I got the woman back from the hospital today at about 4:30, so I had to go work on Booger to make her happy........y'all thought I was doing this for me?

Anywho......I didn't think I was going to be able to work on him, so I left half my tools at work

.

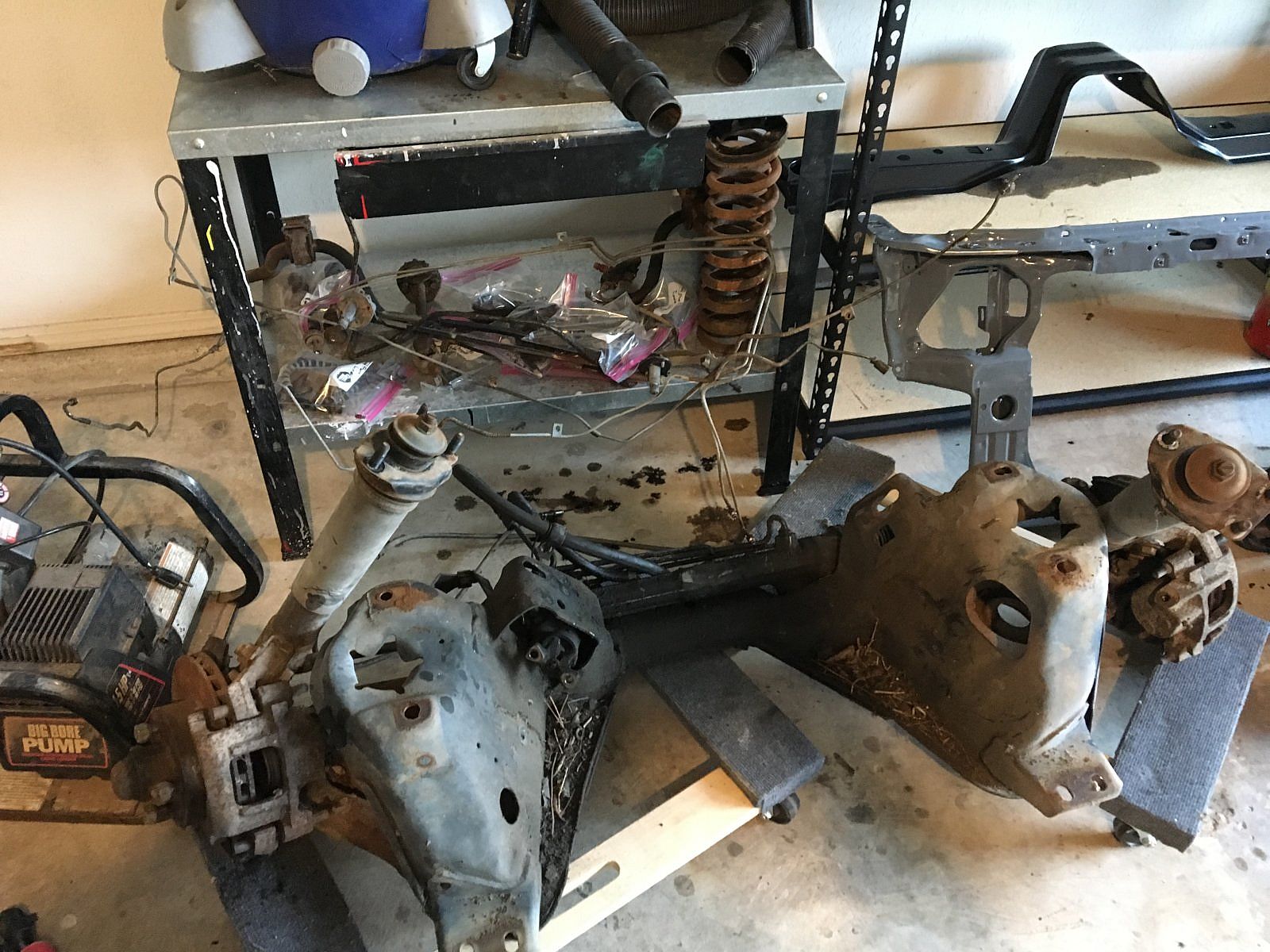

Not to be daunted by such hum-drummery as no correct tool on hand I went after the wiring harness first. It's out of there! No more old wiring for Booger! That shelf has pretty much all of the leftovers of the interior. Those springs are from the IRS, don't start.......

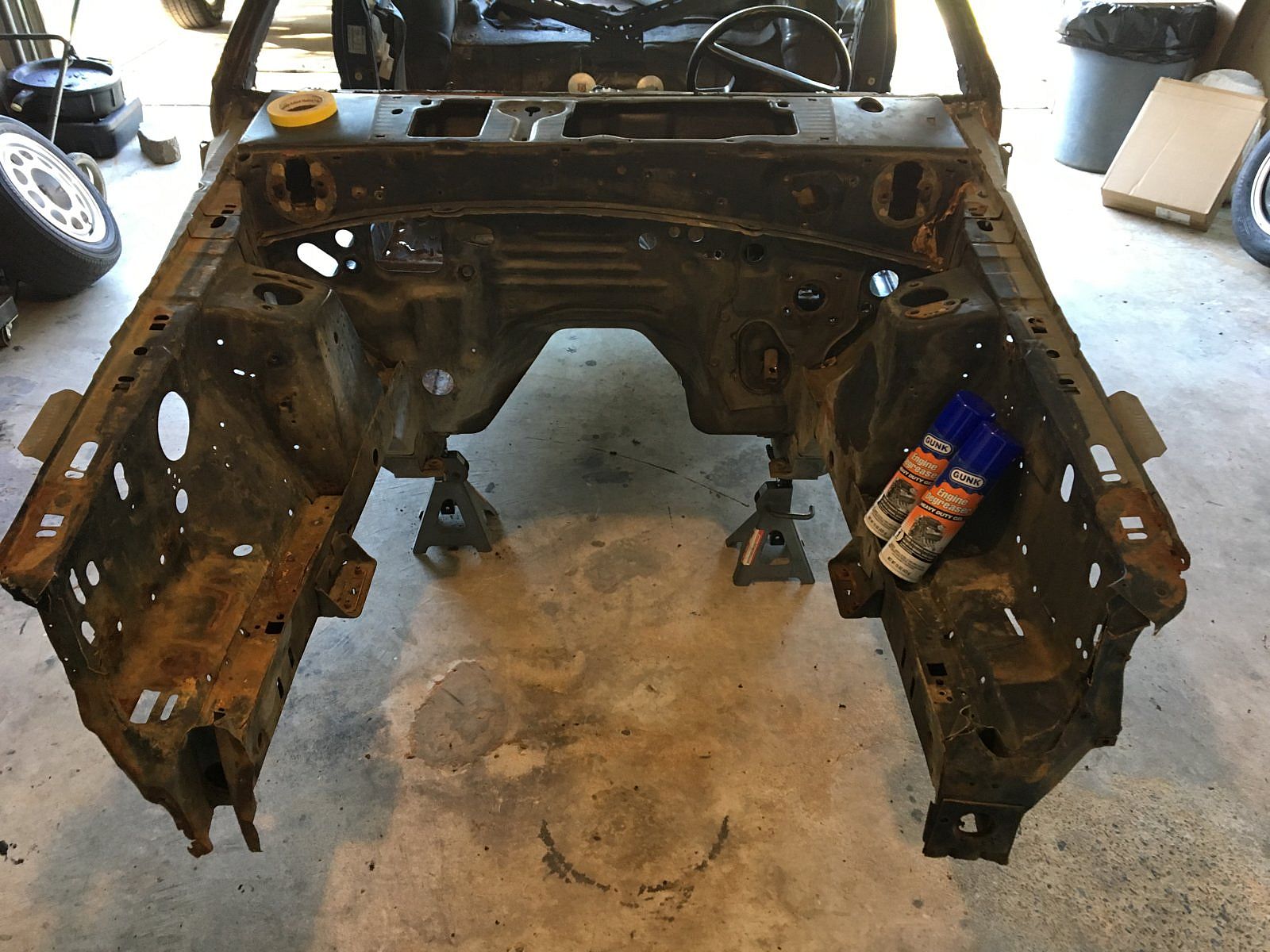

Not only did I pull out the harness, I cleaned up the interior. Well......sort of. I still found more change, maybe $2-3. It's been buried under the factory matting. I vacuumed out the loose rust, leaves, rat crap, a couple jihadists, you know, the usual.

I was going to take out the four simple to get to nuts

holding the booster on. Yep, that's what I was going to do alright

.

I could get to the lower left, easy peasy, lemon squeezy. The other three, on the other hand, need about a 12" extension to reach them. Guess what's not at home?

So tomorrow I'll pull the booster.

I did clean up most of the butyl tape around the windshield too and vacuumed out the the cowel. It was chock full of stuff. Ain't no more.

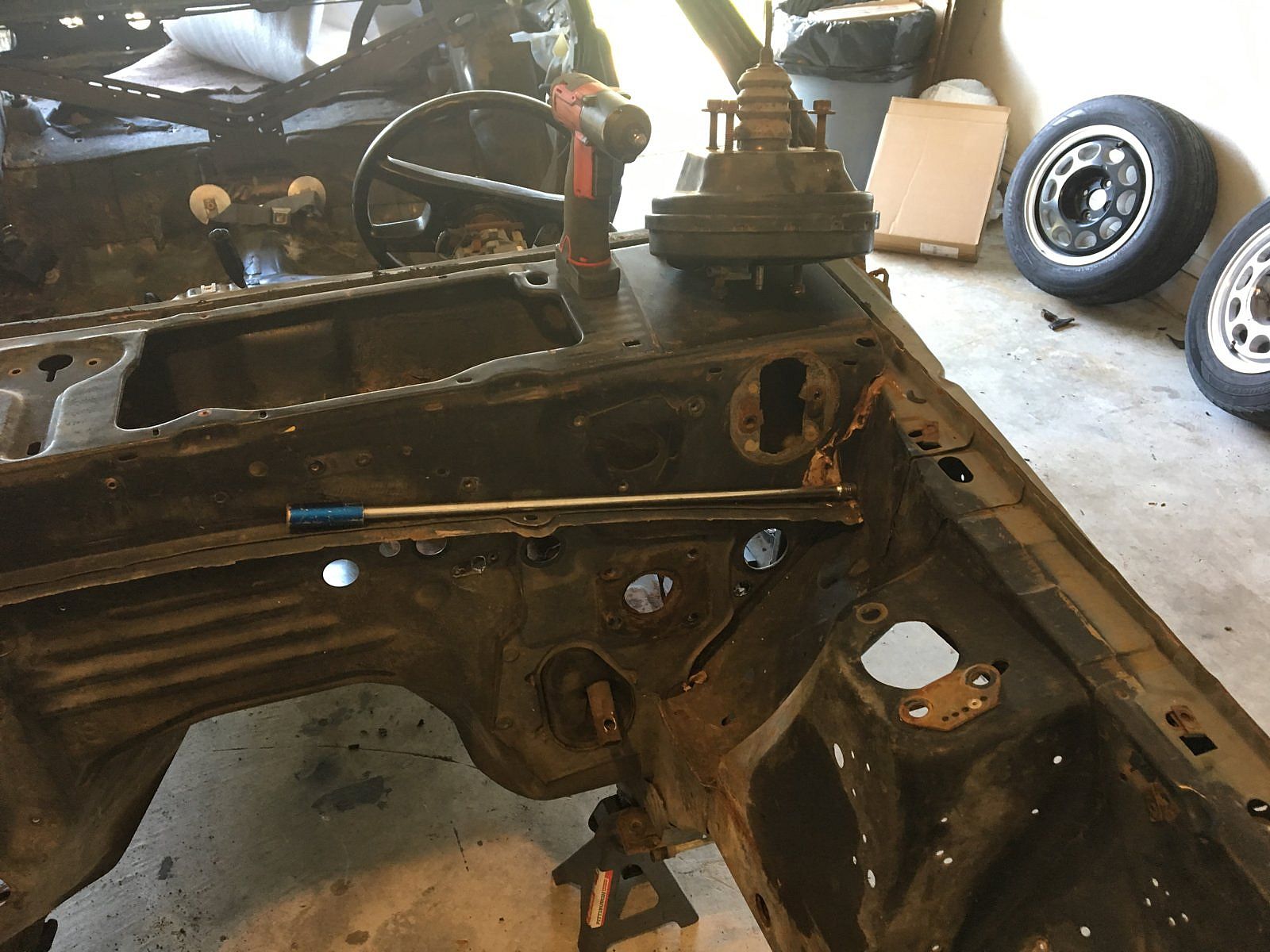

Here's a few pictures of the floor pan, lovely eh?

Remember that really cool plasma cutter I bought and have been practicing with? The outlets in my garage keep blowing when I use it

.

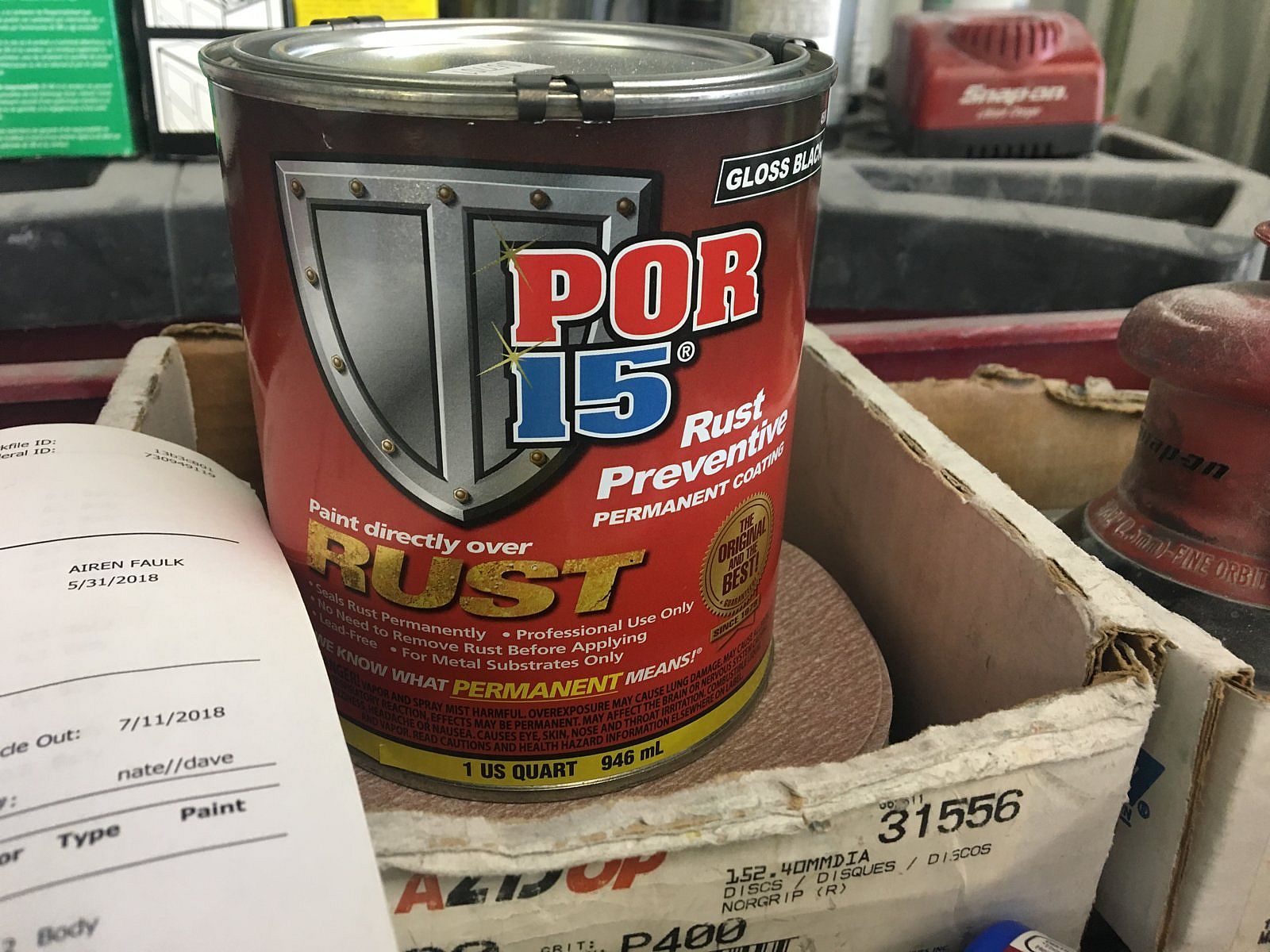

Tomorrow after I get the booster out I will finally scrub the engine bay and make my eb drawing and measure the crap out of things in preparation for the frame rail.

So, maybe this weekend I'll be doing some serious cutting! Yay! All I want for Father's Day is someone to fetch the beer for me and enough argon for my welder to keep going.

.

.