I cross threaded the threads for one of the bolts that holds the throttle cable bracket on my 92 GT. They make a m8x1.25 thread repair kit which is the size I need. However the size of the new threads/coil is about .49 inches, while the bolt is about .75 inches. Do I need to get a coil that is the same length or does it not matter.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fox Question about how to use a thread repairer

- Thread starter AnthonyA1234

- Start date

-

Sponsors (?)

Ok sounds good

I’m going to try using just a tap first to see if I can clean up/fix the threads. If that doesn’t work I’ll put a coil in there.

I’m going to try using just a tap first to see if I can clean up/fix the threads. If that doesn’t work I’ll put a coil in there.

This should help:

Youtube University

Youtube University

You guys think the tap will work? I was reading up on that and I ordered a taper tap which I’ll use first and then I ordered a bottoming tap to finish it. I’m hoping that’s all I need to fix these threads.

Attachments

Generally, you get the entire kit unless you already possess the tools.You guys think the tap will work? I was reading up on that and I ordered a taper tap which I’ll use first and then I ordered a bottoming tap to finish it. I’m hoping that’s all I need to fix these threads.

A kit generally includes:

The size [Helicoil]/insert that you require

The appropriate size drill bit

The appropriate size Tap

The appropriately sized Insert Seating Tool

Some goo

Instructions

There's nothing wrong with getting them all separate but the kit guarantees that you have what you need for the size.

No I’m saying just using a tap to rethread the hole. No coil. A buddy of mine said to try that first if the threads aren’t too bad.Generally, you get the entire kit unless you already possess the tools.

A kit generally includes:

The size [Helicoil]/insert that you require

The appropriate size drill bit

The appropriate size Tap

The appropriately sized Insert Seating Tool

Some goo

Instructions

There's nothing wrong with getting them all separate but the kit guarantees that you have what you need for the size.

Ah.... I see what you're saying. Just clean out the hole really well and tape off anything the shavings could get into. You will know if it needs more once you get your eyeballs on the rethreaded hole.No I’m saying just using a tap to rethread the hole. No coil. A buddy of mine said to try that first if the threads aren’t too bad.

The .5in coil will be plenty for that size hole.

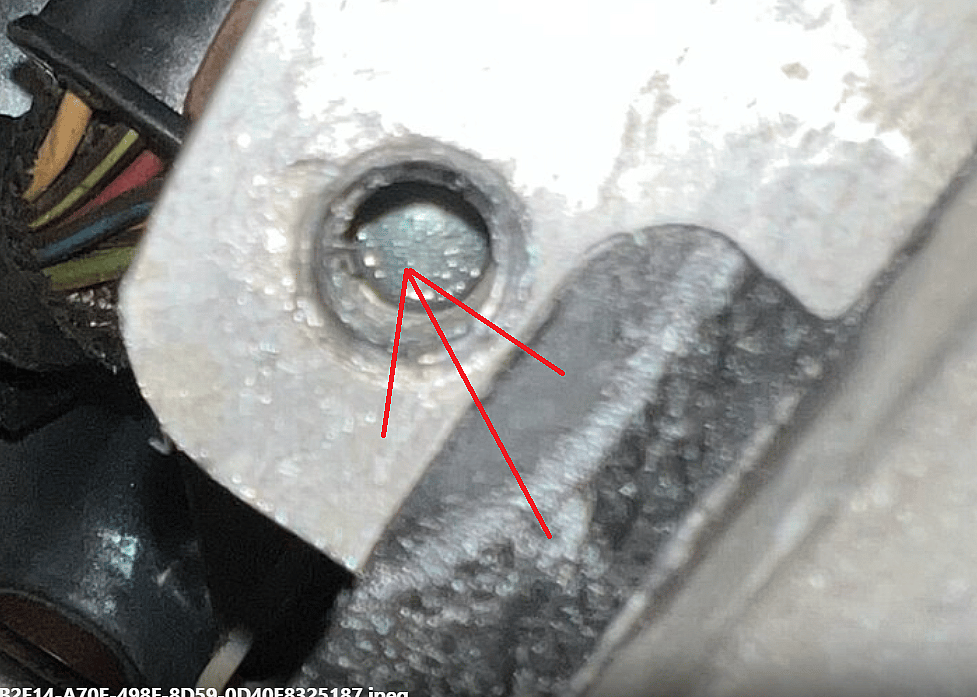

The pictures aren’t great, but it almost looks like there’s nothing left of the threads in that plate. I would’ve probably just gone straight in with a heli coil so it’ll be good in the future.

The pictures aren’t great, but it almost looks like there’s nothing left of the threads in that plate. I would’ve probably just gone straight in with a heli coil so it’ll be good in the future.

Could you send me an example of a thread chaser that would work? Whenever I look that up a whole bunch of different things come up.

Just make it easy and go pick up a m8x1.25 plug tap. It’s just gonna be used to clean up the first thread for the ones that are left.Could you send me an example of a thread chaser that would work? Whenever I look that up a whole bunch of different things come up.

Or go get a longer bolt and just try that. Might not even need the threads cleaned up.

Ok sounds good. Yesterday I ordered a set of m8x1.25 taps. It comes with a taper, plug, and bottoming tap. You think I should just use the plug or would I benefit from using one of the other ones as well.Just make it easy and go pick up a m8x1.25 plug tap. It’s just gonna be used to clean up the first thread for the ones that are left.

Or go get a longer bolt and just try that. Might not even need the threads cleaned up.

From that, you would use the [Tap] and carefully thread it into the hole...Ok sounds good. Yesterday I ordered a set of m8x1.25 taps. It comes with a taper, plug, and bottoming tap. You think I should just use the plug or would I benefit from using one of the other ones as well.

back it out

clean it

thread it back in some more

back it out

clean it

rinse and repeat

A good air compressor for cleaning it out between passes makes it all easy. A little bit of oil on the tap and on the threads will help too. Clean the tap between passes as well.

Get a quality replacement bolt and ensure that it's the same grade as its sister bolts. ARP comes to mind.

Update on how it ended up going:

Put the tap in and made a fresh new set of threads. I screwed the bolt in and it did the same thing it did before. It goes in about 60% of the way and then stops. I also went to deep with the tap and popped up the powder coat on my intake of the back side of the hole. You cant see it at all but I’m hoping that doesn’t compromise the rest of the powder coat and make it start popping up. I think I’m just gonna put some washers on it to fill the gap between the bolt and the intake and call it a day.

Put the tap in and made a fresh new set of threads. I screwed the bolt in and it did the same thing it did before. It goes in about 60% of the way and then stops. I also went to deep with the tap and popped up the powder coat on my intake of the back side of the hole. You cant see it at all but I’m hoping that doesn’t compromise the rest of the powder coat and make it start popping up. I think I’m just gonna put some washers on it to fill the gap between the bolt and the intake and call it a day.

Can you use a stud in that location instead of a bolt?

My concern with your washer method is that you're going to be grabbing even fewer threads than before.

Leaking intakes uh... [suck]

My concern with your washer method is that you're going to be grabbing even fewer threads than before.

Leaking intakes uh... [suck]

That’s not supposed to be a blind hole? I’m wondering if the powder coat people covered that side with a wrapper and I never took it off and maybe that’s what I punctured.Looking back at your images....

Is that part a [bolt] stuck down in that hole???

What's this?

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 9

- Views

- 687

- Sticky

- Replies

- 33

- Views

- 13K

- Replies

- 11

- Views

- 2K