Jim, post #67. I like your flat bar idea. We still haven't dragged out our old PanelSpotter to try to get new tips for it. We were discussing dipping the tips in some kind of paste flux before each weld. When you parked it, the tips were getting half welded to the sheet metal part.

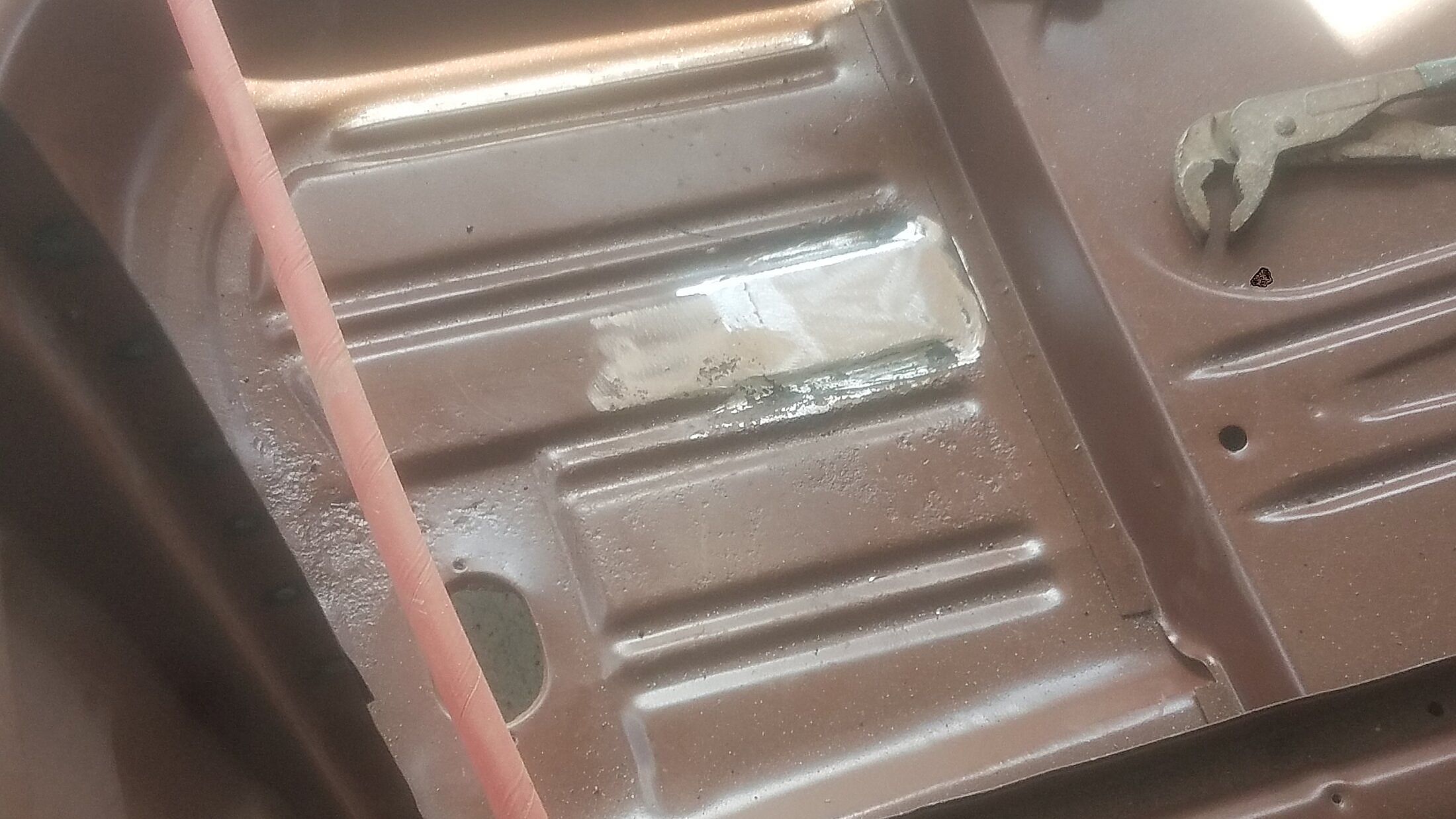

Do you have an extra drivers side coupe/fastback front torque box that you would sell? We are adding a pair to a '66 coupe that needs them. The front frame rails are tweaked up and have to be pulled back down for the fenders to fit correctly. We thought it might be a good idea to add them after the pulling, and before removing the cowl top for cowl bottom replacement.

Also, I like the looks of your fastback rear interior panels. I'd like to talk about them more in the future. Keep up the good work!