Fix the codes first, You must fix the code 22...

Use a vacuum gauge to test the idle vacuum - you should see 16"-19" of vacuum at 675-750 RPM engine idle. You should see 18"-21" vacuum at 1000 RPM. If the engine will not run smoothly at 1000 RPM, you may have mechanical problems. Post any erratic vacuum readings you get and I will post the graphic chart that helps interpret them..

MAP/BARO sensor operation and code 22

Revised 24 Oct 2018 add warning about trying to measure the MAP/BARO sensor output with a common multimeter.

On a Speed Density car, the MAP/BARO sensor is connected to the intake manifold and acts to sense the manifold pressure. Lower vacuum inside the intake manifold when combined with more throttle opening measured by the TPS means more airflow through the engine. As airflow increases, fuel flow through the injectors needs to increase to keep the air/fuel ratio where it needs to be. When manifold vacuum increases, the engine is either decelerating or idling, and it needs to reduce the fuel flow through the injectors.

On a Mass Air car, the MAP/BARO sensor vents to open air and actually senses the barometric pressure due to changes in weather and altitude. Its purpose is to set a baseline for the computer to know the barometric pressure. As barometric pressure decreases, it leans out the fuel flow to compensate for less oxygen in the air. When the barometric pressure rises, it increases to add fuel since there is more oxygen in the air. The fuel requirements decrease as altitude increases, since the atmospheric pressure decreases.

Disconnecting the wiring connector from the MAP or BARO sensor will set code 22..

Misconnecting the BARO sensor to vacuum on a Mass Air car will cause the computer to lean out the fuel mixture.

Code 22 or 126 MAP (vacuum) or BARO signal out of range. The MAP or BARO sensor is pretty much the same sensor for both Mass Air & Speed Density cars. The main difference is where it is connected. Mass Air cars vent it to the atmosphere, while Speed Density cars connect it to the intake manifold vacuum. Its purpose is to help set a baseline for the air/fuel mixture by sensing changes in barometric pressure. The MAP or BAP sensor puts out a 5 volt square wave that changes frequency with variations in atmospheric pressure. The base is 154 HZ at 29.92" of mercury - dry sunny day at sea level, about 68-72 degrees. You need an oscilloscope or frequency meter to measure it. There a very few DVM’s with a price tag under $40 that will measure frequency, but there may be some out there.

Map sensor wiring:

black/white - ground

orange/white or +5 volts power

white/red signal out.

Measure the +5 volt supply using the orange/white and black/white wires

Measure the signal using the black/white and white/red wires.

The MAP/BARO sensor is mounted on the firewall behind the upper manifold on 86-93 Mustangs.

The Baro or MAP sensor can only be tested using a real frequency meter. The sensor output is a square wave which cannot be accurately measured with a common multimeter. Run the test key on, engine off.. The noise from the ignition system will likely upset the frequency meter. I used a 10 x oscilloscope probe connected from the frequency meter to the MAP/BAP to reduce the jitter in the meter's readout. And oscilloscope is very useful if you have access to one or know of someone who does. With an oscilloscope, you can see the waveform and amplitude.

If it is defective, your air/fuel ratio will be off and the car’s performance & emissions will suffer

Some basic checks you can make to be sure that the sensor is getting power & ground:

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1 ohm. Next check the resistance between the black/white wire and the negative battery cable. It should be less than 1.5 ohm.

The following power on check requires you to turn the ignition switch to the Run position.

Use a DVM to check for 5 volts on the orange/white wire. If it is missing, look for +5 volts at the orange/white wire on the TPS or EGR sensors. Use the black/white wire for the ground for the DVM.

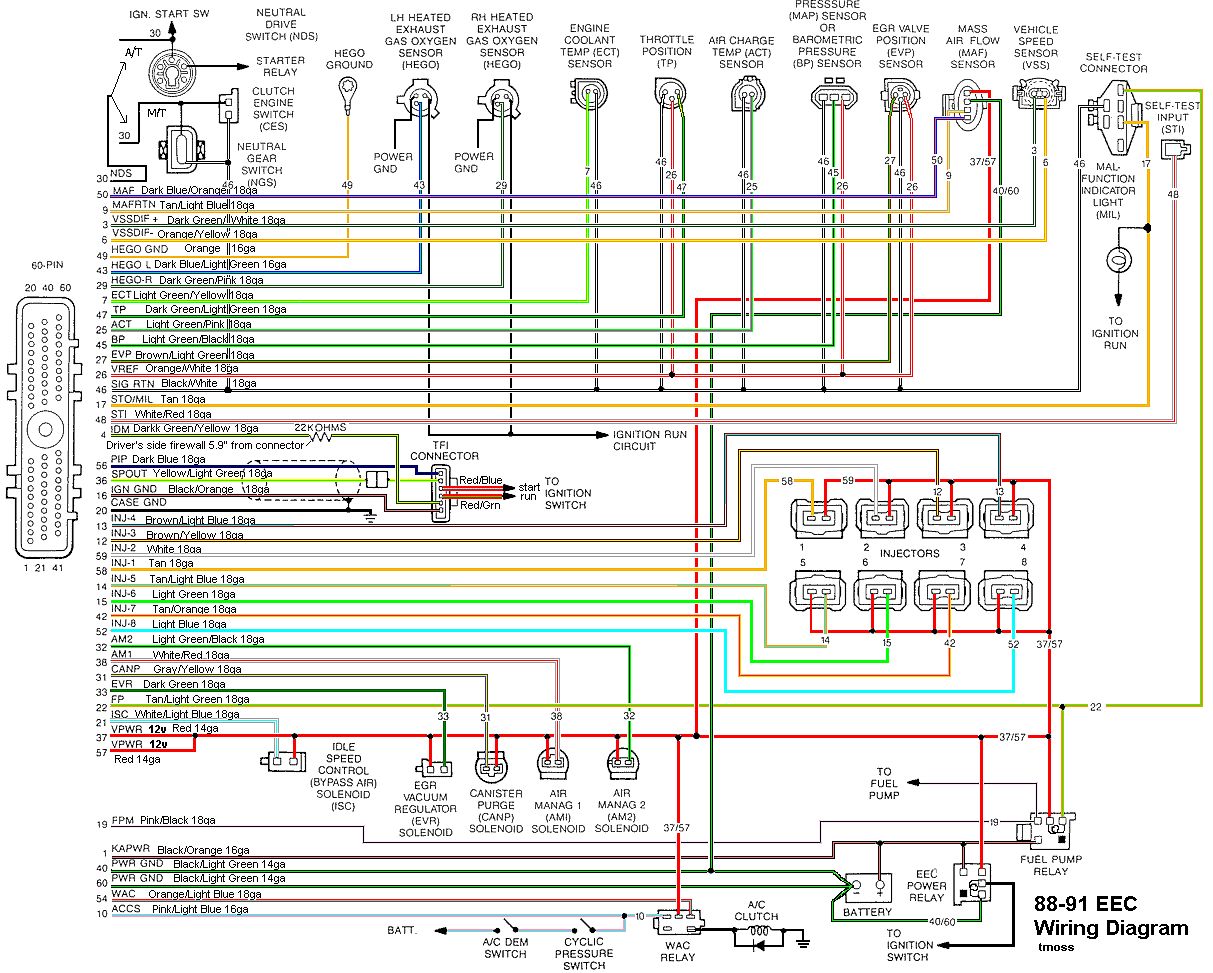

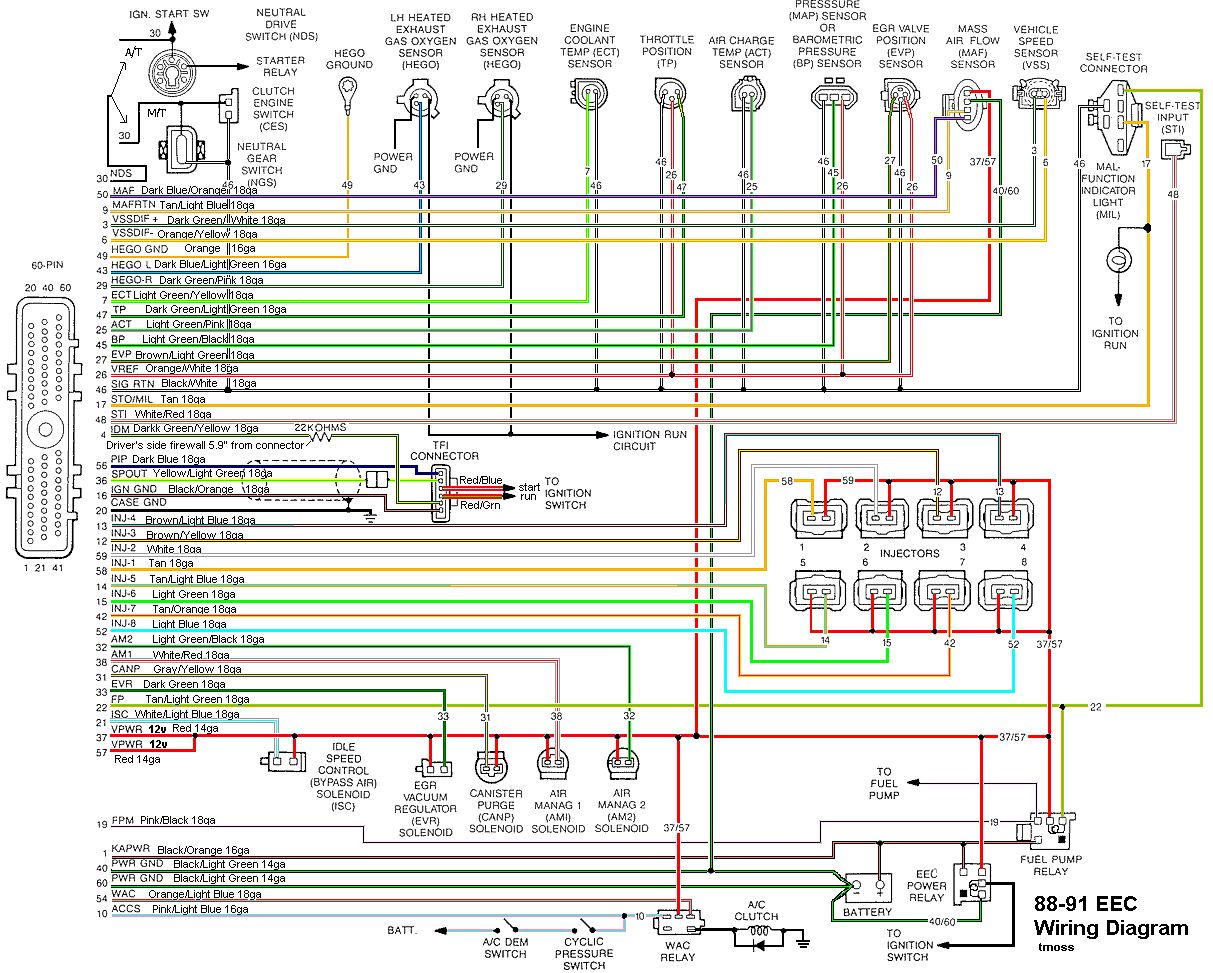

Diagrams courtesy of Tmoss & Stang&2birds

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

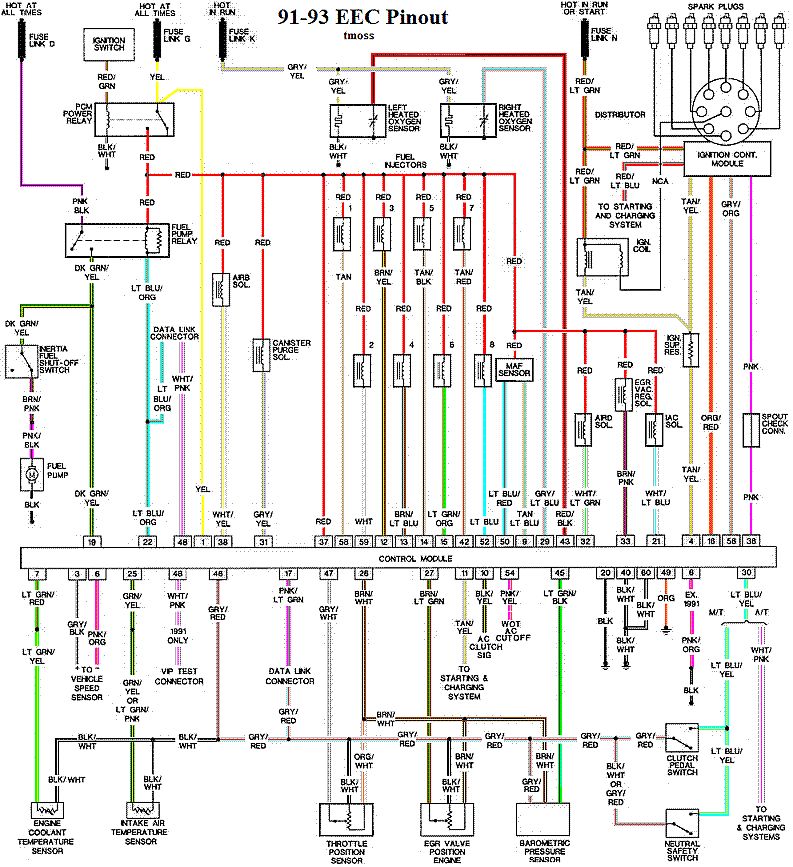

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

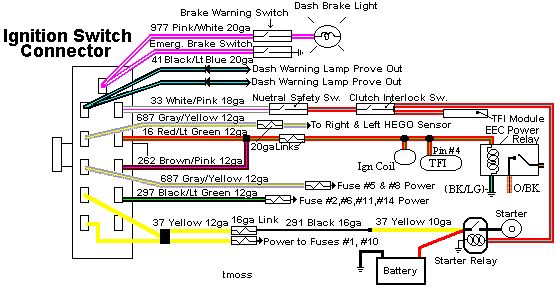

Ignition switch wiring

Fuel, alternator, A/C and ignition wiring

O2 sensor wiring harness

Vacuum diagram 89-93 Mustangs

HVAC vacuum diagram

TFI module differences & pin out

Fuse box layout

87-92 power window wiring

93 power window wiring

T5 Cutaway showing T5 internal parts

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

Code 15 or 511 - No Keep Alive Memory power to PCM pin 1 or bad PCM (Memory Test Failure).

Revised 4-Jan-2019 to add removing any custom tuning chip for minimum configuration testing.

Code 15 may come up if the battery is disconnected or the computer has been disconnected. If this is not what you have done, be sure to do the voltage tests below.

The voltage to the Keep Alive Memory (KAM) is missing (wiring problem) or the KAM is bad. The KAM holds all of the settings that the computer "learns" as it operates and all the stored error codes that are generated as a result of something malfunctioning while the engine is running. Use a voltmeter to check the voltage to the pin 1 on the computer - you should always have 12 volts. No constant 12 volts = bad wiring. If you do always have the 12 volts, then the KAM may be bad and the computer is faulty. Read on further to make this determination, since there are some exceptions.

Clearing the codes by pressing a button on the scan tool or disconnecting the test jumper used to start the code dump does not erase the “learned settings”. Disconnecting the computer from the wiring harness or disconnecting the battery (either power or ground cable) will erase the “learned settings” If the computer has to "relearn" all the optimum settings every time it powers up, the initial 15-30 minutes of operation may exhibit surges, poor low speed performance, and rough idle.

Note that some aftermarket chips will cause code 15 to set. Disconnect the battery and remove the chip, reconnect the battery and retest. If you have a custom burned chip using the data gathered from a dyno session, this may not be advisable since it may drastically alter the fuel/air and timing tables.

Disconnect the battery negative terminal for the next step.

Remove the passenger side kick panel and examine the computer. It is held in place by a diagonal plastic strap and 2 screws in the strap. The end of the computer opposite the wiring harness may have an accessory PC board with a big chip in a socket. That chip is a custom tune to accommodate the mods that affect fuel /air mixture, ignition timing and emissions equipment. If it is present, remove it and see if the engine runs any better. Remember that the car will need to be driven at highway speeds for at least 15-20 minutes in order for the computer to relearn the adaptive settings.

For stock engines or engines with minor modifications (OEM cylinder heads, stock 19 LB injectors, no NO2 or pressurized induction).

Before replacing the computer, remove the battery ground cable for about 20 minutes. This will clear all the codes and “learned settings”. Retest after several days of running. If the 15 code is gone, then don't worry about it. If it is still there, then you get to do some troubleshooting.

See the following website for some help from Tmoss (diagram designer) & Stang&2

Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/

Diagram courtesy of Tmoss & Stang&2birds

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Code 96 causes & tests 91-93 models. – KOEO- Fuel pump monitor circuit shows no power - Fuel pump relay or battery power feed was open - Power / Fuel Pump Circuits. The fuel pump circuit lost power at one time or another.

Revised 11 Oct 2021 to add troubleshooting tip to distinguish a fuel pump relay problem from an ignition switch problem.

The code 96 may be intermittent, so it is difficult to pin down the exact source of the problem.

Clear the codes by disconnecting the battery and turning on the headlights for about 5 minutes before reconnecting the battery. This will clear any remaining codes. Drive the car for several days and dump the codes again. In many cases, this clears the 96 code.

Look for a failing fuel pump relay, bad connections or broken wiring. On 91 model cars, the fuel pump relay is under the driver’s seat. The fuel pump relay is located under the Mass Air Meter on Fox bodied stangs built after 91. It can be confused with the A/C Wide Open Throttle relay which is in the same area. Use the wire colors as shown in the diagram below to identify which relay is the fuel pump relay.

This code is often intermittent; the only clue is that the engine shuts off or stumbles while you are driving. This limits your ability to troubleshoot the problem when it happens, so you have to rely on the code dump to clue you in on what’s happening.

The radio, heater or A/C are not affected. If the radio, heater or A/C turn off at the same time the engine stumbles, look for a failing ignition switch.

Diagram of the fuel pump wiring for 91-93 cars.

Look for power at the fuel pump - the fuel pump has a connector at the rear of the car with a pink/black wire and a black wire that goes to the fuel pump. The pink/black wire should be hot when the test connector is jumpered to the test position. To trick the fuel pump into running, find the ECC test connector and jump the connector in the lower RH corner to ground. No voltage when jumpered, check the fuel pump relay and fuse links.

Power feed: Look for 12 volts at the pink/black wire (power source for fuel pump relay). No voltage or low voltage, bad fuse link, bad wiring, or connections. Remember that on 92 or later models the fuel pump relay is located under the Mass Air meter. Watch out for the WOT A/C control relay on these cars, as it is located in the same place and can easily be mistaken for the fuel pump relay.

Relay: Turn on the key and jumper the ECC test connector as previously described. Look for 12 volts at the dark green\yellow wire (relay controlled power for the fuel pump). No voltage there means that the relay has failed, or there is a broken wire in the relay control circuit.

Be sure to closely check the condition of the relay, wiring & socket for corrosion and damage.

91-93 Models:

Using the diagram, check the dark green/yellow wire from the fuel pump relay: you should see 12 volts or so. If not the relay has failed or is intermittent. Check the inertia switch: on a hatch it is on the driver’s side by the taillight. Look for a black rubber plug that pops out: if you don't find it, then loosen up the plastic trim. Check for voltage on both sides of the switch. If there is voltage on both sides, then check the Pink/black wire on the fuel pump relay: it is the power feed to the fuel pump. Good voltage there, then the fuel pump is the likely culprit since it is getting power. No voltage there, check the Pink/black wire, it is the power feed to the fuel pump relay & has a fuse link in it. Good voltage there & at the dark green/yellow wire, swap the relay.

All testing is done with the ignition switch in the Run position. Do not forget this crucial step.

The pink/black wire should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the fuse link for the fuel pump has opened up.

With the test jumper in place the green/yellow wire should be the same voltage as the pink/black wire +/- 0.25 volt.

If not, look at the red wire: should have the same voltage as the battery positive terminal +/- 0.25 volt.

If not, then check the yellow wire on the EEC relay located on top of the computer. This one is hard to get to. It should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the fuse link for the computer has opened up.

If the red wire does not have the same voltage as the battery positive terminal +/- 0.25 volt and the yellow wire on the EEC relay does, then check the red/green wire on the EEC relay. It should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the ignition switch is defective or the fuse link in the ignition wiring harness has opened up, or the EEC relay is defective.

All testing is done with the ignition switch in the Run position. Do not forget this crucial step.

The pink/black wire s should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the fuse link for the fuel pump has opened up.

With the test jumper in place the green/yellow wire should be the same voltage as the pink/black wire +/- 0.25 volt.

If not, look at the red wire: should have the same voltage as the battery positive terminal +/- 0.25 volt.

If not, then check the yellow wire on the EEC relay located on top of the computer. This one is hard to get to. It should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the fuse link for the computer has opened up.

If the red wire does not have the same voltage as the battery positive terminal +/- 0.25 volt and the yellow wire on the EEC relay does, then check the red/green wire on the EEC relay. It should have the same voltage as the battery positive terminal +/- 0.25 volt. If not, then the ignition switch is defective or the fuse link in the ignition wiring harness has opened up, or the EEC relay is defective.

Diagram courtesy of Tmoss & Stang&2birds