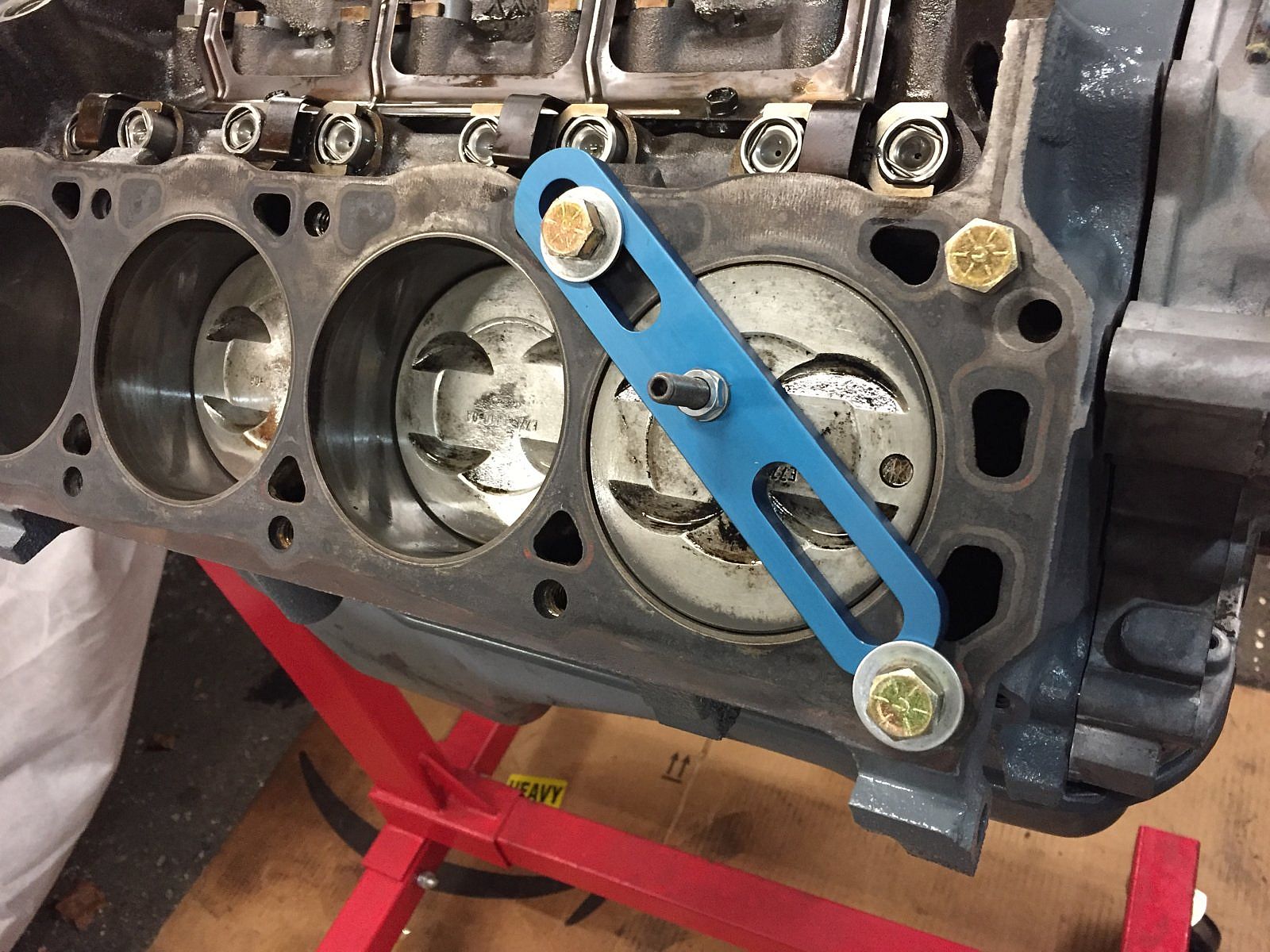

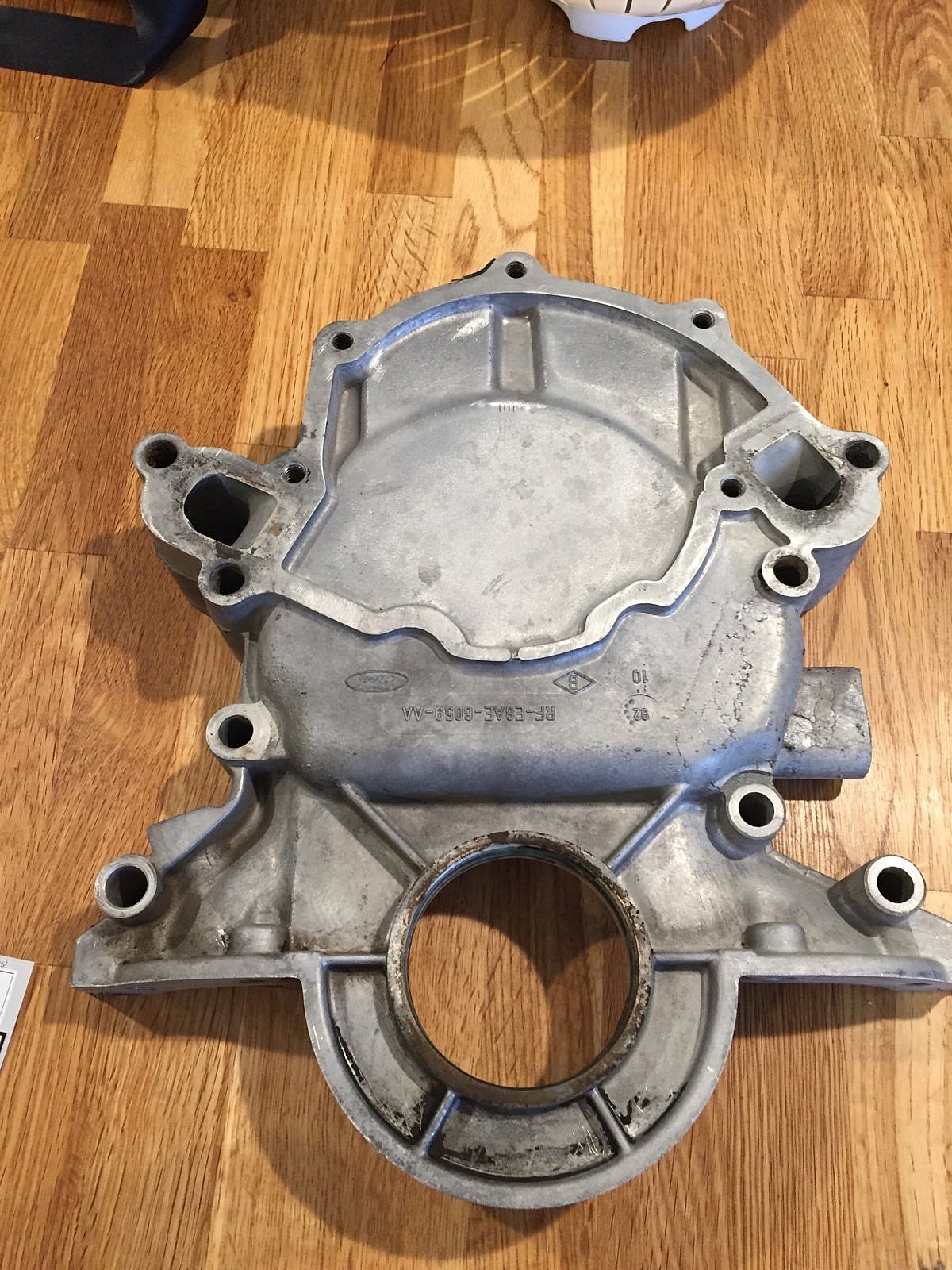

A little progress last night before bed. Working on removing the caked on, factory original timing cover gasket. This took a while. Consisted of applying gasket remover, waiting the necessary 30 mins for it to soften the gasket, and then scraping it off. Clean off and repeat a few times. I might do it one more time tonight.

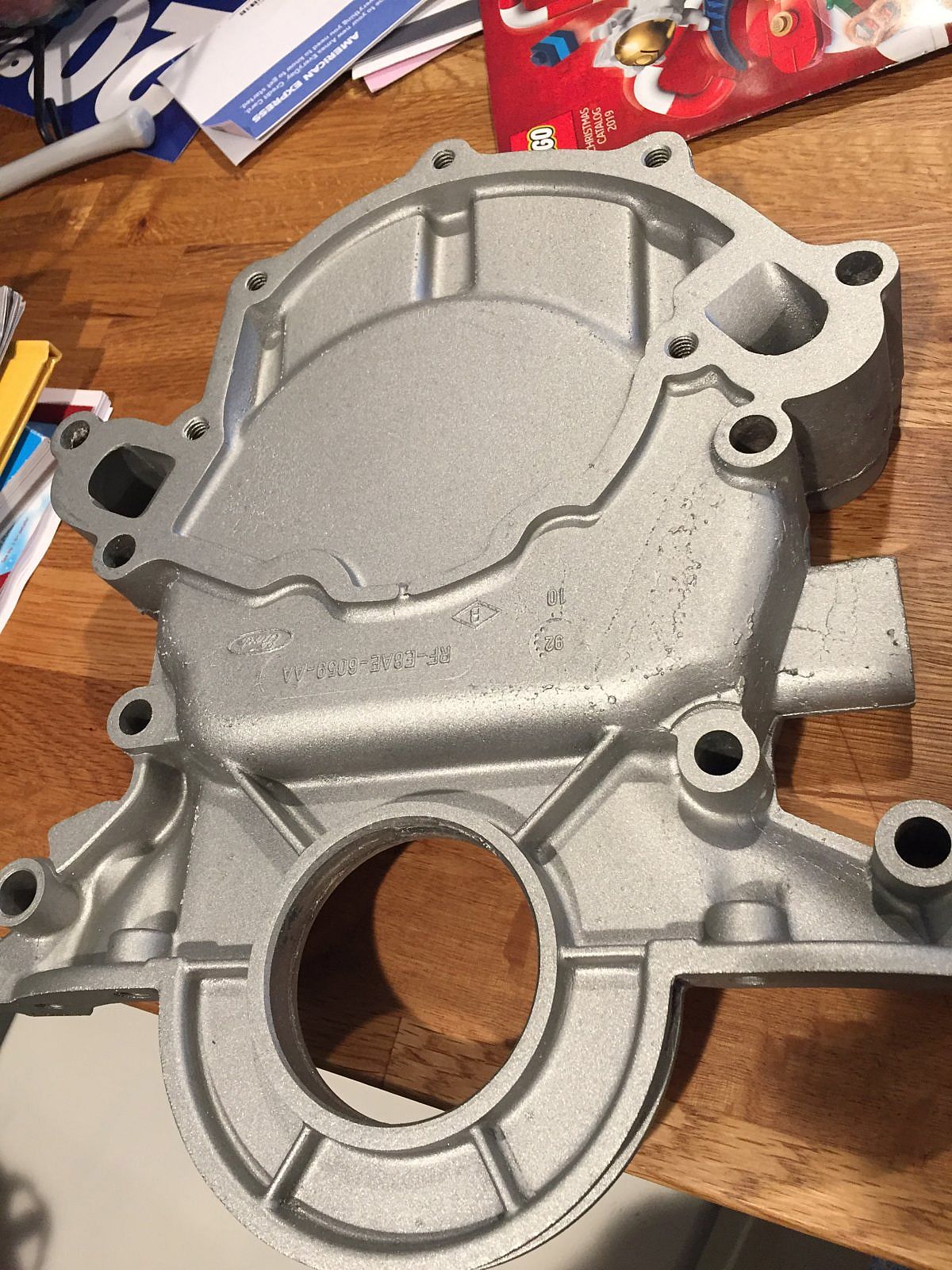

Replacement core plug is installed.

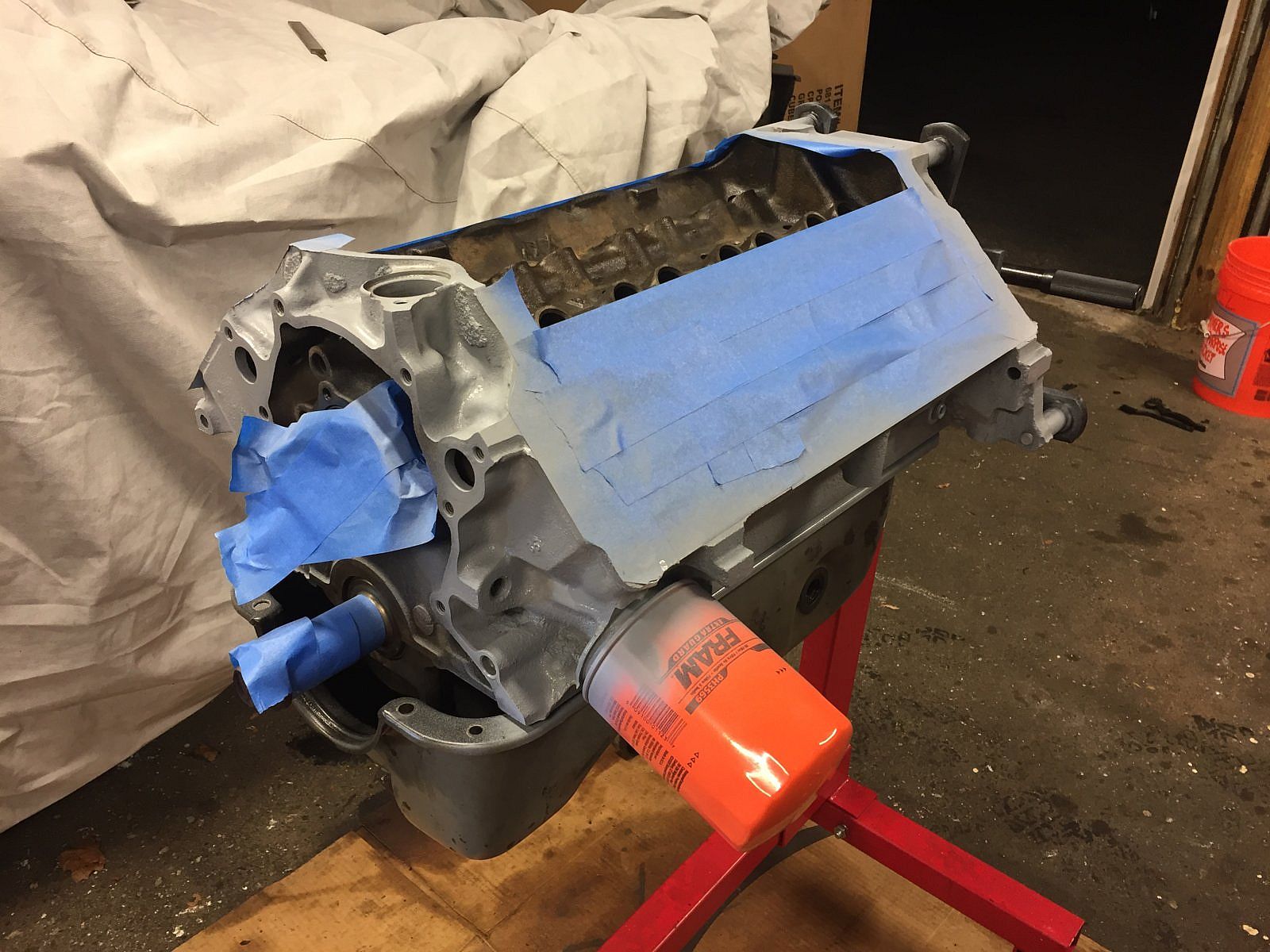

Getting ready to wash block down with soap, and begin masking for paint.

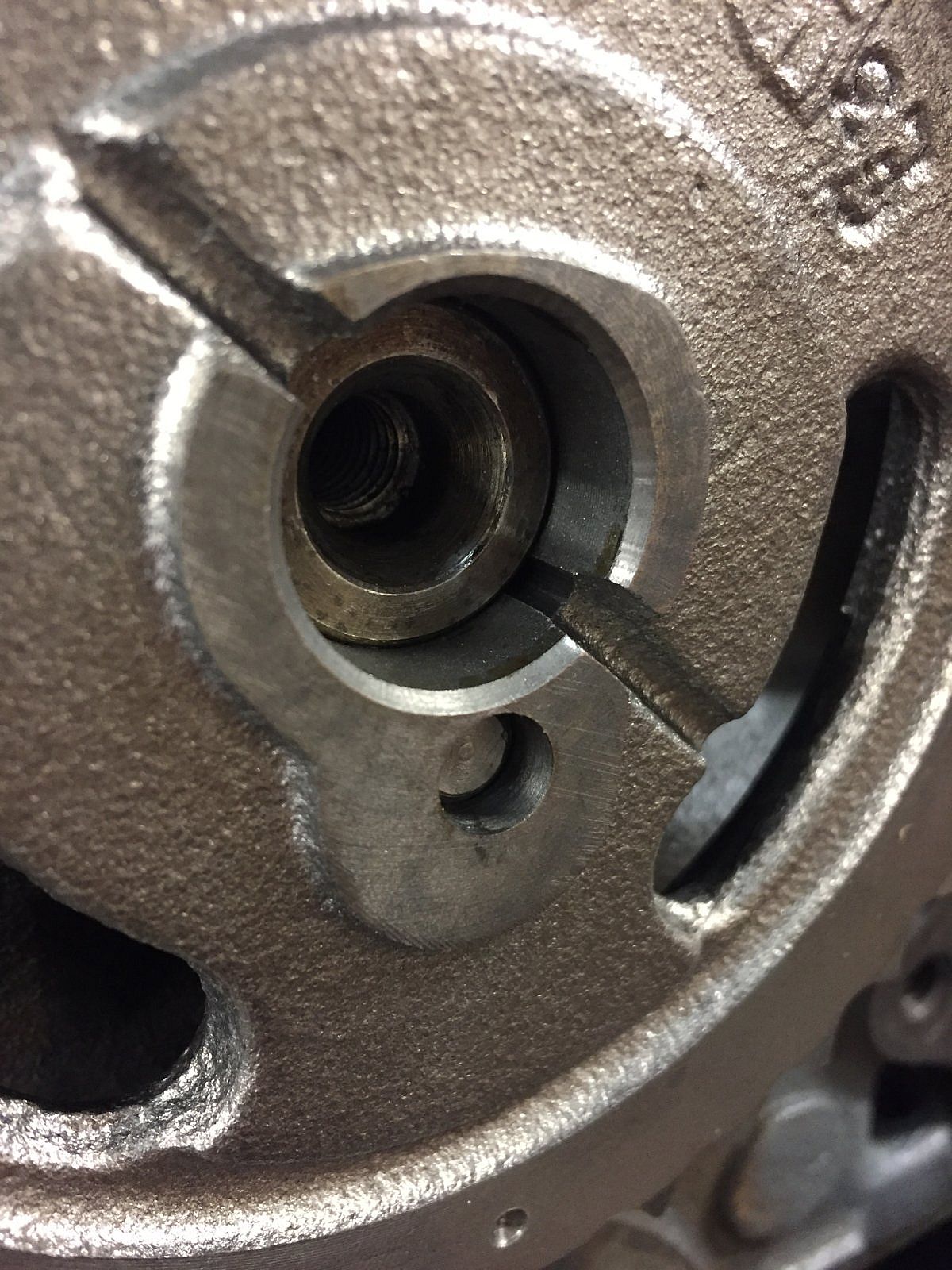

I still need to chase out all these threaded holes as well. Just need to figure out the sizes I need first. The original bolts were a bit rusty, so they need to be replaced as well.

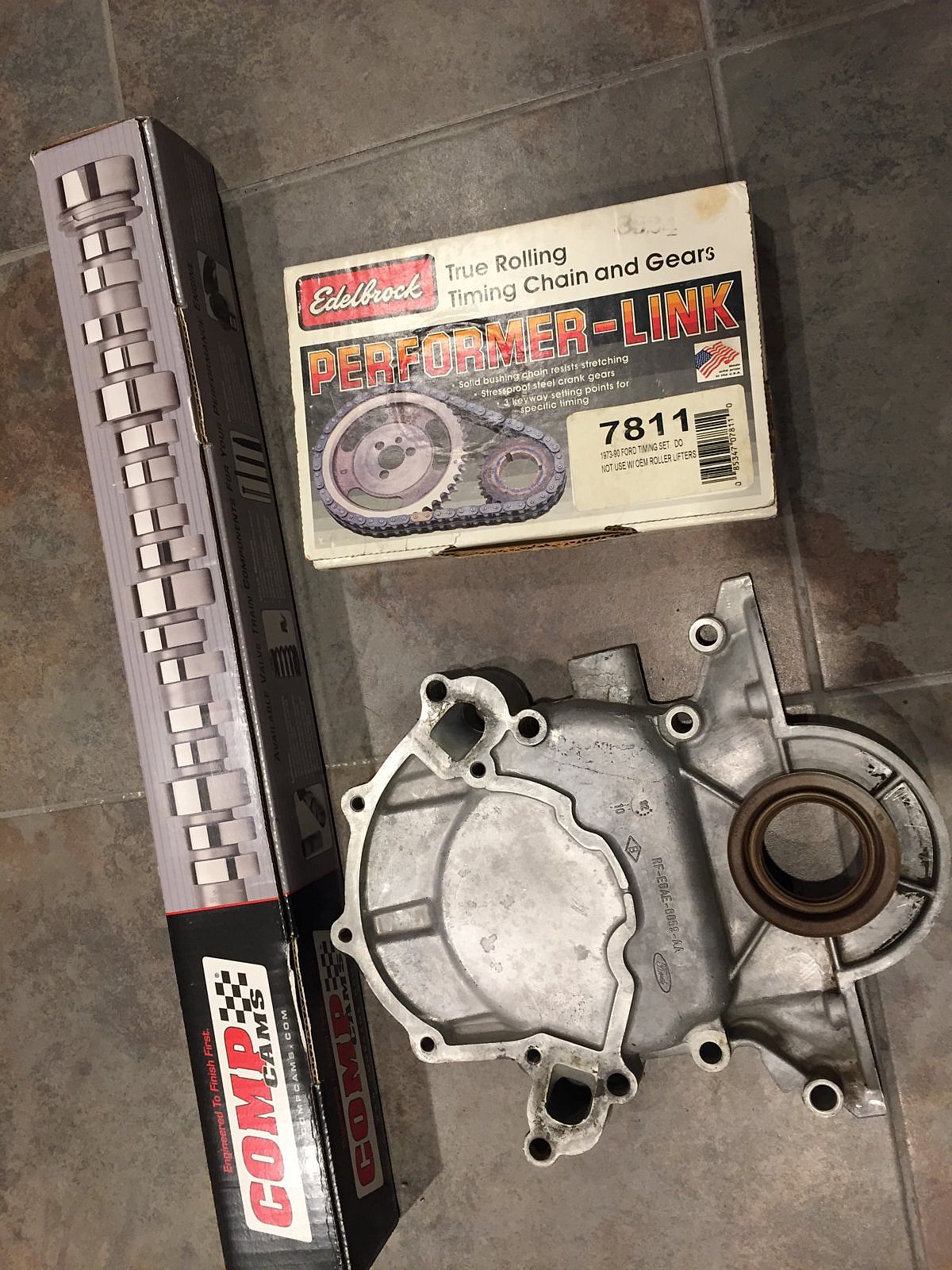

Nickel and dime

Replacement core plug is installed.

Getting ready to wash block down with soap, and begin masking for paint.

I still need to chase out all these threaded holes as well. Just need to figure out the sizes I need first. The original bolts were a bit rusty, so they need to be replaced as well.

Nickel and dime