You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

-

Sponsors (?)

Middleagecrisis

Active Member

I just checked back in on this thread, so this is too late, but you could have put a cheap oil pressure gauge on the motor to check your oil pressure. I suspect you lost oil pressure somehow, which caused your lifters to start clacking. I've had that happen before on a big block mopar 383, and the symptoms were just as you described.

Well you're in luck, we can teach you all the bad habits you need to succeed.

First, if you're gonna work on this junk, get a assembly manual for your year stang. Not a chiltons or haynes, go to fleabay and find a Ford assembly manual. It will look like this:

I am scared for him. Makes a pit in my stomach thinking when I was seventeen, and screwing up cars by not thinking right. Not having the right tools. Then sending the piece of crap to the junkyard because I messed it up. Back then I was on my own with no help. Even now I have to tell myself to slow down, and think.

Man all my sockets aren't fitting in the hole lol , they are skinny at the top and get fatter at the bottom so I can't get it on the shaft to check if it's seated imma have see if one of my friends have one ,I'm just driving the the old 7.3 powerstroke for now so I can take my time with this and not f*** anything up, for the vertical play idk when I pulled distributor it came up with it so I'm assuming there is some play .How much vertical play is there on the oil pump driveshaft, assuming it's retained by the washer?

I bought one I just need to get a socket that fits in to get on the oil pump shaft , hopefully when I prime it tightens up my rocker arms I feel like they have to much play even though everything is torqued and pushrods are nice and tightI just checked back in on this thread, so this is too late, but you could have put a cheap oil pressure gauge on the motor to check your oil pressure. I suspect you lost oil pressure somehow, which caused your lifters to start clacking. I've had that happen before on a big block mopar 383, and the symptoms were just as you described.

Do you have ANYONE who could possibly help you?? Friend, uncle, parent who has some mechanical skill?? From what You have posted here, it seems you would really be better off Learning with someone watching over you, showing you what NOT to do before you end up a pile of scrap metal.. We have all been there before.......

Yes, nothing you can't handle.When I do it am I supposed to have the drill going counter clockwise?

nope im solo lol , except for all y'all helping and YouTubeDo you have ANYONE who could possibly help you?? Friend, uncle, parent who has some mechanical skill?? From what You have posted here, it seems you would really be better off Learning with someone watching over you, showing you what NOT to do before you end up a pile of scrap metal.. We have all been there before.......

Ditto thisOn every stock 5.0 I've taken the factory rockers were a little loose. Have you tried using a drill to prime your oil system? Once you get everything pumped up the rocker might tighten up.

- Mar 2, 2015

- 6,822

- 5,858

- 203

You cam make one from an old Ford distributor. You take the gear off, remove from distributor, and cut the shaft. Grind it down to fit on a drill.

I've used a quarter inch extension for a 1/4 inch bit. The one with the thin magnet end, not the bigger locking type. Just like the screw driver bit holders.

I've used a quarter inch extension for a 1/4 inch bit. The one with the thin magnet end, not the bigger locking type. Just like the screw driver bit holders.

Monkeybutt2000

Mustang Master

That's exactly what I use,works great.You cam make one from an old Ford distributor. You take the gear off, remove from distributor, and cut the shaft. Grind it down to fit on a drill.

I've used a quarter inch extension for a 1/4 inch bit. The one with the thin magnet end, not the bigger locking type. Just like the screw driver bit holders.

Didnt think of that I've been waiting for March 2nd for the tool to come in the mail I got an extra distributor so I might try this laterYou cam make one from an old Ford distributor. You take the gear off, remove from distributor, and cut the shaft. Grind it down to fit on a drill.

I've used a quarter inch extension for a 1/4 inch bit. The one with the thin magnet end, not the bigger locking type. Just like the screw driver bit holders.

Middleagecrisis

Active Member

I bought this oil pump priming tool (Mellings PT11) from Jeg's for $22 that looks like it will work perfect and save you from ruining a perfectly good distributor:Didnt think of that I've been waiting for March 2nd for the tool to come in the mail I got an extra distributor so I might try this later

Melling PT11: Oil Pump Priming Tool Small Black and Big Block Ford - JEGS High Performance

TOOL-PRIMING

Yes, nothing you can't handle.

I bought I'm trying to use it now , im trying to get it on the shaft but when is spin right it feels tight like it won't spin lbut when I do it left (counter clock wise ) It spins but it feels like it's not on the shaft , is there any certain way to do it?I bought this oil pump priming tool (Mellings PT11) from Jeg's for $22 that looks like it will work perfect and save you from ruining a perfectly good distributor:

Melling PT11: Oil Pump Priming Tool Small Black and Big Block Ford - JEGS High Performance

TOOL-PRIMINGwww.jegs.com

CAMTWO1070

Active Member

Ive found that in todays world nothing is made of good quality anymore. I built an engine for my stang and i read alot of people havinge issues with loose rocker arms after doing an adjustment and heres the reason Ive come up with........

No quality control.........I took my brand new Comp Cams lifters apart after hearing horror stories on numerous sites about lifter failure and I found that inside 13 lifters there were different amounts of machine oil and 3 were completely dry.......

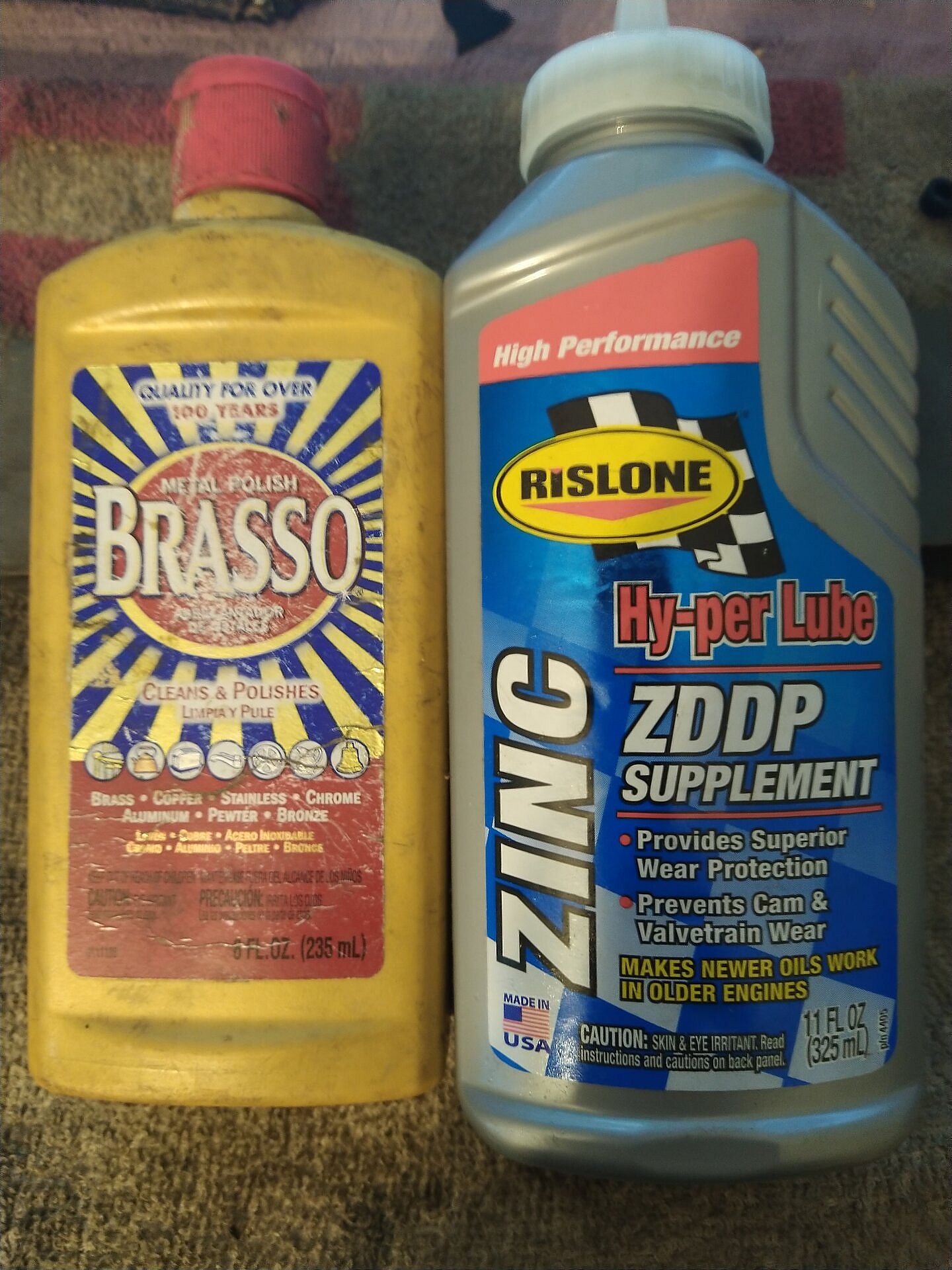

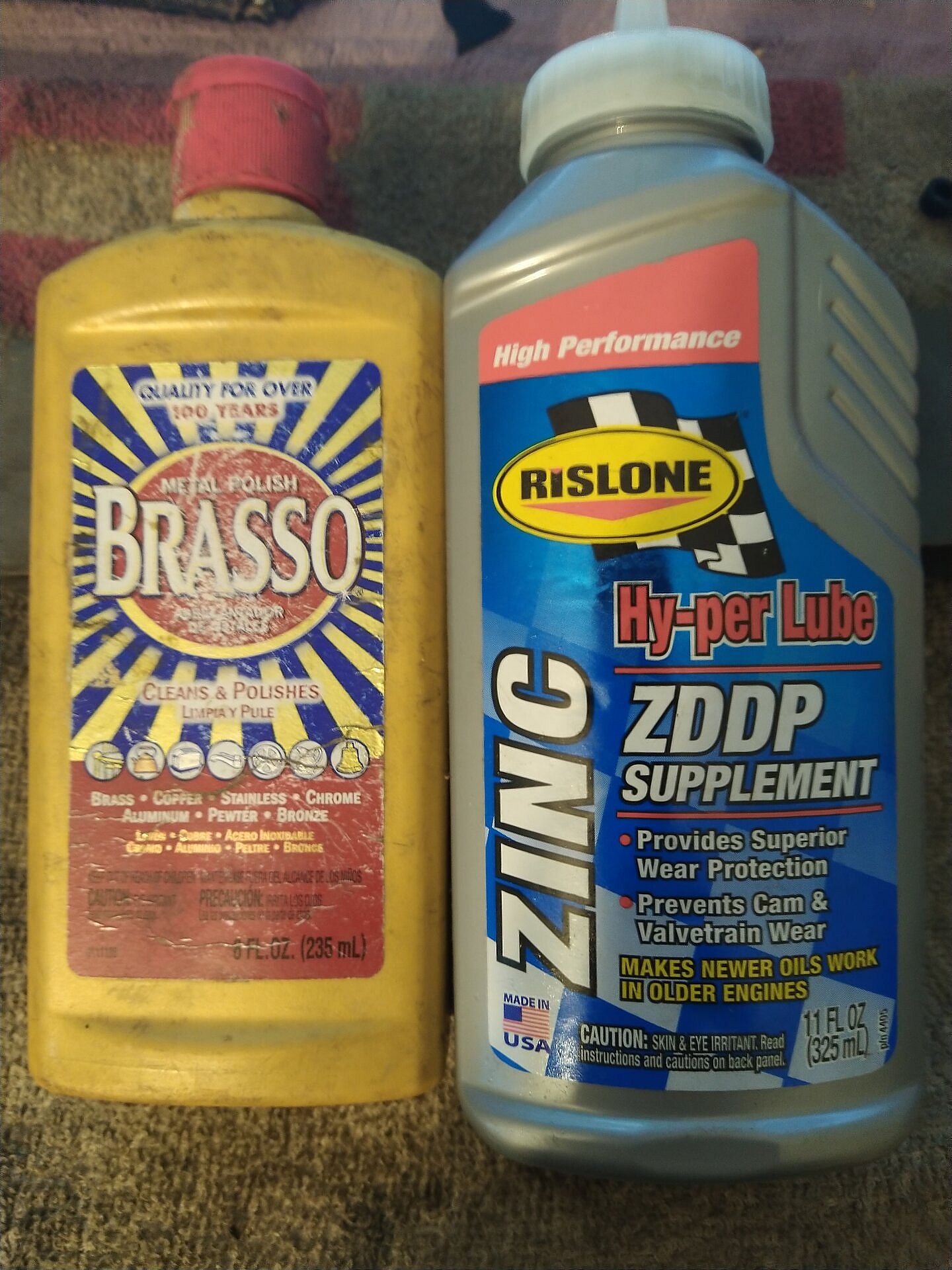

I cleaned them all out in an ultrasonic cleaner and polished each lifter body, each internal plunger and each lifter cup with Brasso Metal Polish then I added 35 drops of ZDDP oil additive to each body and set each lifter plunger using a needle on the valve so they can be set 1/2 turn without lifting the valve......

I set the valves to Comp Cams specs then I slap on the primer tool and spin it counterclockwise and while spinning the oilpump I also spin the engine twice over using a breaker bar on the crankshaft pulley bolt to get every lifter properly pumped up aswell as each bearing properly lubed...........

Everything went very well for break-in with zero issues and Ive yet to experience any type of valvetrain noise on startup...

No quality control.........I took my brand new Comp Cams lifters apart after hearing horror stories on numerous sites about lifter failure and I found that inside 13 lifters there were different amounts of machine oil and 3 were completely dry.......

I cleaned them all out in an ultrasonic cleaner and polished each lifter body, each internal plunger and each lifter cup with Brasso Metal Polish then I added 35 drops of ZDDP oil additive to each body and set each lifter plunger using a needle on the valve so they can be set 1/2 turn without lifting the valve......

I set the valves to Comp Cams specs then I slap on the primer tool and spin it counterclockwise and while spinning the oilpump I also spin the engine twice over using a breaker bar on the crankshaft pulley bolt to get every lifter properly pumped up aswell as each bearing properly lubed...........

Everything went very well for break-in with zero issues and Ive yet to experience any type of valvetrain noise on startup...

Attachments

Okay my shaft is gone  I tried to get with a magnet but just made it worse . What should be my course of action

I tried to get with a magnet but just made it worse . What should be my course of action

I tried to get with a magnet but just made it worse . What should be my course of action

I tried to get with a magnet but just made it worse . What should be my course of actionLikely the oil pump shaft has dropped (hopefully) down into the oil pan. Yes you will be pulling the engine. I have heard of people that claim to have fished it out of the oil drain plug hole then used a vacuum line attached to one end of the shaft to insert it back into the pump from the top but I'm suspect of this method.

How mechanically inclined are you?

How mechanically inclined are you?

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 16

- Views

- 1K

Progress Thread

H/C Swap Problems/Ideas

- Replies

- 3

- Views

- 403

- Replies

- 24

- Views

- 3K

- Replies

- 13

- Views

- 3K