Well, I think I got my answer.

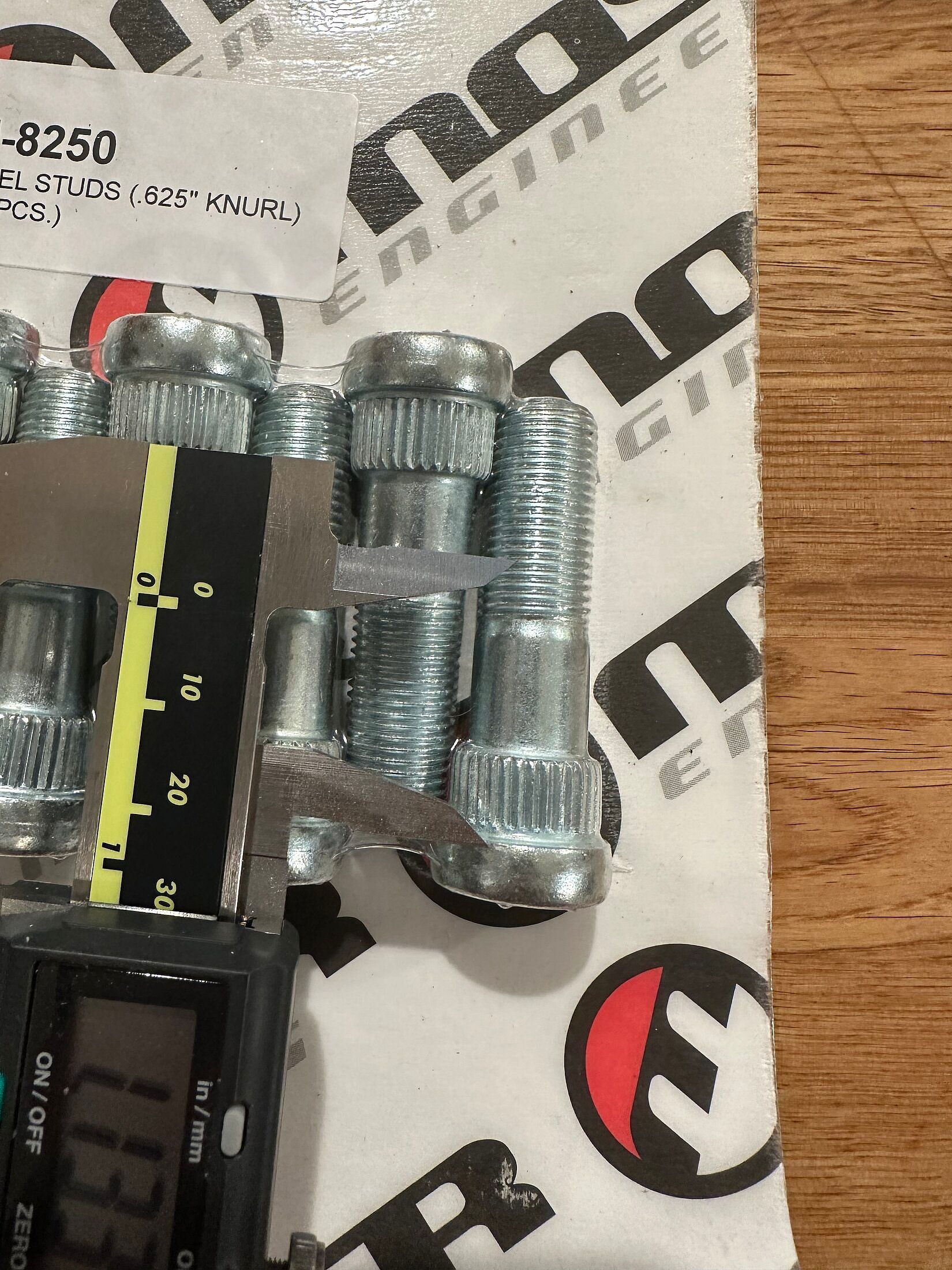

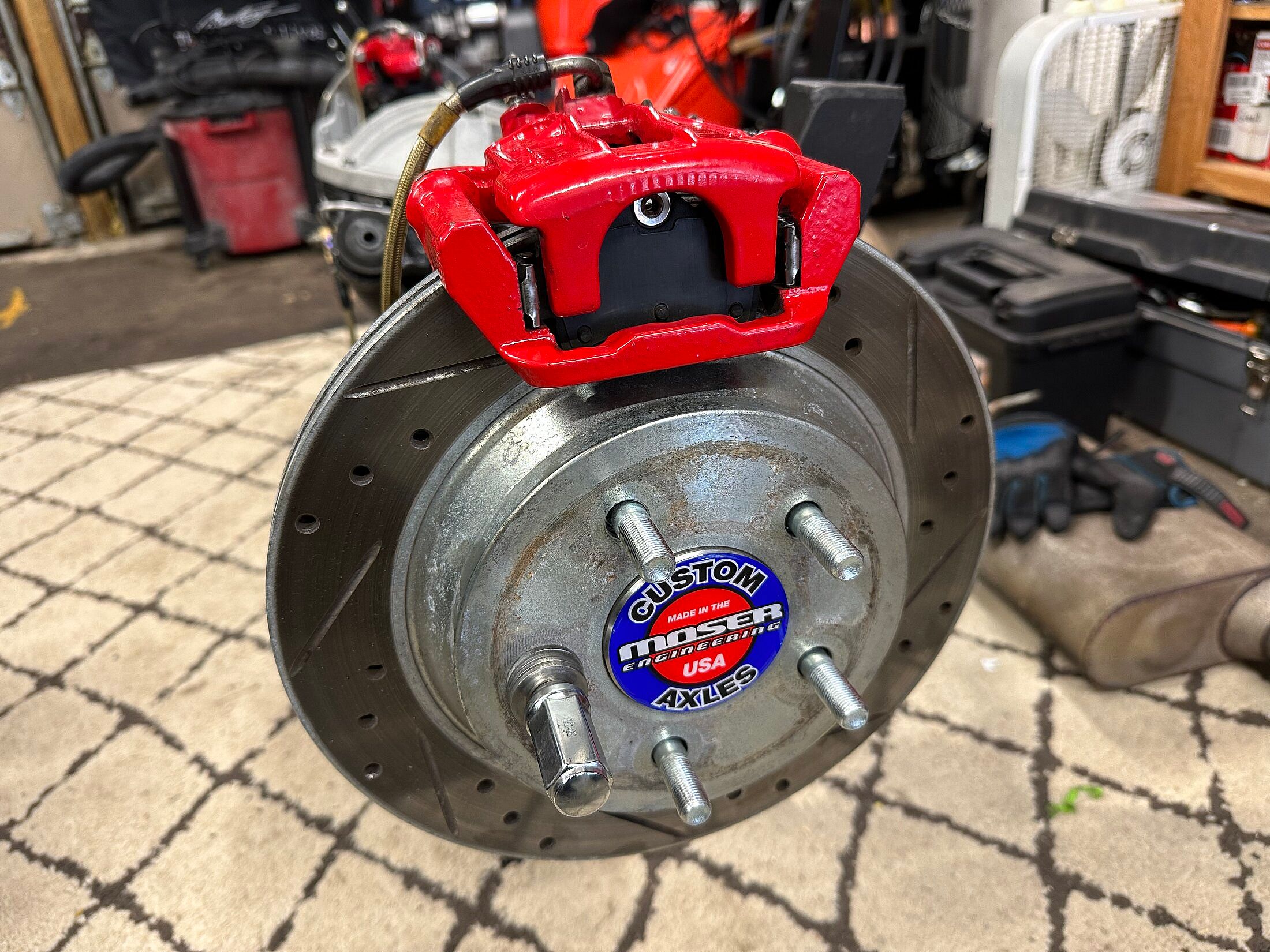

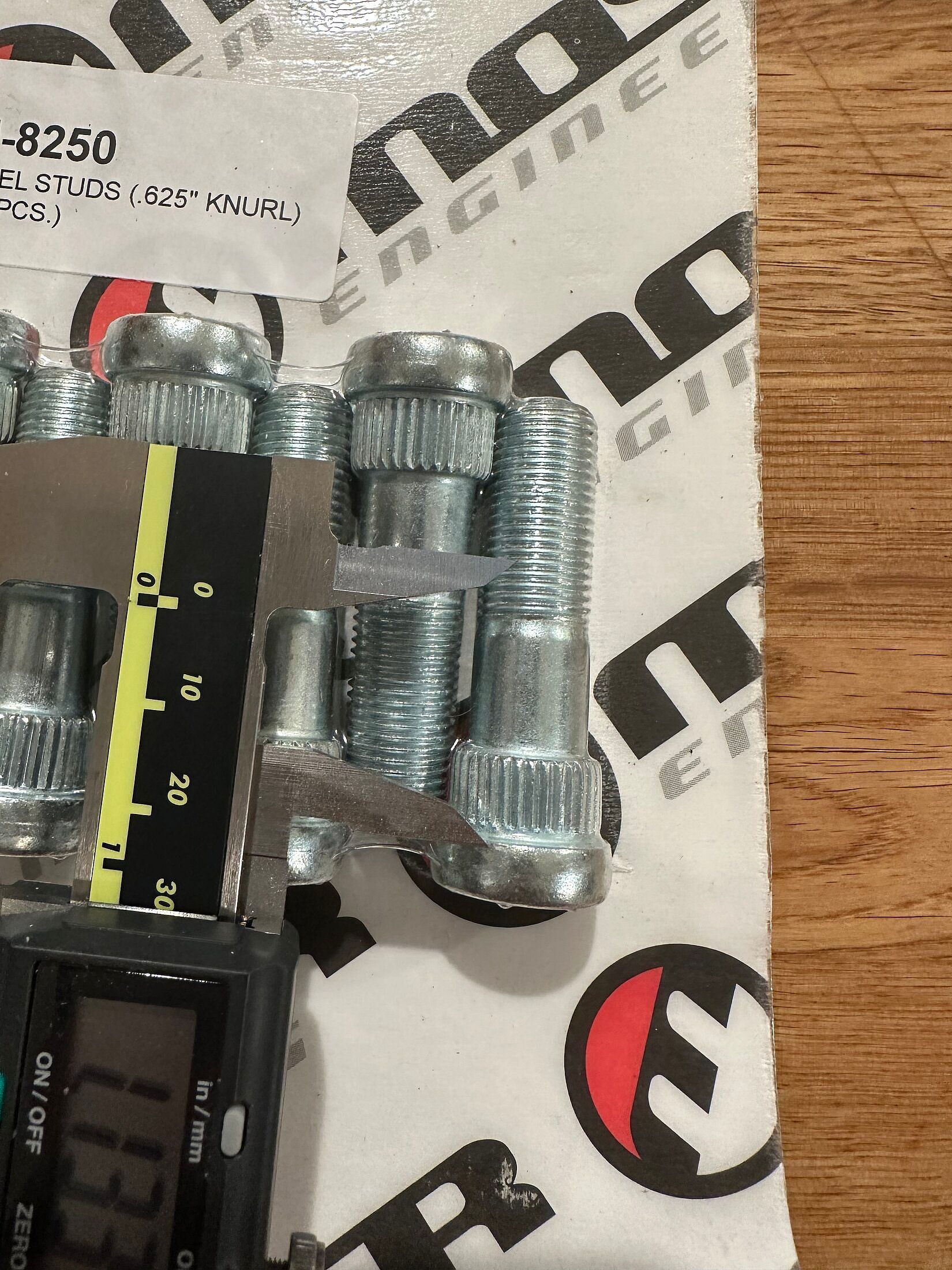

Flange is .400 thick. Rotor hat is .233 thick. And 0.500 from mounting face of wheel to start of acorn taper.

So 1.133” which puts me here. I think I’ll run the Moroso and return the Dorman

Flange is .400 thick. Rotor hat is .233 thick. And 0.500 from mounting face of wheel to start of acorn taper.

So 1.133” which puts me here. I think I’ll run the Moroso and return the Dorman