You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad MAF symptoms

- Thread starter stanggt95

- Start date

-

Sponsors (?)

Werecow91

Member

Is your distributor hooked up to manifold vacuum or ported vacuum? If your getting a mid throttle stumbling check there, the distributor needs to be plugged into ported vacuum.. Check out Uncle Tony's Garage on youtube, he's got a couple of videos on the subject that can explain it a lot better than I can..

Werecow91

Member

- Mar 2, 2015

- 6,828

- 5,863

- 203

Under the rotor button there should be 2 wings with springs attached to them. Those weights and springs control timing advance on a GM style distributor. They both should move freely and smoothly.

Under the rotor button there should be 2 wings with springs attached to them. Those weights and springs control timing advance on a GM style distributor. They both should move freely and smoothly.

Alright, I'll check that first. thanksUnder the rotor button there should be 2 wings with springs attached to them. Those weights and springs control timing advance on a GM style distributor. They both should move freely and smoothly.

Do you have a dial back timing light? That will tell you what the advance is and when it comes in.

Honestly, I think you need to look to the carb/fuel system for this problem.

Carbs are kind of a mystery around here.

Curious, what air cleaner are you using? Some times if the top is too close to the vent tube it will not vent at high rpms making it seem like it is running out of gas.

Honestly, I think you need to look to the carb/fuel system for this problem.

Carbs are kind of a mystery around here.

Curious, what air cleaner are you using? Some times if the top is too close to the vent tube it will not vent at high rpms making it seem like it is running out of gas.

Do you have a dial back timing light? That will tell you what the advance is and when it comes in.

Honestly, I think you need to look to the carb/fuel system for this problem.

Carbs are kind of a mystery around here.

Curious, what air cleaner are you using? Some times if the top is too close to the vent tube it will not vent at high rpms making it seem like it is running out of gas.

I know there's no timing light. To be honest this is my first round with American muscle. In the past I've had Honda/acura. This was all done by a previous owner. I just picked it up this past Saturday. I've been driving it since then just to see what all I'm gonna have to fix. So far, it's this issue, the oil pan gasket, leaks anti freeze somewhere, the tie rods, the steering rack/pinion, all need replaced, and more than likely the fuel pump.

What year is this car? It appears to be a sn95.

What is your fuel pressure at idle and at say 3k rpms?

I looked at the pic and your air cleaner should be good.

What is your fuel pressure at idle and at say 3k rpms?

I looked at the pic and your air cleaner should be good.

It is a 1995...I just picked up the car last Saturday and this is my first time around with a mustang. A buddy of mine is gonna take a look at it when we get off work. From the picture he thinks the motor has been swapped. I'm not sure about the fuel pressure. I'll have to check. All the work was done by a previous owner. It all looks fairly new. I'm wondering if maybe the carburetor just needs to be adjusted.What year is this car? It appears to be a sn95.

What is your fuel pressure at idle and at say 3k rpms?

I looked at the pic and your air cleaner should be good.

- Mar 2, 2015

- 6,828

- 5,863

- 203

Everything does look new. That distributor is probably not the issue.

I know a bunch about carburetors....and that one in particular.

The first thing you need to do is buy an air fuel ratio gauge. One of the cheap ones from advance auto, autozone, or O'Reilly.

They are cheaper at the parts stores usually.

Then, buy a factory 1990 mustang o2 sensor...I know yours is a 95 ( I just don't know if it takes a different sensor and I know 1990 will work.

Hook the gauge and screw the sensor in a bung on the headers or in the lower exhaust pipe. You only need it in one side.

There is a little lever on the left side of the carb.

The position of that lever controls how much fuel you get when you hit the gas. Its called a power valve.

You want to adjust the two screws on the front until you get green lights ( stoich ) on the gauge at idle. It should swing between the green and barely into the yellow or red. When driving the gauge will be in the lean when decelerating...tip into the top of green into rich when pressing the gas but during cruising should be green.

There should be a part number stamped into the base somewhere. The most common issue that people get is a carburetor that is too big. It should be a 1902 part number ( 500cfm ) for a almost stock 302...the 1905 ( 650cfm ) for a mildly to built 302. The 650 was almost too big for 306 with E camshaft, 1.6 rockers, and ported iron heads. It did work and gave me over 20mpg on the highway.

That air fuel ratio gauge is the trick. As temperatures change you will find yourself having to tweak those two screws upfront to get it to idle smooth. Do not turn them all the way in tight or you will damage them. Screw them in, with the car off, all the way until you feel them stop. Now, back them out 1.5 turns. This is the starting point for adjustment. Turning clockwise will lean it out...counter clockwise make it richer.

Once the carburetor is in the green ( stoich 14.7 to 1 ) check the timing and set at 10 degrees ( stock ) about 12 degrees for a mild build. A heavier build may need 14 degrees. Timing lights are so cheap and easy to use ( harbor freight ). Rev the engine to about 2k and timing should advance to about 20 degrees...at full rev it should max out at 26 degrees.

The linkage to the secondaries ( two holes in the back ) can be set to open sooner or later. This is set with the car off...its just a mechanical linkage that moves with the throttle.

Once the car is driving or revved off idle those two screws do nothing. The actual fueling comes from a needle and seat thats a little more complicated for a noob. When stabbing the throttle hard the power valve is what gives the initial rush of fuel. If it stumbles while pressing the gas hard move the wire in the lever circled to a closer or further hole.

Sorry for all the typing...I've been drinkin'

I know a bunch about carburetors....and that one in particular.

The first thing you need to do is buy an air fuel ratio gauge. One of the cheap ones from advance auto, autozone, or O'Reilly.

They are cheaper at the parts stores usually.

Then, buy a factory 1990 mustang o2 sensor...I know yours is a 95 ( I just don't know if it takes a different sensor and I know 1990 will work.

Hook the gauge and screw the sensor in a bung on the headers or in the lower exhaust pipe. You only need it in one side.

There is a little lever on the left side of the carb.

The position of that lever controls how much fuel you get when you hit the gas. Its called a power valve.

You want to adjust the two screws on the front until you get green lights ( stoich ) on the gauge at idle. It should swing between the green and barely into the yellow or red. When driving the gauge will be in the lean when decelerating...tip into the top of green into rich when pressing the gas but during cruising should be green.

There should be a part number stamped into the base somewhere. The most common issue that people get is a carburetor that is too big. It should be a 1902 part number ( 500cfm ) for a almost stock 302...the 1905 ( 650cfm ) for a mildly to built 302. The 650 was almost too big for 306 with E camshaft, 1.6 rockers, and ported iron heads. It did work and gave me over 20mpg on the highway.

That air fuel ratio gauge is the trick. As temperatures change you will find yourself having to tweak those two screws upfront to get it to idle smooth. Do not turn them all the way in tight or you will damage them. Screw them in, with the car off, all the way until you feel them stop. Now, back them out 1.5 turns. This is the starting point for adjustment. Turning clockwise will lean it out...counter clockwise make it richer.

Once the carburetor is in the green ( stoich 14.7 to 1 ) check the timing and set at 10 degrees ( stock ) about 12 degrees for a mild build. A heavier build may need 14 degrees. Timing lights are so cheap and easy to use ( harbor freight ). Rev the engine to about 2k and timing should advance to about 20 degrees...at full rev it should max out at 26 degrees.

The linkage to the secondaries ( two holes in the back ) can be set to open sooner or later. This is set with the car off...its just a mechanical linkage that moves with the throttle.

Once the car is driving or revved off idle those two screws do nothing. The actual fueling comes from a needle and seat thats a little more complicated for a noob. When stabbing the throttle hard the power valve is what gives the initial rush of fuel. If it stumbles while pressing the gas hard move the wire in the lever circled to a closer or further hole.

Sorry for all the typing...I've been drinkin'

That’s different than a Holley or Autocraft style. Thanks for the info. Is this still similar to the AFB carbs like was rumored when Edelbrock carbs first came out?

Fuel pressure seems low. The gauge fluctuates from as low as 1.5 to about 3. I'm thinking something is causing me to randomly lose fuel pressure.What year is this car? It appears to be a sn95.

What is your fuel pressure at idle and at say 3k rpms?

I looked at the pic and your air cleaner should be good.

Thanks for the detailed info. Definitely gonna have to get the air/fuel gage and follow your advice step by step. LOL I literally screen shot everything so I would have it saved. I don't have a lot of free time so it may be the weekend before I have time to mess with it. I wanna be able to daily drive this car so I need to get it right.Everything does look new. That distributor is probably not the issue.

I know a bunch about carburetors....and that one in particular.

The first thing you need to do is buy an air fuel ratio gauge. One of the cheap ones from advance auto, autozone, or O'Reilly.

They are cheaper at the parts stores usually.

Then, buy a factory 1990 mustang o2 sensor...I know yours is a 95 ( I just don't know if it takes a different sensor and I know 1990 will work.

Hook the gauge and screw the sensor in a bung on the headers or in the lower exhaust pipe. You only need it in one side.

There is a little lever on the left side of the carb.

The position of that lever controls how much fuel you get when you hit the gas. Its called a power valve.

You want to adjust the two screws on the front until you get green lights ( stoich ) on the gauge at idle. It should swing between the green and barely into the yellow or red. When driving the gauge will be in the lean when decelerating...tip into the top of green into rich when pressing the gas but during cruising should be green.

There should be a part number stamped into the base somewhere. The most common issue that people get is a carburetor that is too big. It should be a 1902 part number ( 500cfm ) for a almost stock 302...the 1905 ( 650cfm ) for a mildly to built 302. The 650 was almost too big for 306 with E camshaft, 1.6 rockers, and ported iron heads. It did work and gave me over 20mpg on the highway.

That air fuel ratio gauge is the trick. As temperatures change you will find yourself having to tweak those two screws upfront to get it to idle smooth. Do not turn them all the way in tight or you will damage them. Screw them in, with the car off, all the way until you feel them stop. Now, back them out 1.5 turns. This is the starting point for adjustment. Turning clockwise will lean it out...counter clockwise make it richer.

Once the carburetor is in the green ( stoich 14.7 to 1 ) check the timing and set at 10 degrees ( stock ) about 12 degrees for a mild build. A heavier build may need 14 degrees. Timing lights are so cheap and easy to use ( harbor freight ). Rev the engine to about 2k and timing should advance to about 20 degrees...at full rev it should max out at 26 degrees.

The linkage to the secondaries ( two holes in the back ) can be set to open sooner or later. This is set with the car off...its just a mechanical linkage that moves with the throttle.

Once the car is driving or revved off idle those two screws do nothing. The actual fueling comes from a needle and seat thats a little more complicated for a noob. When stabbing the throttle hard the power valve is what gives the initial rush of fuel. If it stumbles while pressing the gas hard move the wire in the lever circled to a closer or further hole.

Sorry for all the typing...I've been drinking

- Mar 2, 2015

- 6,828

- 5,863

- 203

1.5 to 3psi is low. Should be 5psi. Some people run at about 7. Is there an external electric fuel pump under the car ?

Back in the day we used to just take the fuel pump out of the hanger inside the trunk and run a piece of tubing to the bottom of the tank. Then we'd plumb in an electric fuel pump after the factory filter.

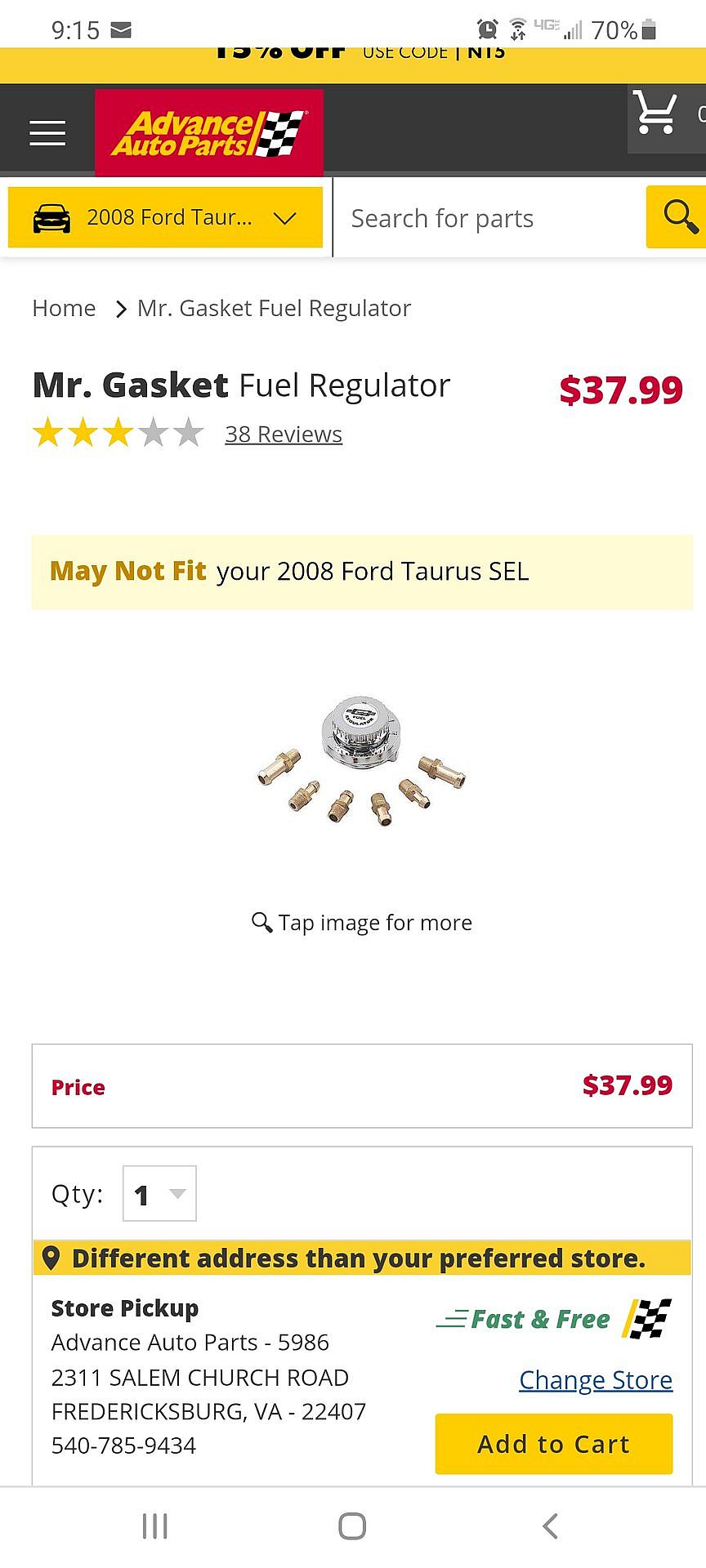

If your fuel pressure is that low I'd check that out first before touching the carb. Just a bit of advise....the ethanol in modern gas will eat up the diaphragm in a Mr.Gasket fuel pressure regulator. I used them for years but when this new gas mix came out I had to change it about every 3 months. ( daily drove my carbureted fox ).

You could have a kinked fuel hose or line, a clogged filter, bad fuel pump, fuel pressure regulator could be bad, or could be sucking air from a bad line in the fuel tank.

The way I do a carbureted car is to use a piece of fuel line and fuel line clamps ( about 2 inches long ) to run a piece of 5/16 metal line in place of the factory fuel pump. I'd leave the factory fuel filter in the same location. The fuel pump would be mounted right after the fuel filter and screwed onto the trunk floor. From there the factory line would lead up front to a rubber fuel hose and into clear ( see through) filter and then to the regulator. Ran from the regulator straight to the carburetor. My pump would put out about 8psi...I ran the regulator at 4.5 to 5psi.

This is the regulator I used...not the best but cheap and did work. It would start vibrating when is would go bad.

Hope you get it all sorted out. Looks like the PO knew what he was doing a little. Should be a simple fix to get it running right.

Back in the day we used to just take the fuel pump out of the hanger inside the trunk and run a piece of tubing to the bottom of the tank. Then we'd plumb in an electric fuel pump after the factory filter.

If your fuel pressure is that low I'd check that out first before touching the carb. Just a bit of advise....the ethanol in modern gas will eat up the diaphragm in a Mr.Gasket fuel pressure regulator. I used them for years but when this new gas mix came out I had to change it about every 3 months. ( daily drove my carbureted fox ).

You could have a kinked fuel hose or line, a clogged filter, bad fuel pump, fuel pressure regulator could be bad, or could be sucking air from a bad line in the fuel tank.

The way I do a carbureted car is to use a piece of fuel line and fuel line clamps ( about 2 inches long ) to run a piece of 5/16 metal line in place of the factory fuel pump. I'd leave the factory fuel filter in the same location. The fuel pump would be mounted right after the fuel filter and screwed onto the trunk floor. From there the factory line would lead up front to a rubber fuel hose and into clear ( see through) filter and then to the regulator. Ran from the regulator straight to the carburetor. My pump would put out about 8psi...I ran the regulator at 4.5 to 5psi.

This is the regulator I used...not the best but cheap and did work. It would start vibrating when is would go bad.

Hope you get it all sorted out. Looks like the PO knew what he was doing a little. Should be a simple fix to get it running right.

Lots of good info. Thanks. The fuel pump and fuel lines were all changed. The fuel pump is mounted to the tank. Whoever did the work also ran all new lines but left the old ones hanging there just disconnected. Its extremely loud. Isn't this the fuel filter and fuel pressure regulator? There is an allen head screw that I tried to turn thinking that may be the adjustment for the fuel pressure but it was VERY tight so I didn't force it. Could there possibly be a second fuel filter in the fuel line coming off the tank?1.5 to 3psi is low. Should be 5psi. Some people run at about 7. Is there an external electric fuel pump under the car ?

Back in the day we used to just take the fuel pump out of the hanger inside the trunk and run a piece of tubing to the bottom of the tank. Then we'd plumb in an electric fuel pump after the factory filter.

If your fuel pressure is that low I'd check that out first before touching the carb. Just a bit of advise....the ethanol in modern gas will eat up the diaphragm in a Mr.Gasket fuel pressure regulator. I used them for years but when this new gas mix came out I had to change it about every 3 months. ( daily drove my carbureted fox ).

You could have a kinked fuel hose or line, a clogged filter, bad fuel pump, fuel pressure regulator could be bad, or could be sucking air from a bad line in the fuel tank.

The way I do a carbureted car is to use a piece of fuel line and fuel line clamps ( about 2 inches long ) to run a piece of 5/16 metal line in place of the factory fuel pump. I'd leave the factory fuel filter in the same location. The fuel pump would be mounted right after the fuel filter and screwed onto the trunk floor. From there the factory line would lead up front to a rubber fuel hose and into clear ( see through) filter and then to the regulator. Ran from the regulator straight to the carburetor. My pump would put out about 8psi...I ran the regulator at 4.5 to 5psi.

This is the regulator I used...not the best but cheap and did work. It would start vibrating when is would go bad.

Hope you get it all sorted out. Looks like the PO knew what he was doing a little. Should be a simple fix to get it running right.

Attachments

They look like it, play the google game.

Look to Summit racing for fuel pumps, pay attention to how they are mounted, remember, you only need a max pressure of about 7 lbs.

Fuel lines are very important to keep from becoming a rolling fireball, if they look sketchy, fix it.

Look to Summit racing for fuel pumps, pay attention to how they are mounted, remember, you only need a max pressure of about 7 lbs.

Fuel lines are very important to keep from becoming a rolling fireball, if they look sketchy, fix it.

Yes, that is a canister style fuel filter, and that is some sort of fuel pressure regulator. I'm finding ones made by holly and summit racing that look very similar. The gauge is reading really low fuel pressure. I'm not that mechanically inclined but I would almost lean towards just adjusting the fuel pressure regulator and if that does work, swap out the fuel filter. I just don't wanna throw parts at it though and waste $$. I wish there was a way to verify where the problem is before just swapping out parts.They look like it, play the google game.

Look to Summit racing for fuel pumps, pay attention to how they are mounted, remember, you only need a max pressure of about 7 lbs.

Fuel lines are very important to keep from becoming a rolling fireball, if they look sketchy, fix it.

Similar threads

- Replies

- 3

- Views

- 998

- Replies

- 0

- Views

- 181

- Replies

- 15

- Views

- 1K

- Replies

- 6

- Views

- 497

- Replies

- 22

- Views

- 2K