Shouldn't you say 'timing impaired curve'?timing retard curve?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Project Silver Fox - 3rd time’s a charm

- Thread starter 96pushrod

- Start date

-

Sponsors (?)

93 octane pump, 11r, 10.9:1What fuel, cylinder head, comp ratio.

What's your timing value at 100kpa?

What is your timing retard curve?

29* @100kpa

Dialed back 10* @170

Essentially just pulling a degree per pound of boost, pretty much the same retard I pulled when spraying with the 78 pill I used to do.

Next week I’m gonna put a set of plugs in and see where the mark is at on the strap. I can tell you the clutch won’t take anymore power, so if anything I’ll pull a little out.

The 11R heads do not like timing whatsoever. Excellent chamber design.93 octane pump, 11r, 10.9:1

29* @100kpa

Dialed back 10* @170

Essentially just pulling a degree per pound of boost, pretty much the same retard I pulled when spraying with the 78 pill I used to do.

Next week I’m gonna put a set of plugs in and see where the mark is at on the strap. I can tell you the clutch won’t take anymore power, so if anything I’ll pull a little out.

I would actually pull a degree out of it at 100kpa. I have had cars pick up 2-5mph trap speed by dropping some timing on that head.

I’ve had the car on the dyno and 29* was the sweet spot.The 11R heads do not like timing whatsoever. Excellent chamber design.

I would actually pull a degree out of it at 100kpa. I have had cars pick up 2-5mph trap speed by dropping some timing on that head.

I always pull a degree from the dyno timing. It's not the same as a fully heat soaked street driven car doing pulls on the highway.I’ve had the car on the dyno and 29* was the sweet spot.

But if your comfortable with it you do you.

That’s essentially what happened. When power began leveling off it was set to the beginning of that point. Car was also dyno’d in the middle of June in central Florida at temp with no fans on except the electric one on the car, so it was a pretty good recreation of what things might be like.I always pull a degree from the dyno timing. It's not the same as a fully heat soaked street driven car doing pulls on the highway.

But if your comfortable with it you do you.

Thanks man. I’m spending some time getting rid of the plastic cable tube for some split loom. Wish I had used this stuff from the startLooking clean

That's what I use, love it. My only coming is having to use cloth tape when I cover after putting on the connectors... I like to heat shrink the ends and splits but it don't always work out.

You used the tesa brand tape? That’s the brand we use in my hangar and it’s awesome. It’s tough to run heat shrink when the harness is already all routed.That's what I use, love it. My only coming is having to use cloth tape when I cover after putting on the connectors... I like to heat shrink the ends and splits but it don't always work out.

I have not, can I get that on amazon?

You used the tesa brand tape? That’s the brand we use in my hangar and it’s awesome. It’s tough to run heat shrink when the harness is already all routed.

5 Rolls Tesa's Most Advanced High Heat Harness Tape 51036 Mercedes, BMW, Audi, VW Amazon product ASIN B074YCG21ZView: https://www.amazon.com/dp/B074YCG21Z/ref=cm_sw_r_cp_api_i_1GASCDSEV8PTWMA04PDQ?_encoding=UTF8&psc=1I have not, can I get that on amazon?

This stuff here is great.

- Jul 7, 2005

- 1,563

- 1,197

- 164

Limited-time deal: Alex Tech 25ft - 3/8 inch Cord Protector Wire Loom Tubing Cable Sleeve Split Sleeving For USB Cable Power Cord Audio Video Cable – Protect Cat From Chewing Cords - Black Amazon product ASIN B07FW4M7Z8View: https://www.amazon.com/dp/B07FW4M7Z8/ref=cm_sw_r_cp_api_i_dl_1JSTXGEZ5NFTXAQDK7RD?_encoding=UTF8&psc=1Where did you get your new split loom from that your replacing the factory plastic?

This is what I use. Great for the money and they have tons of different diameters. 1/8 is perfect for injector and sensors wires that use 2 wires and for the rest it’s just a mixture of 1/4, 3/8, and 1/2in.

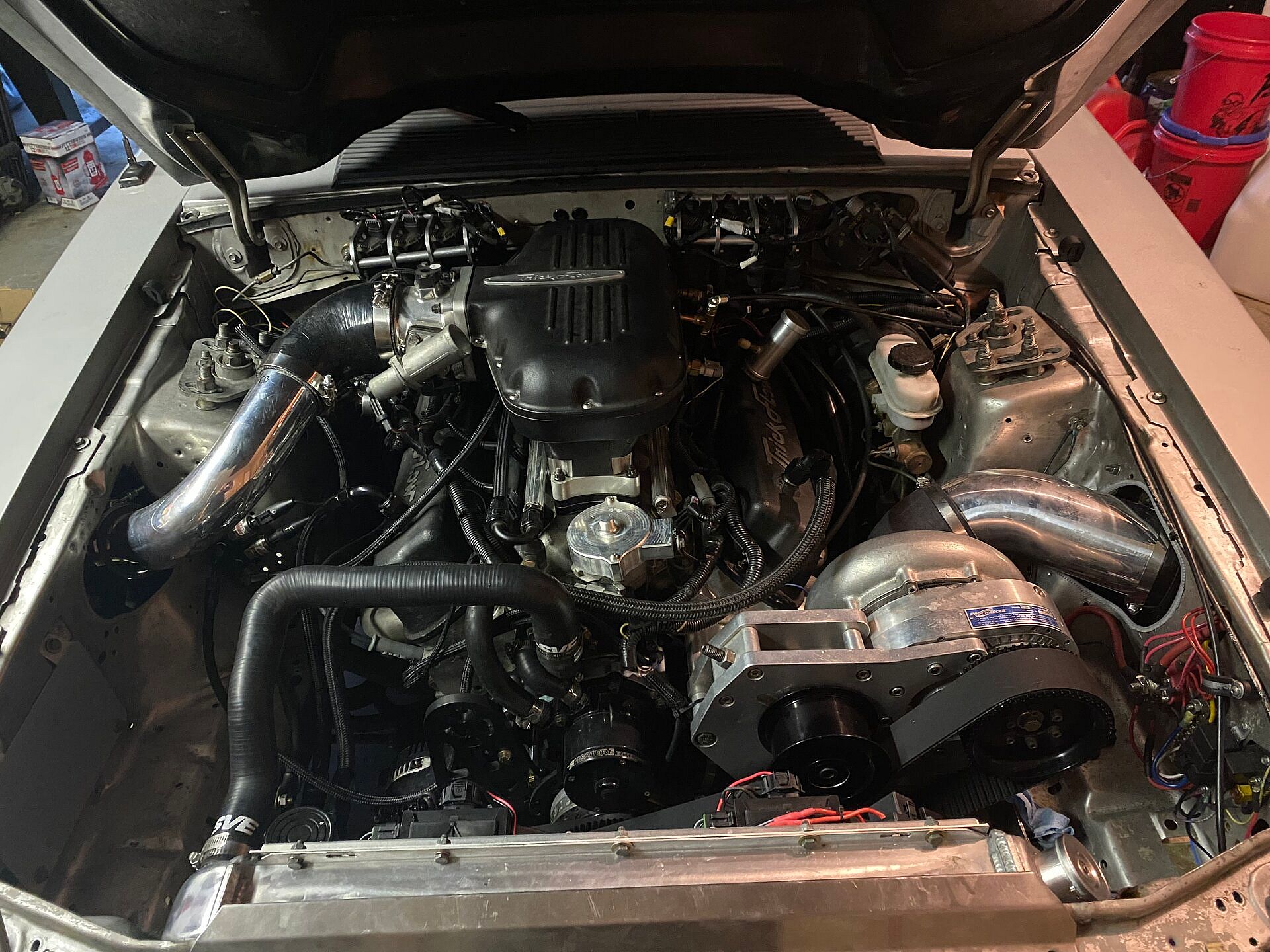

So the first couple weeks with the blower have been awesome. It makes good usable power down low, but really comes on once it sees a little rpm. No complaints.

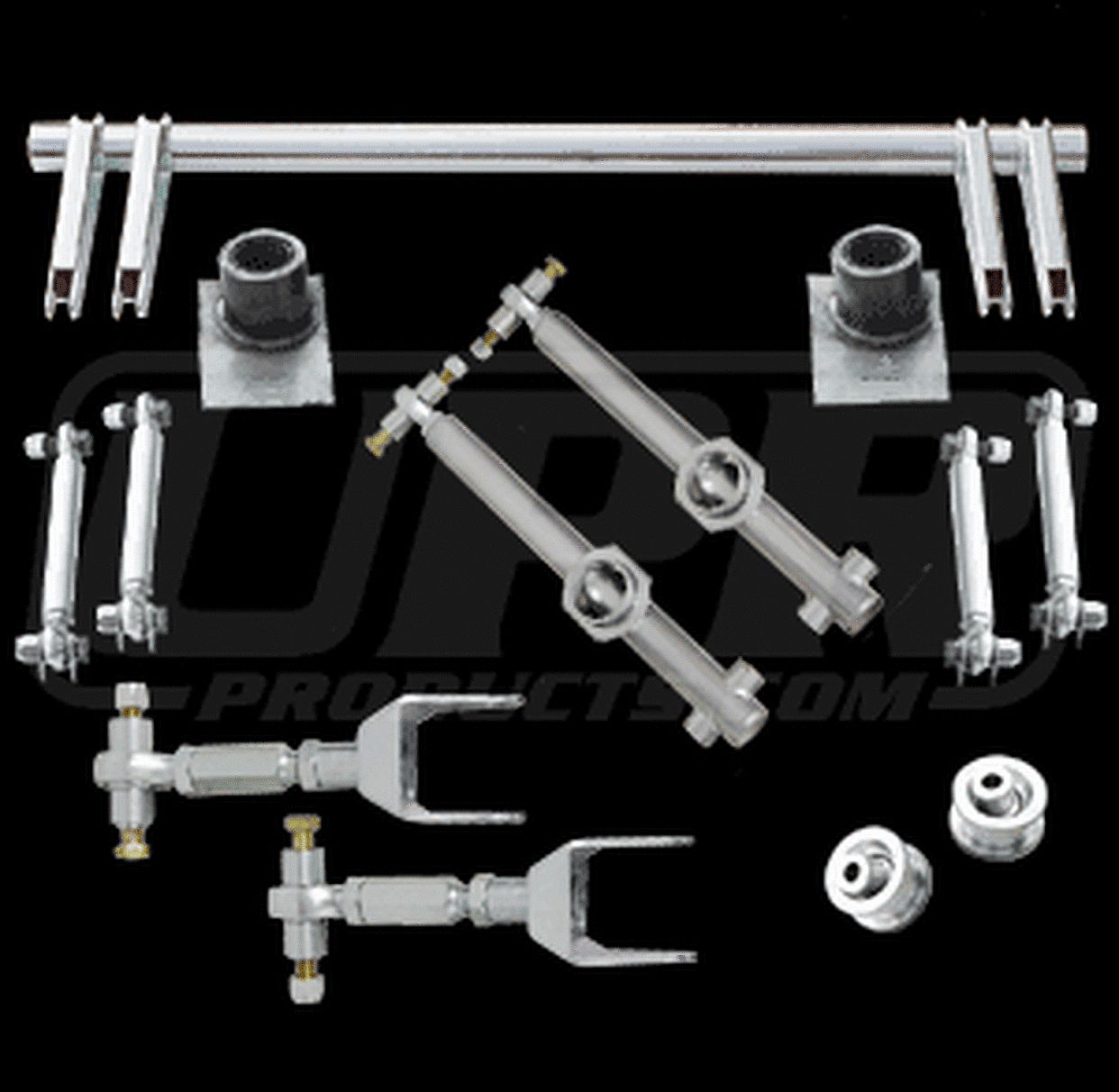

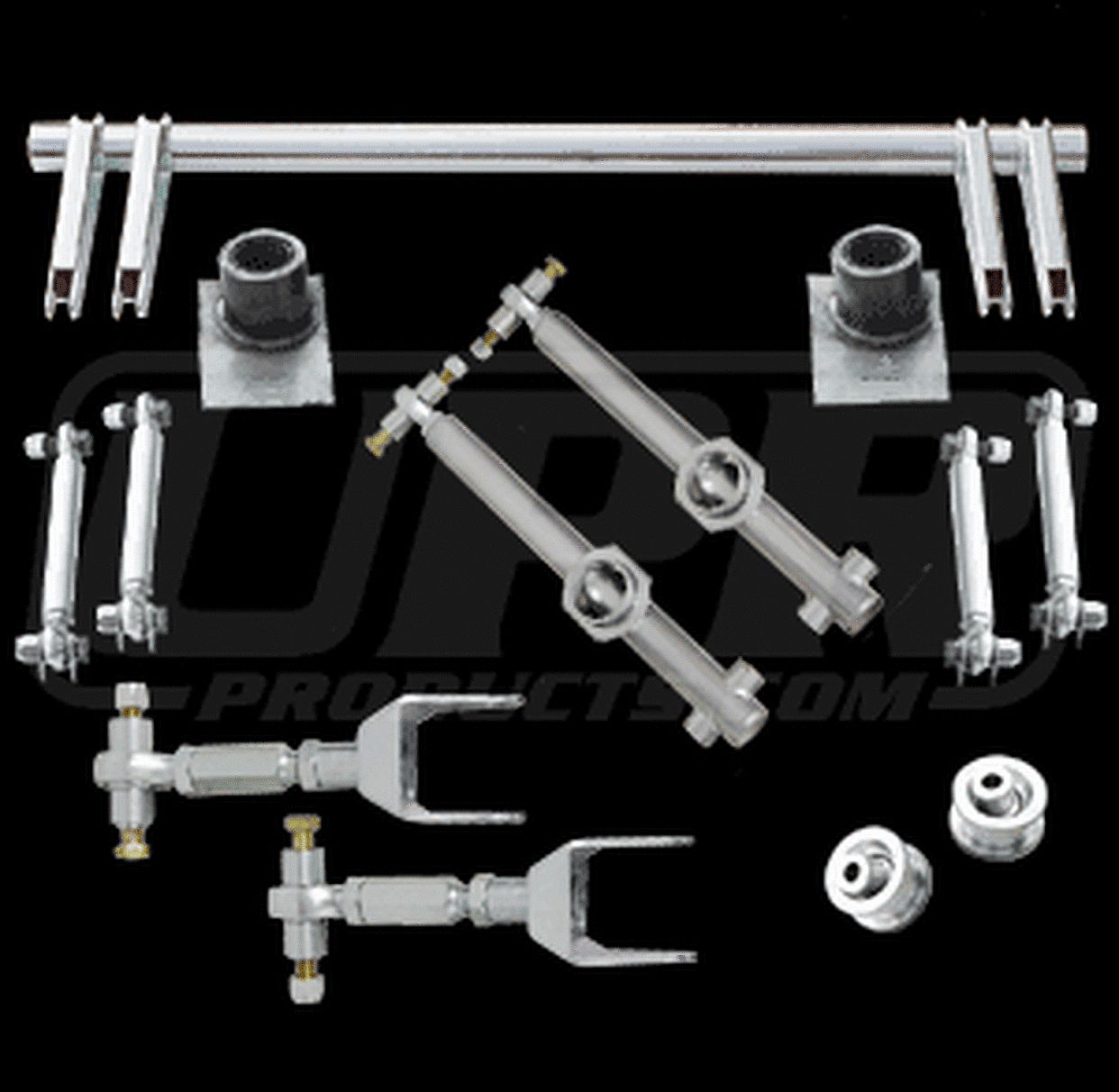

Next thing that needs addressed is the rear suspension. I’ve put it off for awhile, but it’s time. The other day I put the car on stands and took a measurement of the pinion angle; it was +1* up, which is terrible, especially for a poly bushing deal. I bought the upr pro extreme kit some time (probably close to 16 months) ago at a race over at sgmp and I’ll be installing it this week. Doubt I’ll get to the arb, but everything else should be easily doable in a day.

The arb is kind of overkill for what I’m doing, but that’s ok.

Next thing that needs addressed is the rear suspension. I’ve put it off for awhile, but it’s time. The other day I put the car on stands and took a measurement of the pinion angle; it was +1* up, which is terrible, especially for a poly bushing deal. I bought the upr pro extreme kit some time (probably close to 16 months) ago at a race over at sgmp and I’ll be installing it this week. Doubt I’ll get to the arb, but everything else should be easily doable in a day.

The arb is kind of overkill for what I’m doing, but that’s ok.

Got the uppers and lowers put in, as well as some solid upper bushings. Today was hot as hell so I got started at around 7:30am. Still miserable though. One thing I didn’t realize was the upr control arms have 1/2in hardware, so it made it a little trickier getting everything in, but it worked out with some persuading.

Old bushings were in terrible shape, like hot dog down a hallway bad.

Some of the bolts weren’t in great shape either.

Upper housing bushings weren’t as bad, but still not good by any stretch.

I set the pinion angle at 1.2* down, so I’ll see tomorrow how it does.

All in all, not a bad days work.

Old bushings were in terrible shape, like hot dog down a hallway bad.

Some of the bolts weren’t in great shape either.

Upper housing bushings weren’t as bad, but still not good by any stretch.

I set the pinion angle at 1.2* down, so I’ll see tomorrow how it does.

All in all, not a bad days work.

Been enjoying how the car has been with the new control arms and bushings. Was hoping to put the slicks in and go make a hit, but the clutch started to give in the top of 3rd and 4th gear.

The new McLeod rxt came in yesterday. It’s definitely the nicest clutch the car has ever had.

The new McLeod rxt came in yesterday. It’s definitely the nicest clutch the car has ever had.

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 110

- Views

- 9K

- Replies

- 3

- Views

- 1K

- Replies

- 14

- Views

- 2K

Progress Thread

2004 Comp Orange GT

- Replies

- 9

- Views

- 2K