Now this is an example of what I'm talking about.

How did the car run before the dyno session and what did the operator look at and change, details.

One of the things specifically with fuel injectors that many people including some tuners, don't consider and [also] why I puke in my mouth a little bit when someone mentions "tuned" mass air meters:

Alternate titles for this explanation:

One reason why tuning fuel injection mechanically is not ideal

Why I picked up 50 HP from just a tune

1. Physical Variance in Injector Slope

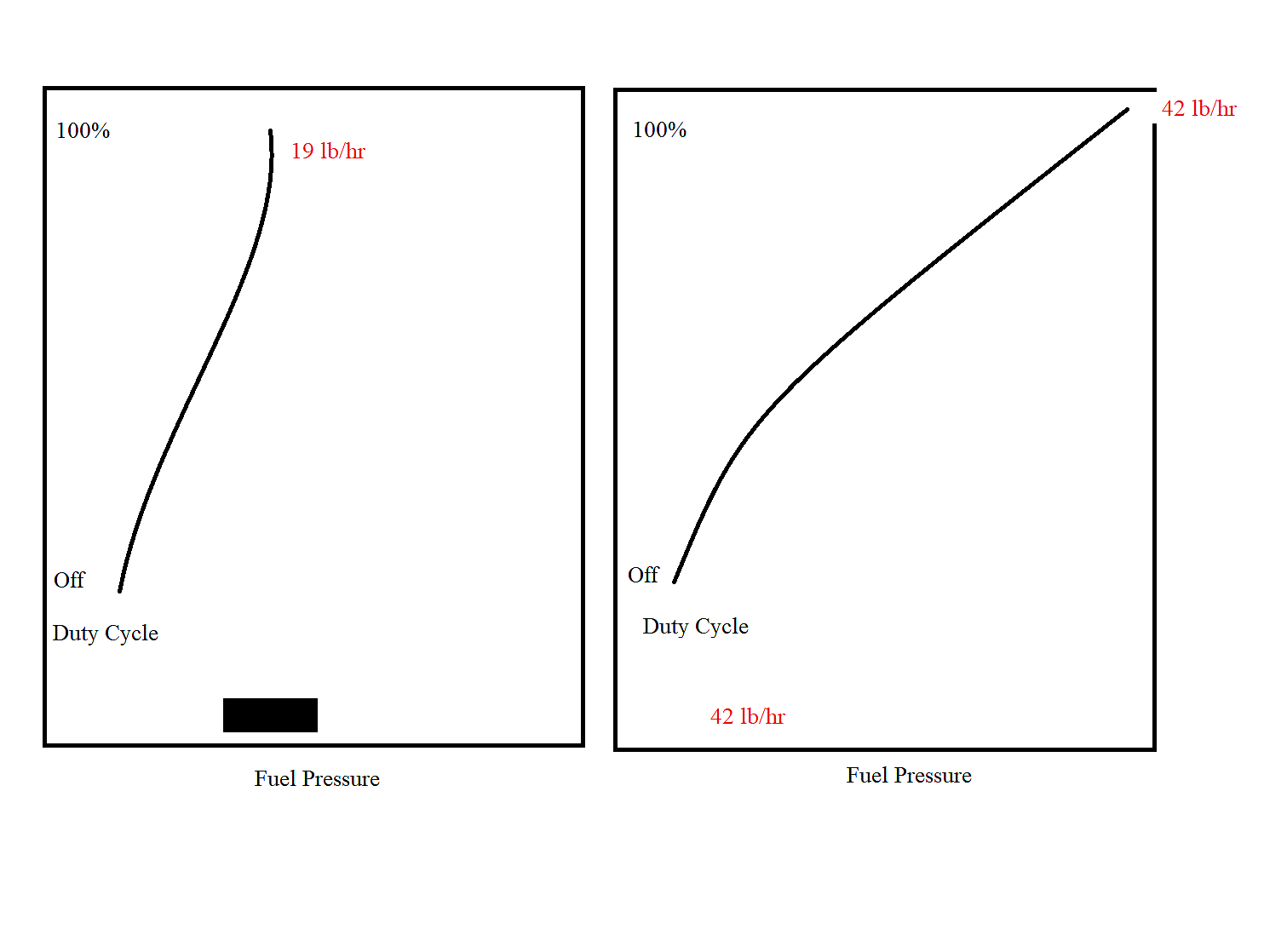

This is a visual representation of the variance that can occur between to physically different size injectors. Note that each of these slopes takes place within the same 0-5V range. The 19lb injector will of course, get to a full 5 volts faster and more often than a 42 lb injectors. Note also that no injector flows linearly from zero percent duty cycle to 100%. That non-linear injector flow [will] vary depending upon the pressure and volume of the fuel supply. The curves in the slope will change.

Most of us should know this: Fuel injectors were each designed for an optimum spray pattern at a given pressure. This isn't make or break for an injector but is certainly a factor. An ECU is programmed/designed to cooperate with and make efficient use of this slope under predetermined conditions (fuel pressure, volume, etc.).

2. Mass Air Meter Sampling and Resolution

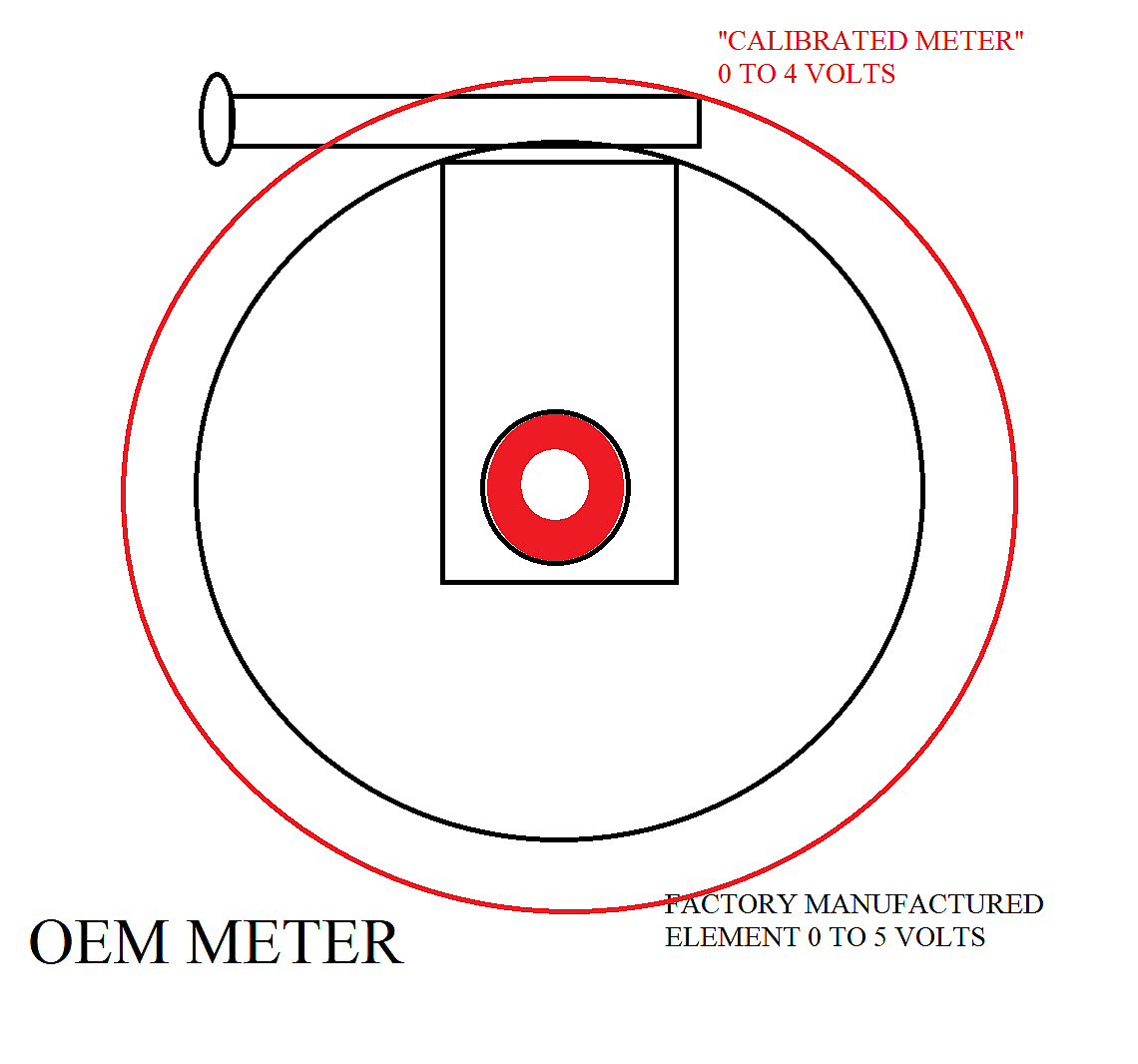

When looking at this image, the [red] bit only exist in a "calibrated" meter. Any other or [normal] meter will have only the portions in black. The sensor is housed within a fixed sample tube. A portion of the sample tube is in the air stream and is optimized to produce a smooth flow pattern over the sensor element. The entire assembly is flow tested and optimized to use as much of the 5V range as is efficiently possible. This is to maximize the resolution of the meter. The more points you have to reference in the 0 to 5-volt range the more sample accuracy you have to match to a specific point in the preprogrammed table in the ECU. More points of reference = more exact and larger number of ECU responses to a given voltage. Full steps, half steps, quarter steps, etc...

Let's take a mass air meter and 'calibrate it' for larger injectors. The result is the [red] cover you see over the sensor element in the image above. We have to reduce the air sample size in order to 'fool' the ECU into thinking there is less air being sampled than before because at any given voltage, our injector to piss out a lot more fuel. This effectively reduced our maximum voltage from the sensor element. We now have to take all of our readings from within a smaller range (say, 0 to 4 volts for the sake of explanation). We just lost our [eighth] steps (resolution). altered the flow pattern over the sensor, and done nothing to address the variances in slopes of out different size injectors. The larger the difference in the size of the old and new injectors is [directly] proportional to the variance in their slopes. As the variance in injector size increases so does the variance in their slopes. Increasing fuel pressure [increases] these variances proportionately (i.e. adjustable fuel pressure regulator or fuel management unit). Let's not forget that we're also pushing the spray pattern further away from it's designed optimum in these circumstances.

If we remove our OEM sensor and put it into a larger housing then we're taking a smaller sample overall, of the mass of air passing through the meter. In addition to that, the "calibrated" meter will also include the shroud over the sensor in order to produce the repeatable out-signal necessary to mimic OEM behavior. So, we're taking an even smaller sample of the smaller overall percentage of sample able air volume.

What's great is that it starts and idles pretty decent. I can adjust fuel pressure to maximize power at the top of the RPM range. Even if I peg the meter, it doesn't matter too awful much because, at WOT, all I need to do is keeping adding fuel pressure until the volume increases enough to support the air I'm ingesting.

---OR---

I could purchase a meter that is sufficient in size for the amount of air I need for my combo. Put a properly sized sensor within the housing that gives me accurate and repeatable results across the [entire] 0 to 5-volt range with enough of a sensor sample area that I'm maximizing the measure of volume as accurately as possible and excluding turbulent portions of the assembly that might feed false data about actual volume.\

These are your Pro-M and PMAS and BigBore etc. meters.

They have a very reliable, repeatable transfer function that provides the widest resolutions and largest number of reference points possible in the 0 to 5-volt range. Many are as good as and some are much better than OEM in doing these things not to mention, that most are shipped with very detailed transfer functions with multiple point calculations.

For the sake of argument; If I buy a new MAF and it comes with a 30 point transfer function and a 15 point transfer function and I can use either one: Which one would I use? Which one would be the most accurate with the largest set of air volume reference points?

This is where digital tuning comes in:

I take my brand new, oversized 3000 cfm, Big Bore MAF, and read the 0 to 5-volt, 30 point transfer function from the slip of paper and input it into tuning software. I match these given output voltages to a given injector slope for the X sized injector that I'm about to install. So, no matter the load or commanded AFR becomes, I've got all the accurate data loaded into the EEC and accounted for the variances in both: Air Volume sampling and injector size and slope variation. The EEC now has the information necessary to command the [exact] duty cycle to the injector for the demand.

Now, having said all of that: It is also common practice to vary the fuel tables in order to make up for some deficiencies in measuring and metering equipment. In other words: I can adjust some things to help compensate for a crappy meter that only has a reliable transfer curve between .75-volts and 4.2-volts. I can also adjust some things to accommodate variations in the injector slope (i.e cheap injector or injector pushed outside of specification). These changes will help bring things closer but are not as accurate and [still] requires digital tuning.

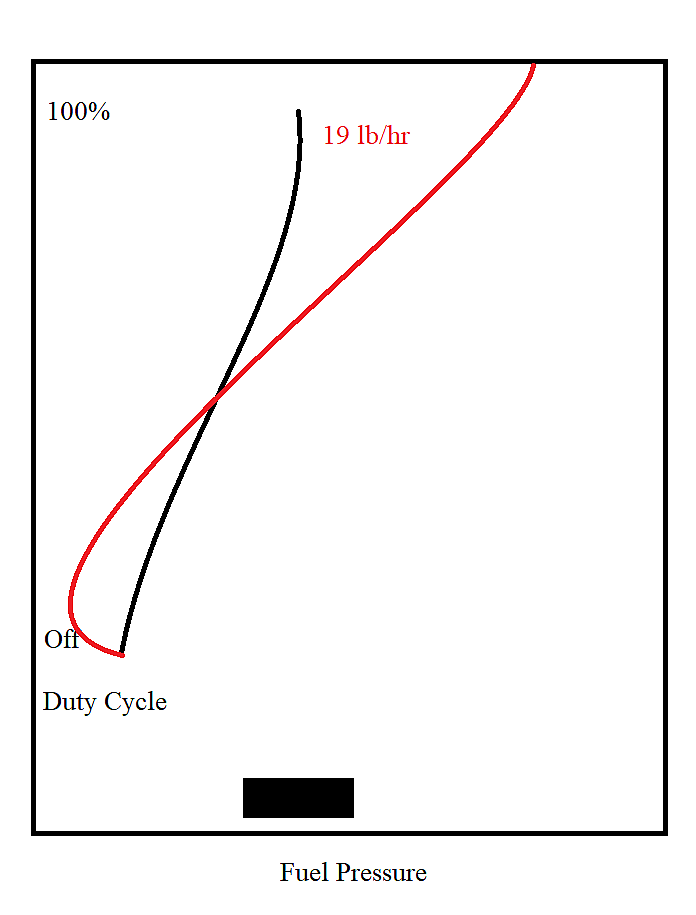

Just for a visual representation: This is what an injector slope might look like when you increase pressure on a given injector. The amount of exaggeration between the lines would be more or less, depending on how far away fuel pressure is from the designed specification:

At least there will always be one "sweet spot" where the car will run great and make the most power.

Generally, that sweet spot, or intersect, is pushed to WOT (I can't imagine why).

I generally avaid these discussions because it takes sooooooooooooo long to put together a decent explanation. By tuning the vehicle, you're maximizing best possible resolutions of your sensors and output devices by making use of the entire range of each.

This is also a pretty good explanation of why you guys sometimes see me arguing against oversized injectors. It pisses away available increments of precision of that injector. The same with Mass Air Meters or any other sensor that you have to "cheat" or "scale" in order to make it work correctly for the application.

Digital tuning allows full capabilities of each of these components in order to make it better than "close enough".