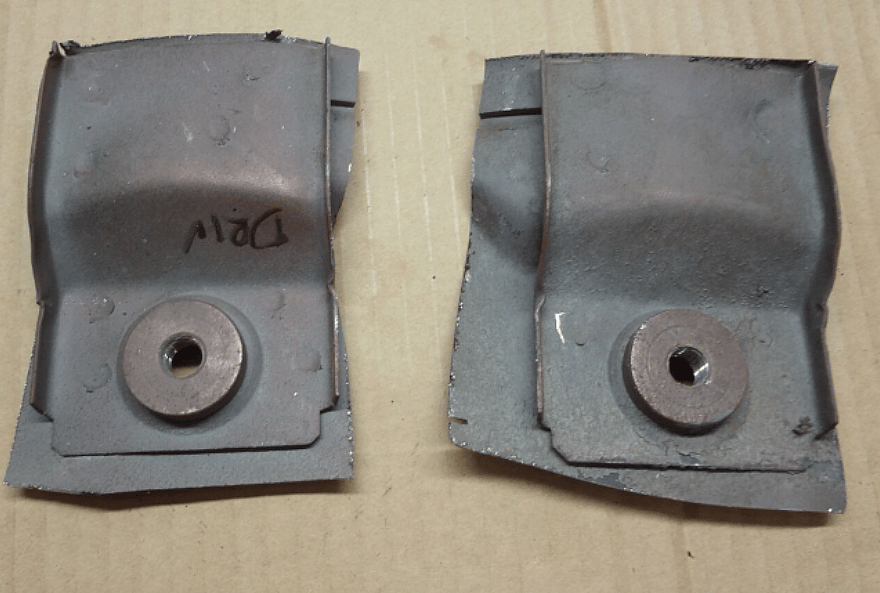

Asa backup to all that, i bought these. If i can't get the bolts out, or mess up the threads in the process, i'll just drill out the spot welds and weld these new plates on. I really hope it doesn't come to that.