dz01

Member

I thought I would share my personal experiences chasing the dreaded surging idle problem. I’ll first disclose that I’m by no means an expert or professional mechanic. I turn a wrench as a hobby and leverage the skills and talents of many folks on this board to steer me in the right direction. I can honestly say after close to 3 years of chipping away periodically at night and weekends here and there, I finally fixed my idle problems AND got rid of Codes 41 and 91!

I’ve gone down many, many rabbit holes and replaced many parts I probably didn’t necessarily need to. However, I’m just going to focus on the areas where I found problems which ultimately led to me fixing the problem.

Issue:

Hanging idle when decelerating, rev the car up when sitting idle and takes a while for the RMPs to come back down. Car also didn’t idle smooth. Sometimes high and sometimes low. Also had codes 41 and 91 (running lean) which caused my gas mileage to plummet. Not a huge deal since this is a weekend car, but was annoying.

Problem later turned into stumbling at idle when coming to a stop

Actions:

I started with the surging idle checklist. Like I mentioned before, I’m only going to share what worked, not all the parts I changed and tweaks I made.

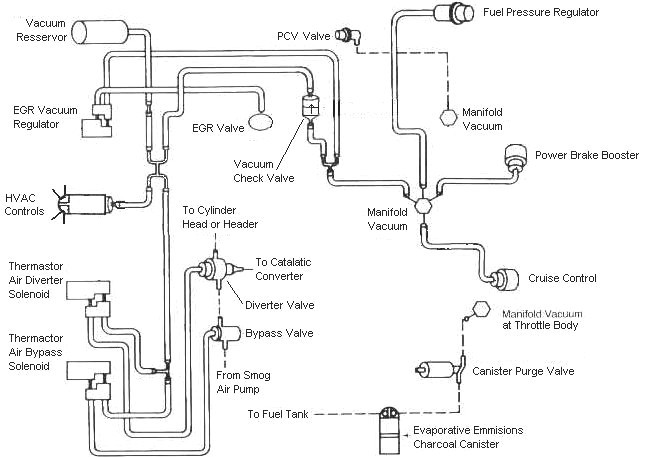

1. Vacuum leaks

Even though I solved all my vac leak problems, I was still pulling codes 41 and 91. My idle was much better, but I now created a problem where the car would stumble pretty bad when coming to a stop. Car would struggle to stay running for about 10 seconds, then idle fine again. After ruling out a number of things and based on similar symptoms from another mustang owner, I went after the TAB/TAD.

2. TAB/TAD (need to be added to the master surging idle checklist)

3. Diverter Valve

So I’m code free and car runs great!

Lots of people helped steer my in the right direction and gave advise on how things are supposed to work. Hopefully this post will help someone else down the road. My first issue is likely common, but I’m sure not many will run into the second and third. Previous owner didn’t have excellent attention to detail!

I’ve gone down many, many rabbit holes and replaced many parts I probably didn’t necessarily need to. However, I’m just going to focus on the areas where I found problems which ultimately led to me fixing the problem.

Issue:

Hanging idle when decelerating, rev the car up when sitting idle and takes a while for the RMPs to come back down. Car also didn’t idle smooth. Sometimes high and sometimes low. Also had codes 41 and 91 (running lean) which caused my gas mileage to plummet. Not a huge deal since this is a weekend car, but was annoying.

Problem later turned into stumbling at idle when coming to a stop

Actions:

I started with the surging idle checklist. Like I mentioned before, I’m only going to share what worked, not all the parts I changed and tweaks I made.

1. Vacuum leaks

Let me start off by staying don’t waste your time with carb cleaner, spraying oil, or using propane to detect vac leaks. Unless you specifically know where your problem is, this is a huge waste of time. You’ll never hit all the areas successfully where a vac leak could occur and you’ll forever be getting responses from people telling you that you have a vac leak based on your symptoms. Might as well do it right and rule it out completely.

Borrow, rent or build an emissions smoke detection machine. I had the benefit of borrowing a snap-on smoke machine from a mechanic friend. Worked great! First round I identified a cracked upper intake plenum. The back bolt must have been tightened too tight by previous owner and snapped the intake in 3 pieces. Huge leak! Post replacing the intake, I borrowed the machine again and found a leaky EGR (I later found this to be normal- this particular EGR has what’s called a “metered” leak). I replaced it anyway. And I found the butterfly shaft on my TB had a small leak at the bottom. Although probably not a huge deal, I had a brand new TB already and just swapped it out. At this point I decided to make my own smoke machine which is pretty easy to do (check on the interweb for examples). No more leaks detected!

Using a smoke machine, all the leaks I found took less than 2 minutes to identify and it showed me exactly where the issue was. No way could I have accomplished this any other way.

Even though I solved all my vac leak problems, I was still pulling codes 41 and 91. My idle was much better, but I now created a problem where the car would stumble pretty bad when coming to a stop. Car would struggle to stay running for about 10 seconds, then idle fine again. After ruling out a number of things and based on similar symptoms from another mustang owner, I went after the TAB/TAD.

2. TAB/TAD (need to be added to the master surging idle checklist)

I read multiple posts and even heard from a Ford mechanic that the TAB/TAD have nothing to do with idle….this is wrong!

I plugged the TAB vac lines with golf tees and codes 41 and 91 disappeared! I did pull 44 and 94 which was expected. Car ran great! I know it’s easy to pull the smog system, but I prefer to keep it intact at least for now.

After closely inspecting the vac lines going to and from the TAB/TAD, I noticed my vac lines were backwards.

I switched them around correctly and no more code 44 and 94 and 41 and 91 did not return!

I did however throw a new code- #46

3. Diverter Valve

Long story short, after swapping TAB/TADs and bypass and diverter valves trying to trouble shoot this new code 46, the problem ended up being the diverter valve tube that connects to the Cats. Mine tube was missing and the bottom of the diverted valve was capped.

When the valve opened attempting to push air to the cats, but was completely blocked that must have been causing code 46. Nowhere for the air to go.

I uncapped the bottom of the diverter valve and let the air blow into the atmosphere for now. I did pick up a new tube to connect the diverter to the cats, but haven’t put it on yet.

So I’m code free and car runs great!

Lots of people helped steer my in the right direction and gave advise on how things are supposed to work. Hopefully this post will help someone else down the road. My first issue is likely common, but I’m sure not many will run into the second and third. Previous owner didn’t have excellent attention to detail!