Removing the intake, upper and lower to address vacuum leak. I began today to pull the intake and fix the running issues. Fairly confident the main culprit in it's not running well all center on a intake leak near the front of the engine under and behind the thermostat housing.

While I was doing wire connectors, cleaning with contact cleaner and dielectric grease, I got some of the contact cleaner into the filter. It was running at the time I was messing with the mass air sensor, and spray got in the air filter and the rpm's went up, alot up! I had planned on getting some starter fluid for finding leaks but the contact cleaner seemed to work good enough. So I started spraying along the intake seam. When I sprayed under the thermo housing the R's went up. After verifying a couple more times I was confident I found the issue. Previous owners had removed any gaskets and sensors, new sealer and clean threads to prove it. Prior owners seemed to stop problem searching at the intake level as the gasket and all the bolts are covered with grease and dirt showing they have not been touched at least in a very long time. Nobody wanted to go in this far I guess.

So that's where I am. I plan to yank the intake, replace gaskets and clean parts. I need to fix the linkage proper and do something with the heater hoses, not sure what. But thats the plan and we all know how plans go!

Beginning the tear down.

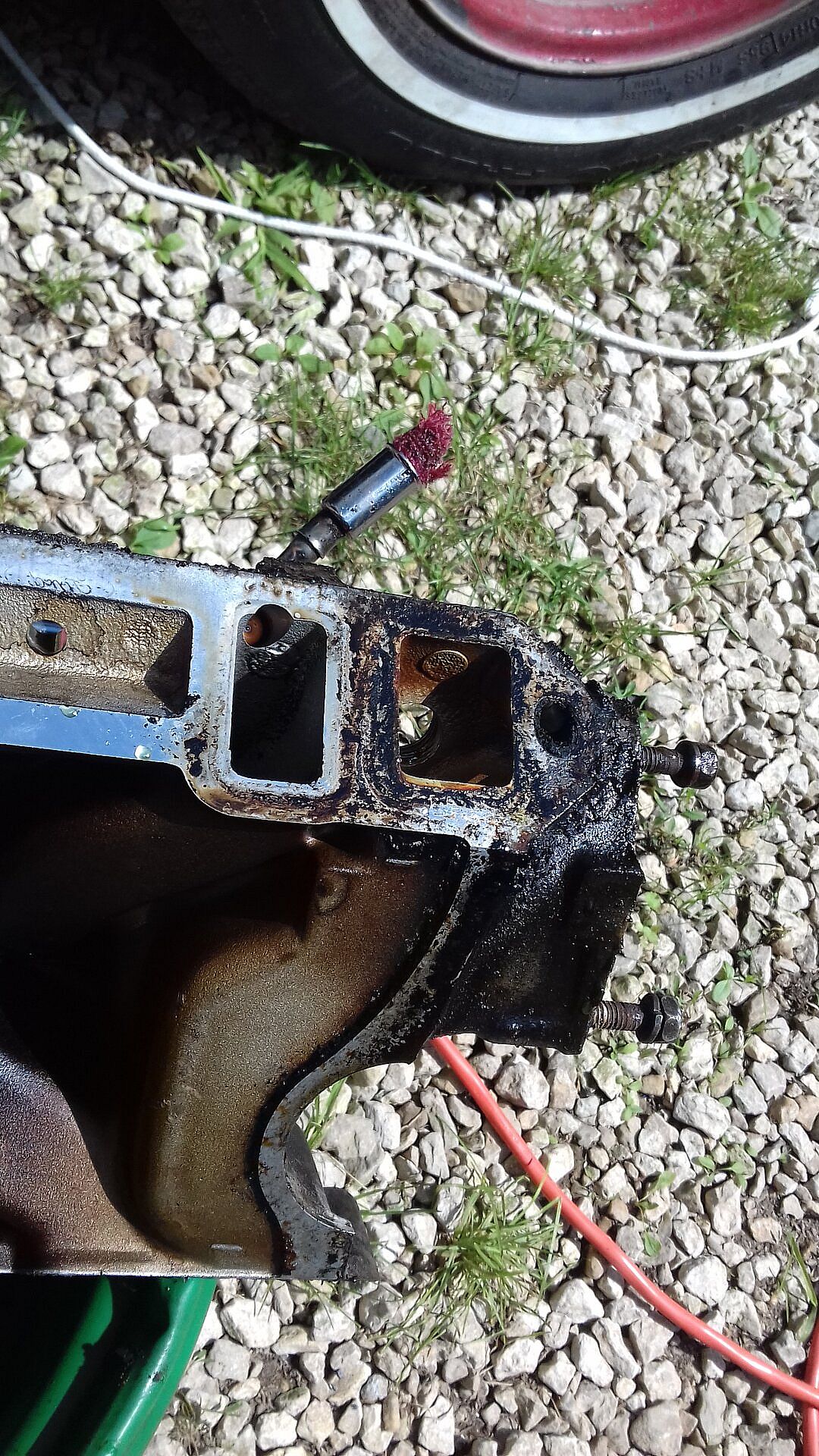

Here are some shots of the heater lines to sort out. There are some really tight turns here to deal with, not real sure on how to go about dealing with this. Some elbow's and hose maybe I don't know of what.

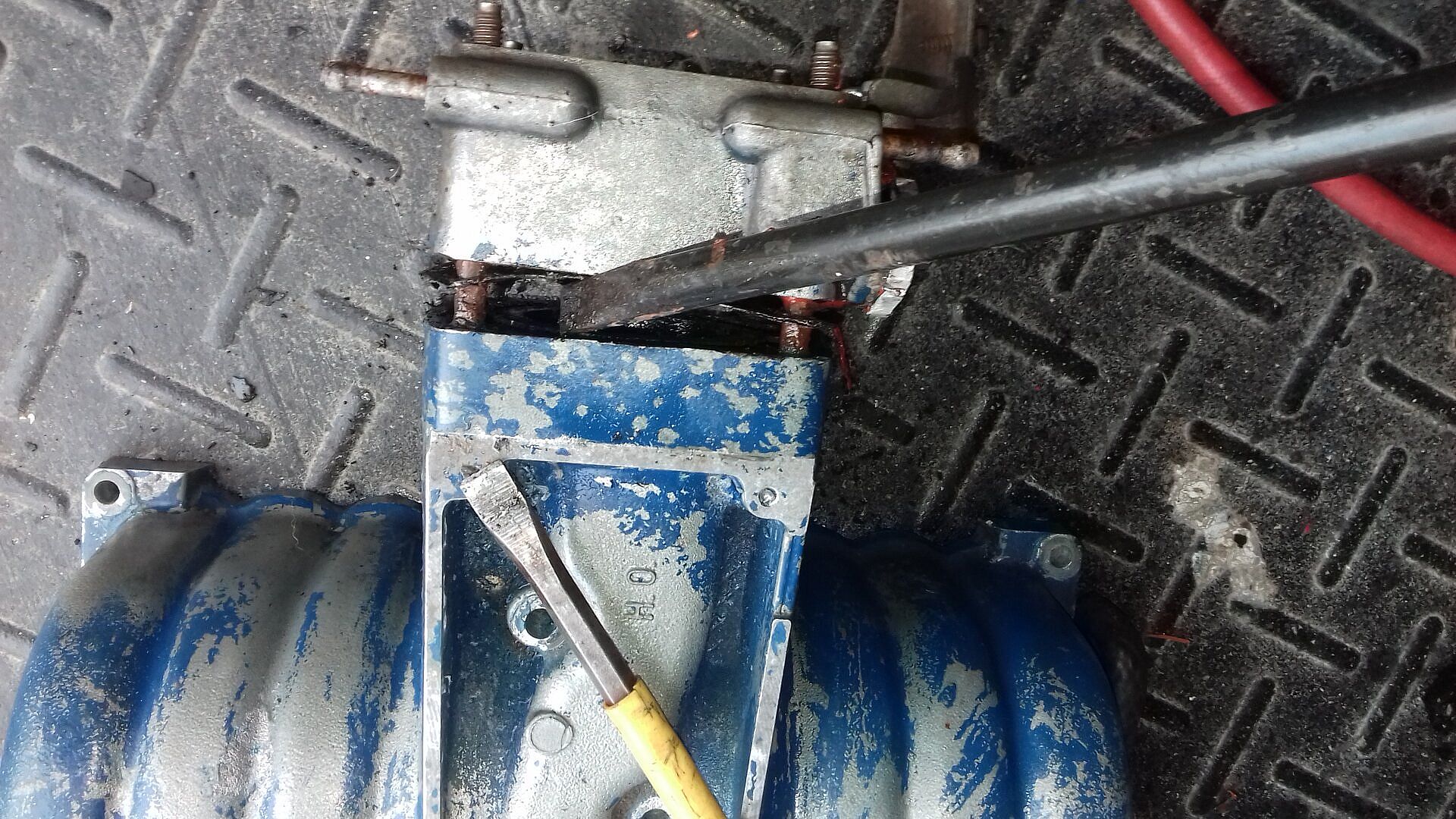

In this pic you can see the hose mess and the pedal linkage problem. The throttle lever can be seen in the middle here and needs to be proper connected to the throttle body. May just get a new pedal/cable assembly for this issue still weighing my options here.

Then there's the water lines the run the length of the manifold. They are rusted and I don't trust the longevity of this at all. I will be cleaning this and removing the rust and painting. I bet this is a reoccurring problem with these motors. Hopefully in cleaning I don't breakthrough and cause a leaker. You can see also on the firewall end (previous pic) that the tubing has been bent and kinked. Will deal with this when I get there.

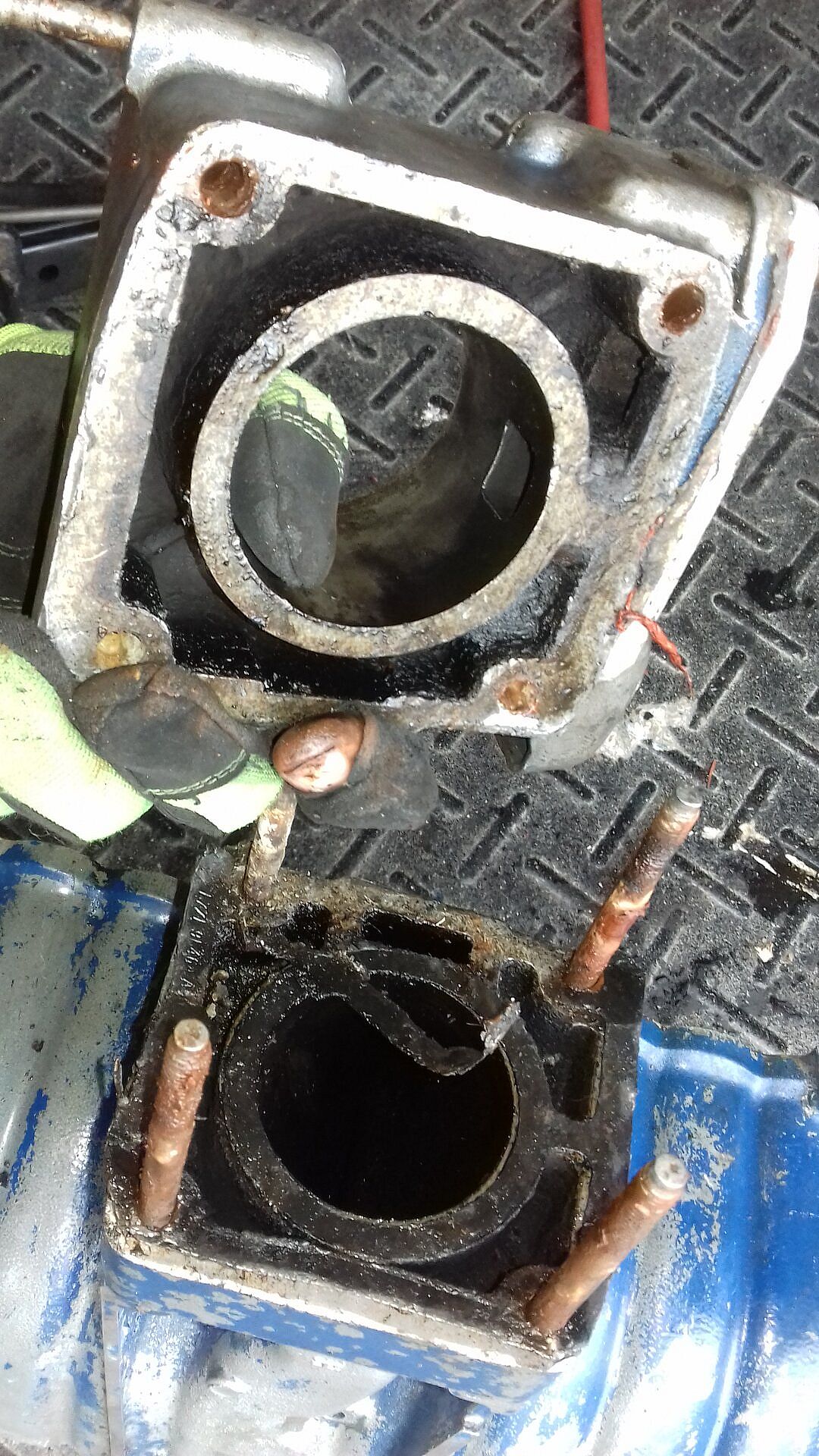

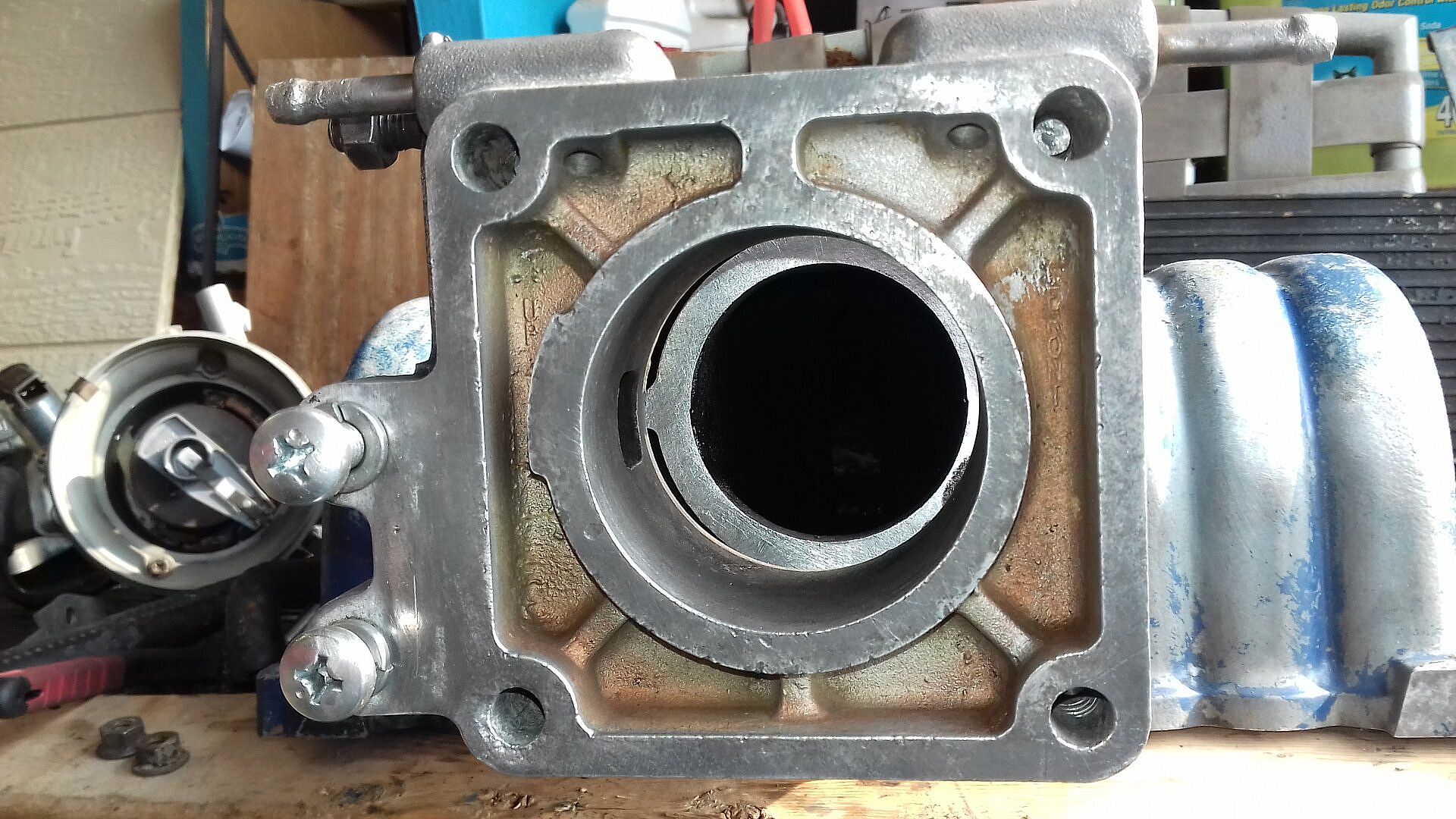

Now, the real problem! The throttle body/egr spacer was corroded onto the upper. Not just a little either. This was a nerve rattling experience trying to remove this without breaking the studs, breaking off a piece of either the manifold or spacer or cracking something. I DID manage to remove it. YIKES it was on hard!! I even used a small jack between the upper and the throttle bracket and it STILL wouldn't budge. I finally got it by using a pick to clean out around the studs so p oil could get in there. Used a razor blade to cut into the gasket seem to weaken it. After a day of picking, soaking It and repeat it finally came loose. I had to use a chisel and BFH to get the two to separate. Man was I afraid this would go south!

Here is the jack installed. I put ALOT of pressure on this and nothing!

I hid my chiseling damage on the bottom of the intake. Nothing too bad but there are gaps where I hammered in the chisel on the corners. I used the chisel so that the studs would stop it from going in too far and damaging the gasket surface. Using the crowbar to work it off and keep it even on the studs.

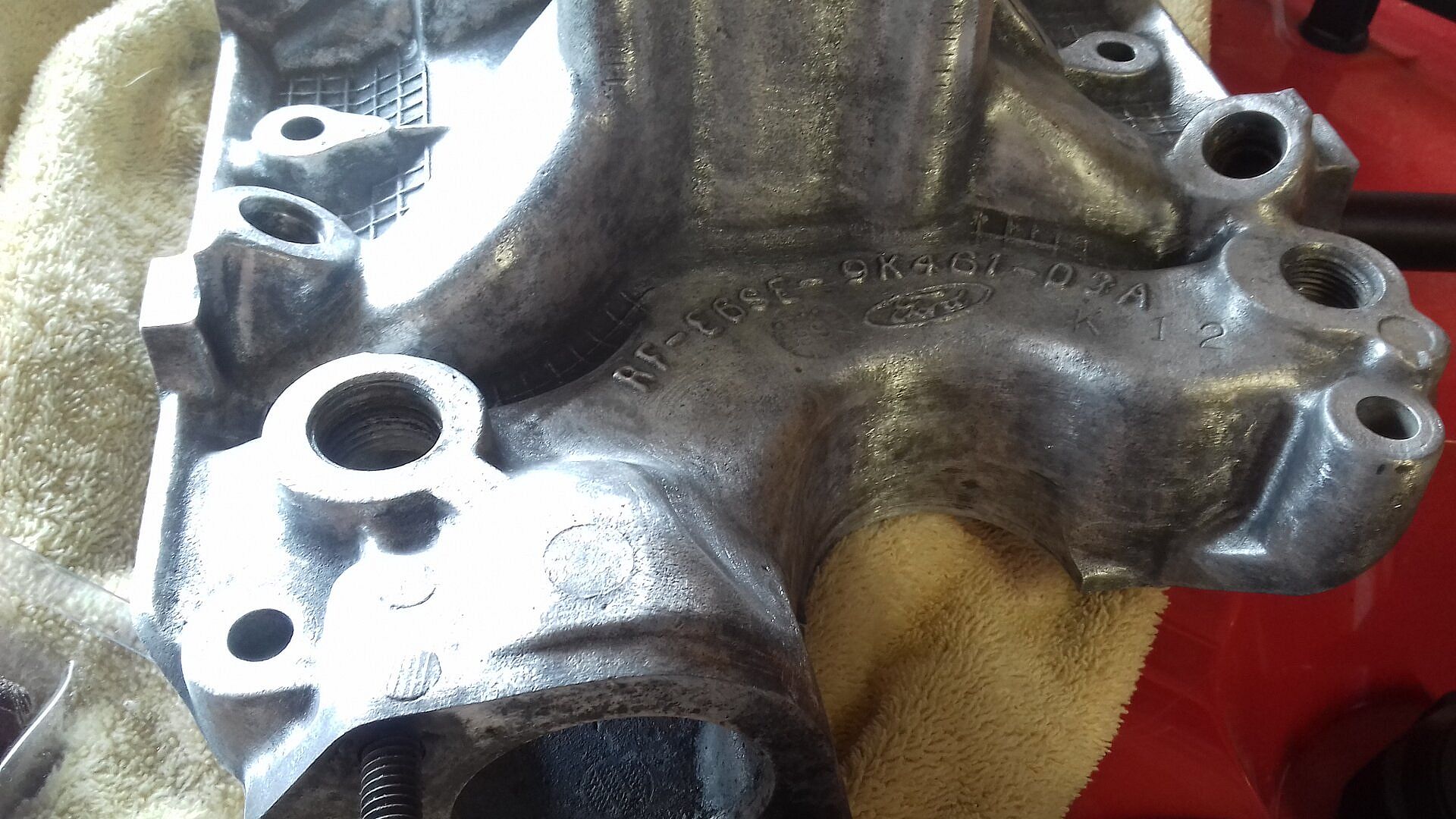

Finally success! But look at those studs and the corrosion!

Today I will be right back at it if things go right. Get the parts cleaned and remove the lower manifold. Soon will be passing the middle of this job and heading towards the finish. No big hurry though. It's fun stuff when there's no deadline. I am always open to tips and suggestions so feel free.