hmm i hope they do me right, ill check with them and see if they know what their doing, im taking the head to them fridayThis guy opened up and polished his chambers on a N/A head and put it on his 2.3T motor. He said he opened it up to 67cc's and that gave him a 7.6 compression ratio.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey whats up! More 2.3 power needed

- Thread starter Piranahbite

- Start date

-

Sponsors (?)

Guys, I have started the assembly process on the turbo 2.3! right now I only have the parts for the short block, but it's going pretty smooth, I have the crank and bearings in place, not sure if the main cap bolts are Torque-to-yield like the head bolts are, but tomorrow when I get the oil pump ill tighten it all down unless I need new main cap bolts. I also don't know how I'm supposed to set the piston ring gaps/orientation. my repair manual is for 1979-1993 Mustangs and doesn't really crack down on 2.3 turbo specifics much less anything under the head gasket so I'm at the internet's mercy when it comes to technical information. if anyone has torque specs for me that would be great!

evintho

Dirt-Old 20+Year Member

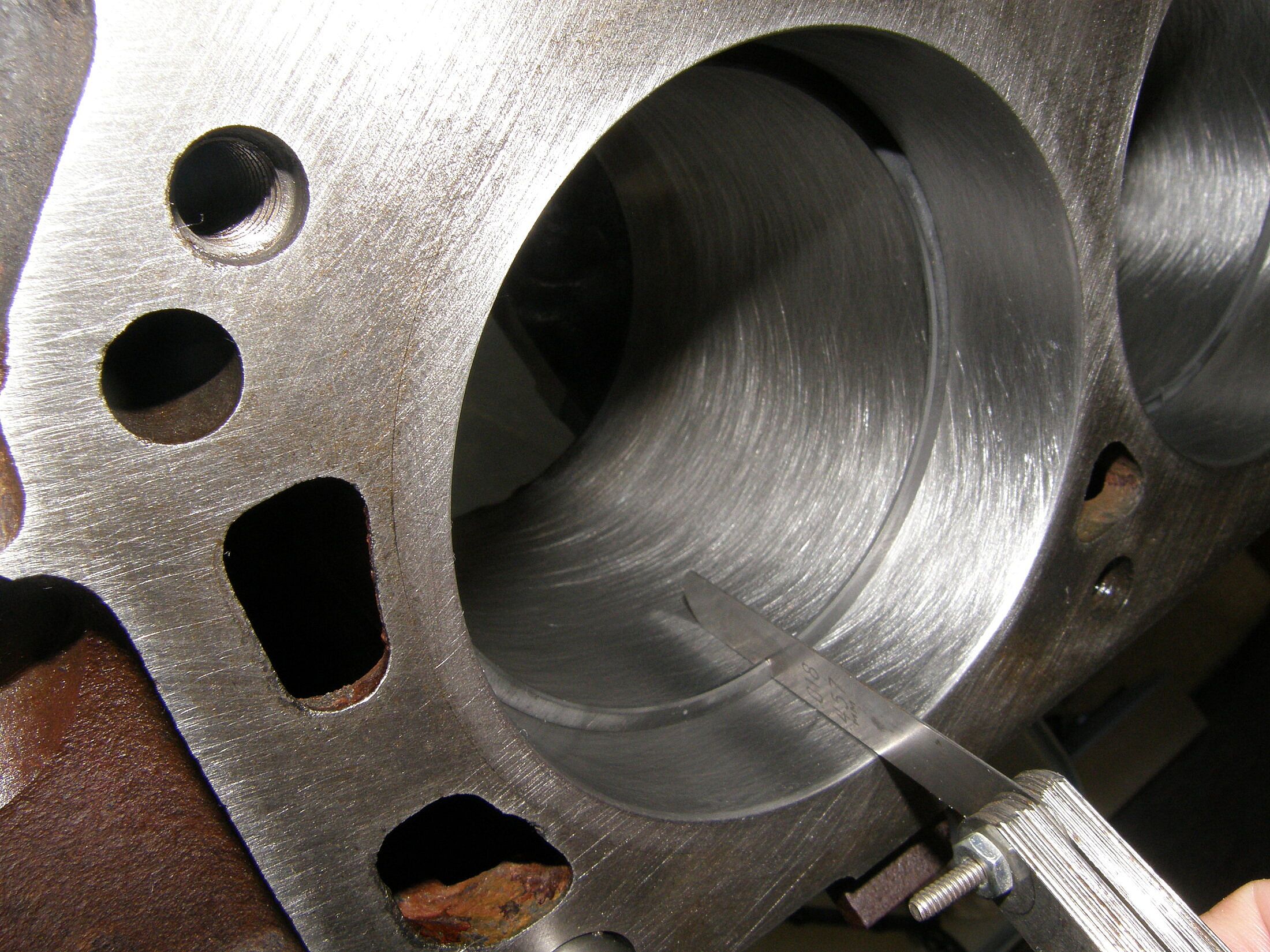

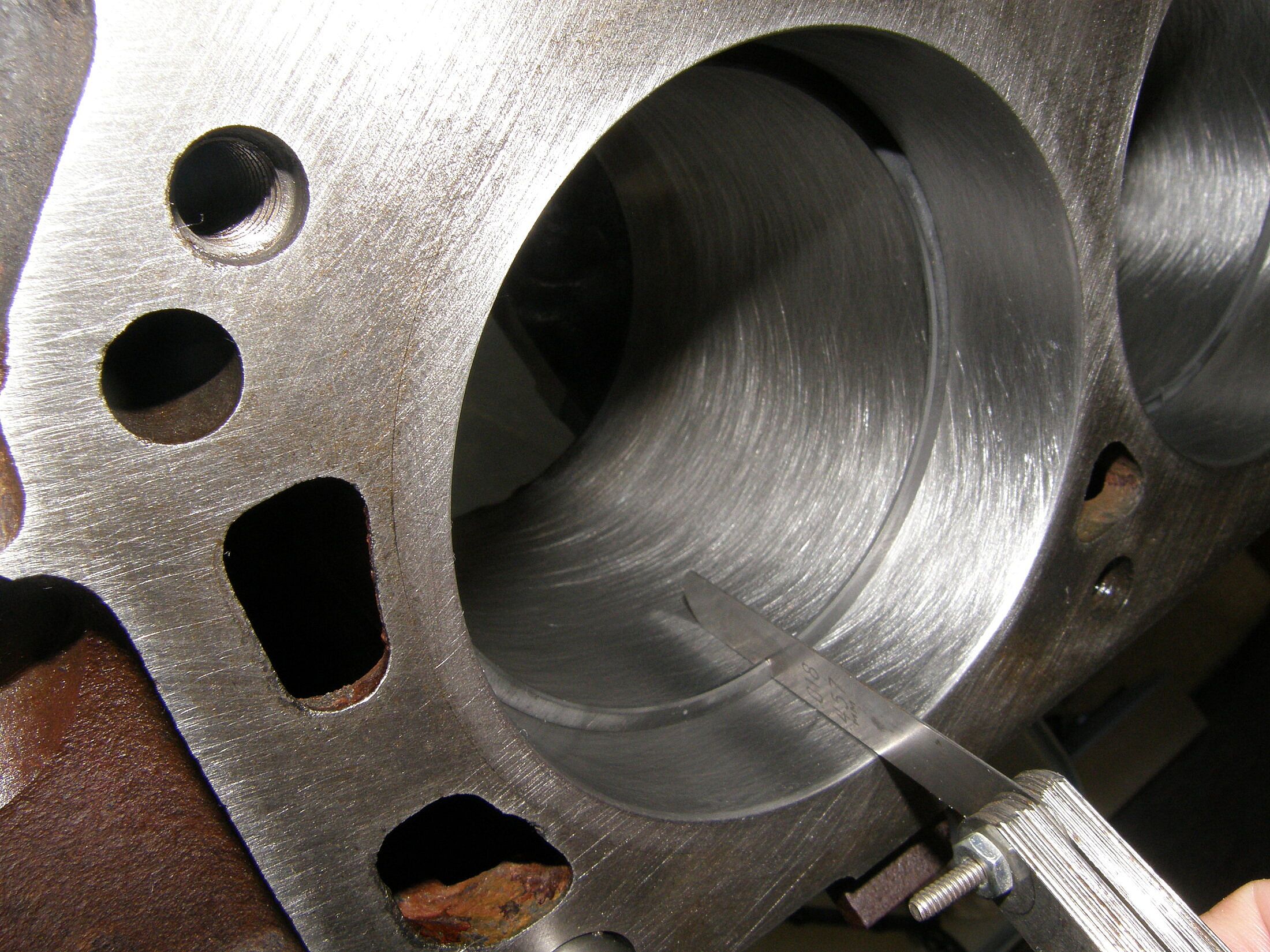

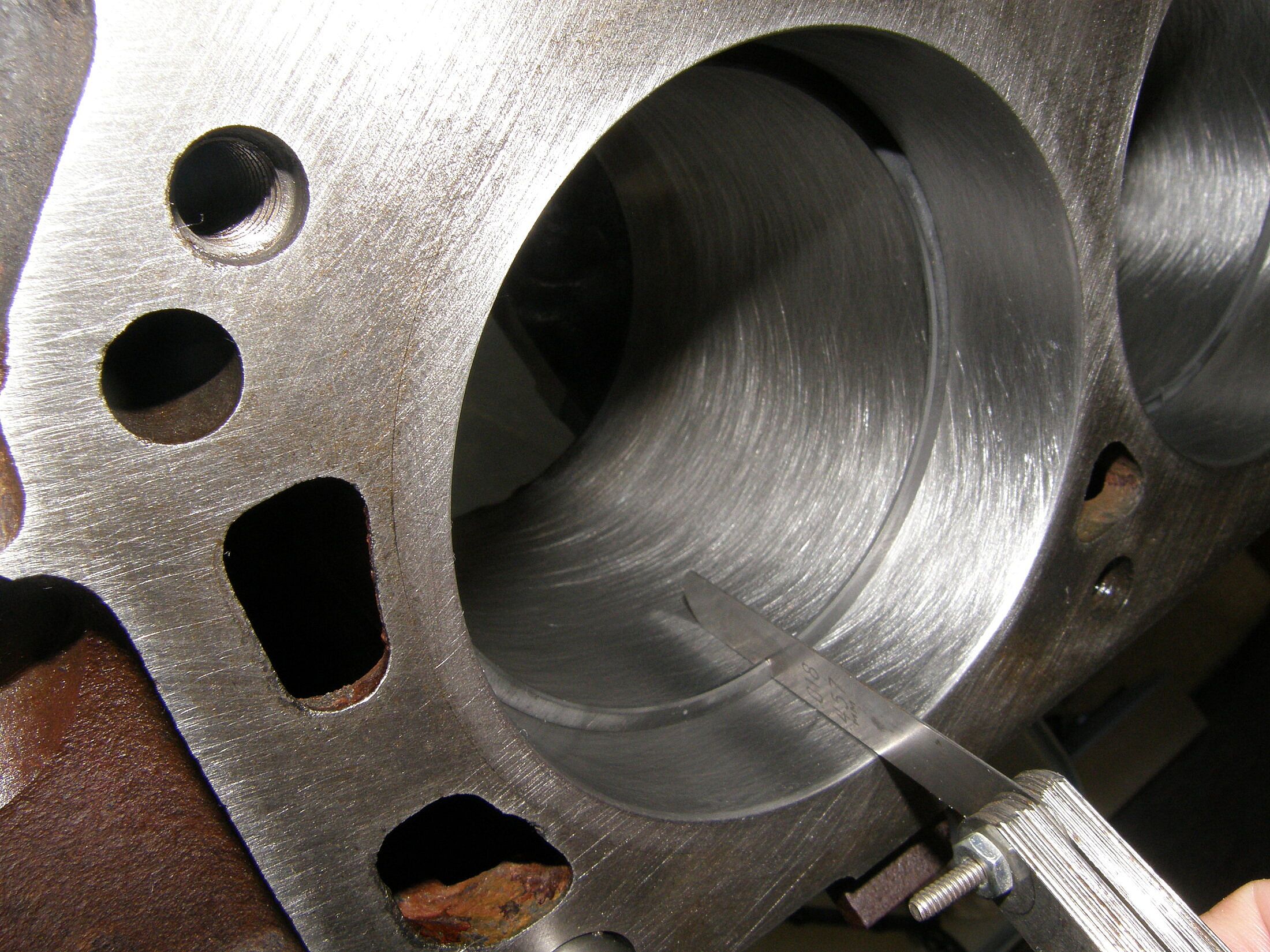

Ring gaps are 0.015-0.020. Set your ring in the bore, square it with a piston and push it down about an inch, then take your ring gap. This is on my 5.0 but it gives you an idea.......

With rings installed on the piston, stagger the gaps. Top ring at 12 o'clock, 2nd ring at around 4 o'clock and oil ring around 8 o'clock.

Main bolts are NOT torque-to-yield so you're good there. Torque the mains in two stages. Go to 60 lbs the first time then go to 85 lbs the final time. Same with the rod bolts. Two stages. 25 lbs the first time then 36 lbs the final time.

With rings installed on the piston, stagger the gaps. Top ring at 12 o'clock, 2nd ring at around 4 o'clock and oil ring around 8 o'clock.

Main bolts are NOT torque-to-yield so you're good there. Torque the mains in two stages. Go to 60 lbs the first time then go to 85 lbs the final time. Same with the rod bolts. Two stages. 25 lbs the first time then 36 lbs the final time.

thanks!! puting it together nowRing gaps are 0.015-0.020. Set your ring in the bore, square it with a piston and push it down about an inch, then take your ring gap. This is on my 5.0 but it gives you an idea.......

With rings installed on the piston, stagger the gaps. Top ring at 12 o'clock, 2nd ring at around 4 o'clock and oil ring around 8 o'clock.

Main bolts are NOT torque-to-yield so you're good there. Torque the mains in two stages. Go to 60 lbs the first time then go to 85 lbs the final time. Same with the rod bolts. Two stages. 25 lbs the first time then 36 lbs the final time.

and should All rings should be in that same tolerance?

my oiler rings are reading .035+ and the wafer ring is too small for the cylinder unless you spread it open

my 2nd ring is reading 0.018 , 0.018, 0.018, 0.018

my 1st ring is reading 0.016 , 0.016, 0.016, 0.018

I Also don't know Wich direction my pistons face, there's an arrow on the head of each one, im assuming to have them point forward?

my oiler rings are reading .035+ and the wafer ring is too small for the cylinder unless you spread it open

my 2nd ring is reading 0.018 , 0.018, 0.018, 0.018

my 1st ring is reading 0.016 , 0.016, 0.016, 0.018

I Also don't know Wich direction my pistons face, there's an arrow on the head of each one, im assuming to have them point forward?

Last edited:

heres some info i was able to dig up, its for a mercury (or mekur i cant read) 2.3 turbo

it has ring gaps listed that match what im seeing with my rings

the box that has my rings also says its for a mercury 2.3L (PN: 2M5613

it has ring gaps listed that match what im seeing with my rings

the box that has my rings also says its for a mercury 2.3L (PN: 2M5613

evintho

Dirt-Old 20+Year Member

You're all good. Sounds like all the rings are within tolerances. That Hastings part # comes back for an '87-'88 Turbo Coupe and yes, the piston arrows should point towards the front of the block. Button 'er up!

Any news on your head?

Any news on your head?

Last edited:

yep!, I got everything all buttoned up crank, main bearings main caps, pistons, rings, rod bearings, and oil pump all torqued down. i got a gasket set coming in the mail today for the front main seal / timing cover and I should be able to button up the bottom end by tonight! I lubed evrything with 10w-40 mixed with some STP and I used assembly lube in combination on all the bearings and crank surfacesYou're all good. Sounds like all the rings are within tolerances. That Hastings part # comes back for an '87-'88 Turbo Coupe and yes, the piston arrows should point towards the front of the block. Button 'er up!

Any news on your head?

No news on the head yet I'm going to check in with the place and see if they have any news, I'm hoping its ready by the end of the week ( my dad wants to paint the engine dark ford blue)

I have three different chamber sizes to chose from, 61cc , 62.55 and 67cc BoPort said stock size is 61, the website i linked in a previous post said 62.55cc and the guy who did it prior to me on this forum said 67cc

Swap n motor n trans from a rusted out turbo coupe...with a 3" pass side STINGER exhaust pipe. Use the T-coupe ecu n repin your hareness to use it.You'll have to add a 2nd ACT circuit also and grab the big VAM n E6 exhaust manifold from the T-coupe. I used a repinned MERKUR XR4Ti s.a hareness in my 93 lx with the rebuilt 84 GT T 2.3 engine n T5 trans.It's a BLAST !i got an 1987 2.3 manual hatch!

im having trouble keeping up with traffic and going up hills... a little powerless at times any cheap performance mods i can do?

Last edited:

manicmechanic007

5 Year Member

bro, I almost did that, then I decided to just buy the whole motor because it was 50% off, and do a full rebuild, I am definitely going to need help with the wiring when I'm done building the motor since electricity and sensors are not my forte I have a VAM, im on the hunt for an affordable ECU and a VAM connecter so I can have what I need to make the engine work with my current 2.3 harness I'm buying a new high flow t3 exhaust manifold because the one that came with my motor was cracked.. so figure why not upgrade while im at it? I plan to do a whole 3" exhaust with a sick muffler of some sort, but thats after I get the thing running and in my car and all wired up. I plan to take this thing to the drag strip, I read that the 88 TC ran 15.5 in the 1/4 mile so im hoping that since im putting the same motor in a lighter car, with more power I get to run at least that time.Swap n motor n trans from a rusted out turbo coupe...with a 3" pass side STINGER exhaust pipe. Use the T-coupe ecu n repin your hareness to use it.You'll have to add a 2nd ACT circuit also and grab the big VAM n E6 exhaust manifold from the T-coupe. I used a repinned MERKUR XR4Ti s.a hareness in my 93 lx with the rebuilt 84 GT T 2.3 engine n T5 trans.It's a BLAST !

Last edited:

https://www.stinger-performance.com/store/index.php?route=common/home https://bigrmotorsports.com/ are the IN THE KNOW sources... repin guidebro, I almost did that, then I decided to just buy the whole motor because it was 50% off, and do a full rebuild, I am definitely going to need help with the wiring when I'm done building the motor since electricity and sensors are not my forte I have a VAM, im on the hunt for an affordable ECU and a VAM connecter so I can have what I need to make the engine work with my current 2.3 harness I'm buying a new high flow t3 exhaust manifold because the one that came with my motor was cracked.. so figure why not upgrade while im at it? I plan to do a whole 3" exhaust with a sick muffler of some sort, but thats after I get the thing running and in my car and all wired up. I plan to take this thing to the drag strip, I read that the 88 TC ran 15.5 in the 1/4 mile so im hoping that since im putting the same motor in a lighter car, with more power I get to run at least that time.

Attachments

Last edited:

RANGER roller cams are a great upgrade also..get ahold of CHIP at BIG R or SHANNON at STINGER & tell them your goalsbro, I almost did that, then I decided to just buy the whole motor because it was 50% off, and do a full rebuild, I am definitely going to need help with the wiring when I'm done building the motor since electricity and sensors are not my forte I have a VAM, im on the hunt for an affordable ECU and a VAM connecter so I can have what I need to make the engine work with my current 2.3 harness I'm buying a new high flow t3 exhaust manifold because the one that came with my motor was cracked.. so figure why not upgrade while im at it? I plan to do a whole 3" exhaust with a sick muffler of some sort, but thats after I get the thing running and in my car and all wired up. I plan to take this thing to the drag strip, I read that the 88 TC ran 15.5 in the 1/4 mile so im hoping that since im putting the same motor in a lighter car, with more power I get to run at least that time.

also when you go to fire it up mix some 2 stroke oil in with the gas in the tank....mine fired on the 1st crank n ran on the 2nd crank...are you using the brown or green injectors ?...Also what VAM are u using there are diff sizes ?bro, I almost did that, then I decided to just buy the whole motor because it was 50% off, and do a full rebuild, I am definitely going to need help with the wiring when I'm done building the motor since electricity and sensors are not my forte I have a VAM, im on the hunt for an affordable ECU and a VAM connecter so I can have what I need to make the engine work with my current 2.3 harness I'm buying a new high flow t3 exhaust manifold because the one that came with my motor was cracked.. so figure why not upgrade while im at it? I plan to do a whole 3" exhaust with a sick muffler of some sort, but thats after I get the thing running and in my car and all wired up. I plan to take this thing to the drag strip, I read that the 88 TC ran 15.5 in the 1/4 mile so im hoping that since im putting the same motor in a lighter car, with more power I get to run at least that time.

Last edited:

Iv talked to chip from Big R, hes aware of my story, have not reached out to Stingers people yet... might aswell, gives me somthin to do in classRANGER roller cams are a great upgrade also..get ahold of CHIP at BIG R or SHANNON at STINGER & tell them your goals

im 75% sure im using brown injectors, ill have to measure the VAM for you when I get home, but the engines out of an 88' turbo coupe if it helps and it says BOSCH on the side, and will do with the two stroke gas, I have a lil 5oz container ill just pour in the tankalso when you go to fire it up mix some 2 stroke oil in with the gas in the tank....mine fired on the 1st crank n ran on the 2nd crank...are you using the brown or green injectors ?...Also what VAM are u using there are diff sizes ?

look at that 2nd parts chart I posted ..it will tell you what size VAM you have...I'm THINKN from what u said its the BIG one... The 1st chart tells u which pins "wire" must be moved & to where it also tells you which ones must be added and to where

Last edited:

repin your hareness to fit the ecu.. I used the 88 TURBO COUPE LA3 n repinned my XR4Ti harness

View: https://www.youtube.com/watch?v=FOV-LnBwQ0M

View: https://www.youtube.com/watch?v=FOV-LnBwQ0M

Last edited:

Similar threads

- Replies

- 7

- Views

- 647

- Replies

- 14

- Views

- 2K

- Replies

- 5

- Views

- 1K

- Replies

- 20

- Views

- 3K