Looks good, you get the tail pipes on clearance? Noticed Holley trying to move some product lol.... https://www.holley.com/products/clearance_parts/parts/15814

I got the different tailpipes. The SS version. 815814. Couldn’t find any deals on those.

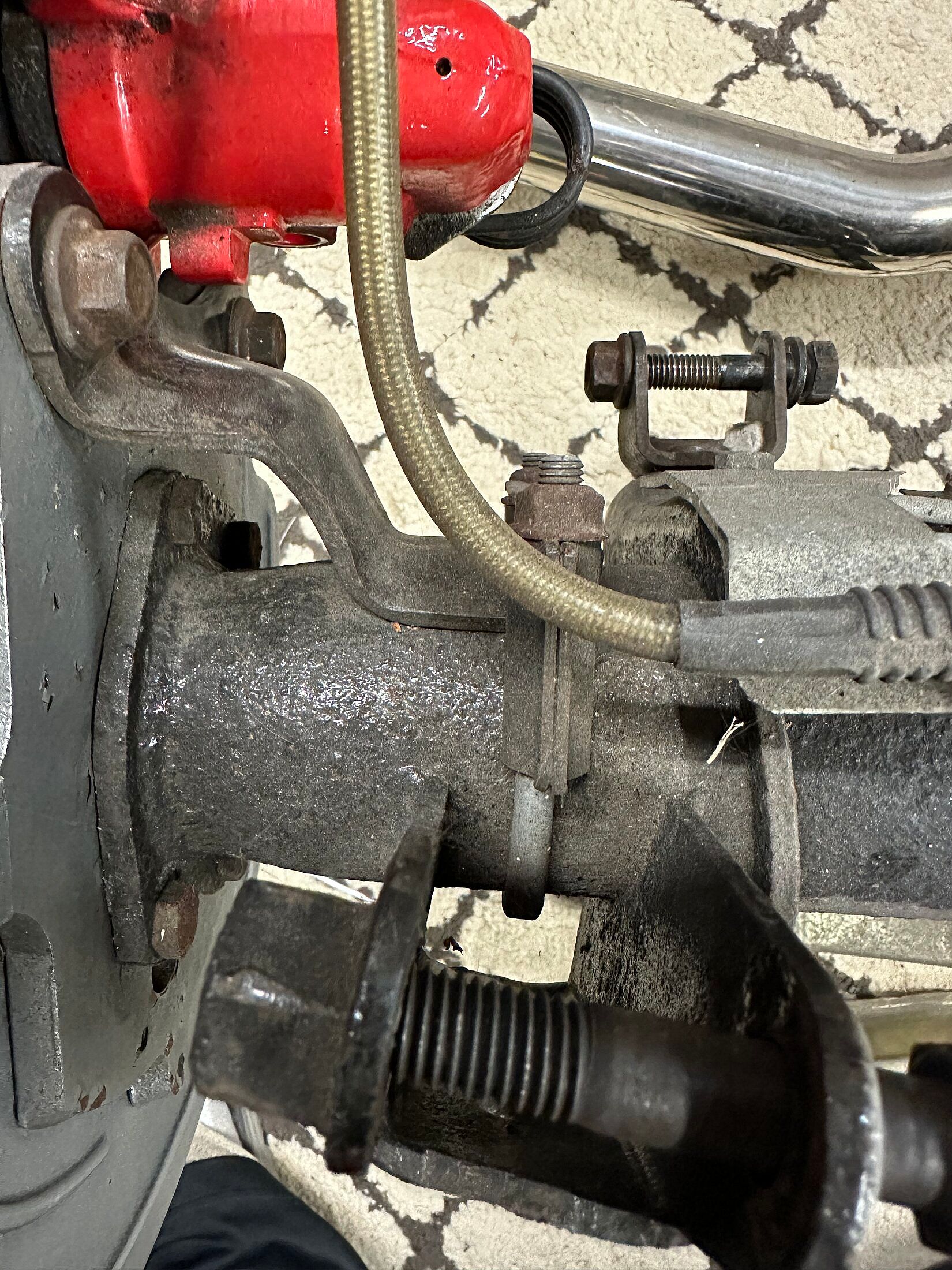

Just a heads up on the panhard bar you have in the corner. When mine went in I had to cut the tail pipes loose and make some mods to get all of it to clear.

Already test fit with the previous exhaust. Fit perfectly with the flowmaster tailpipes, which is why I chose to buy another set of flowmaster pipes.